| Availability: | |

|---|---|

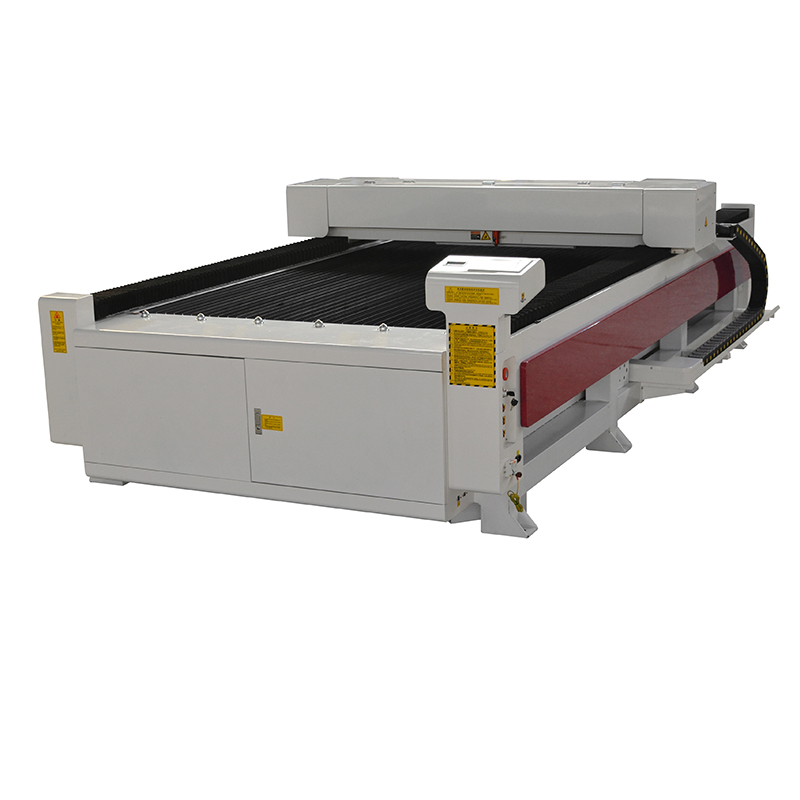

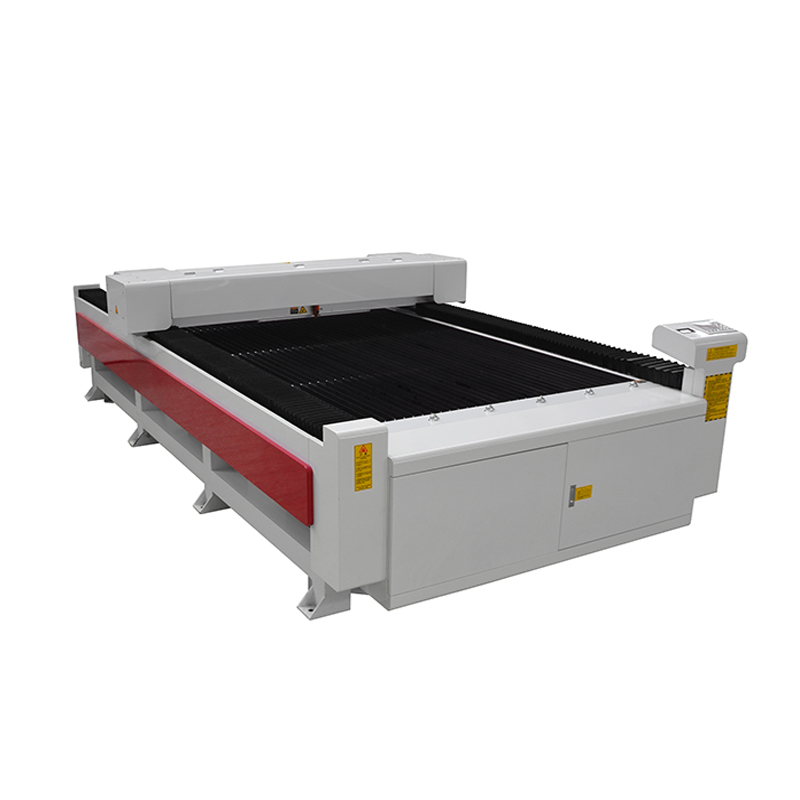

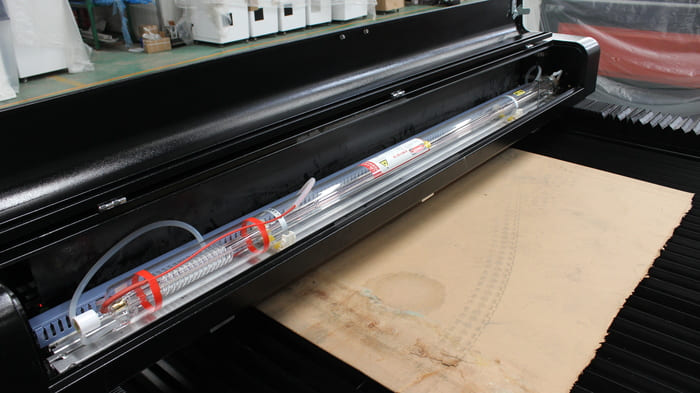

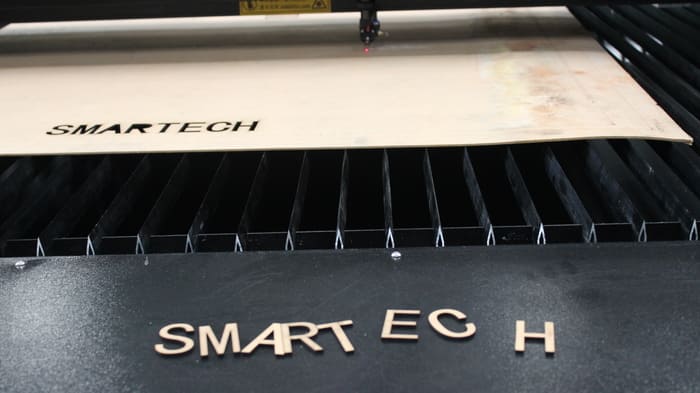

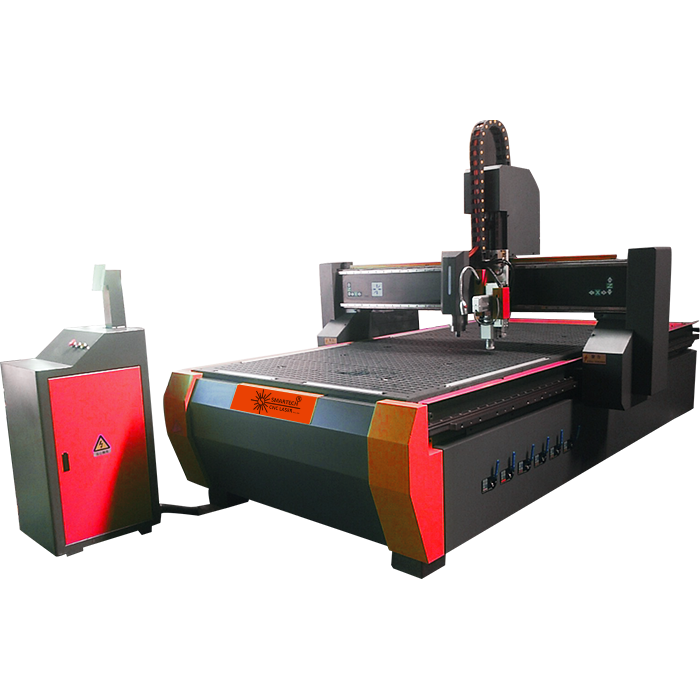

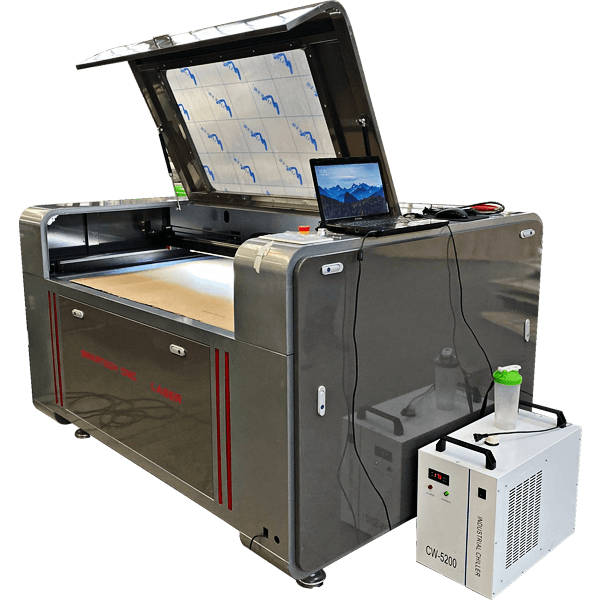

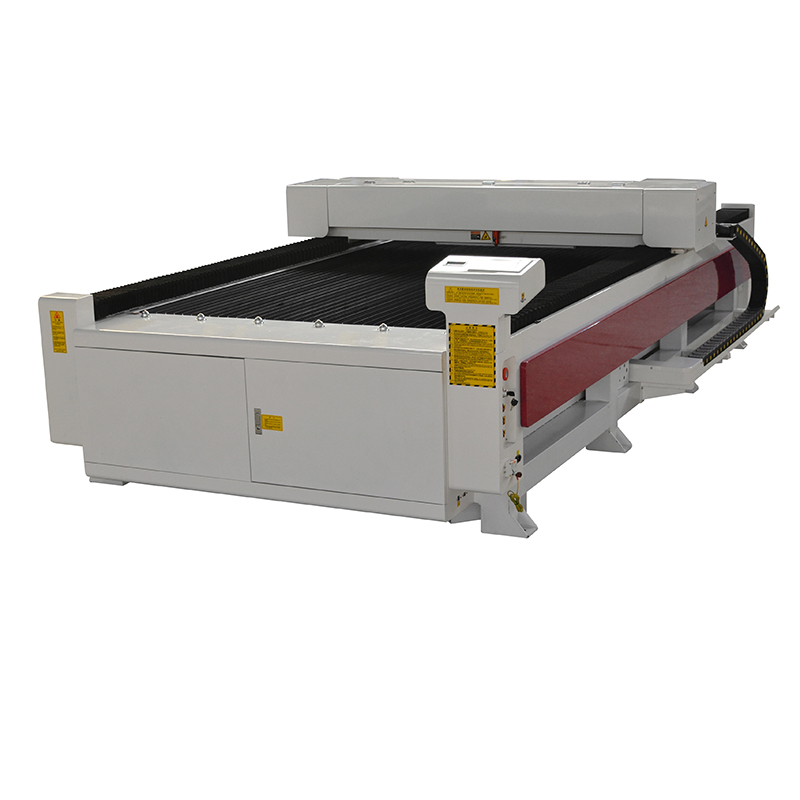

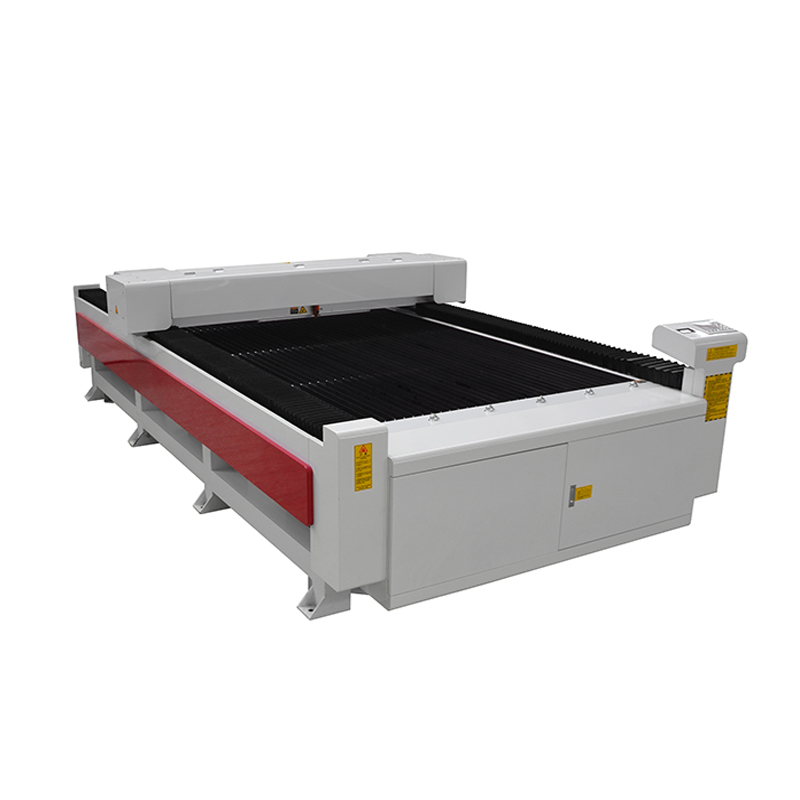

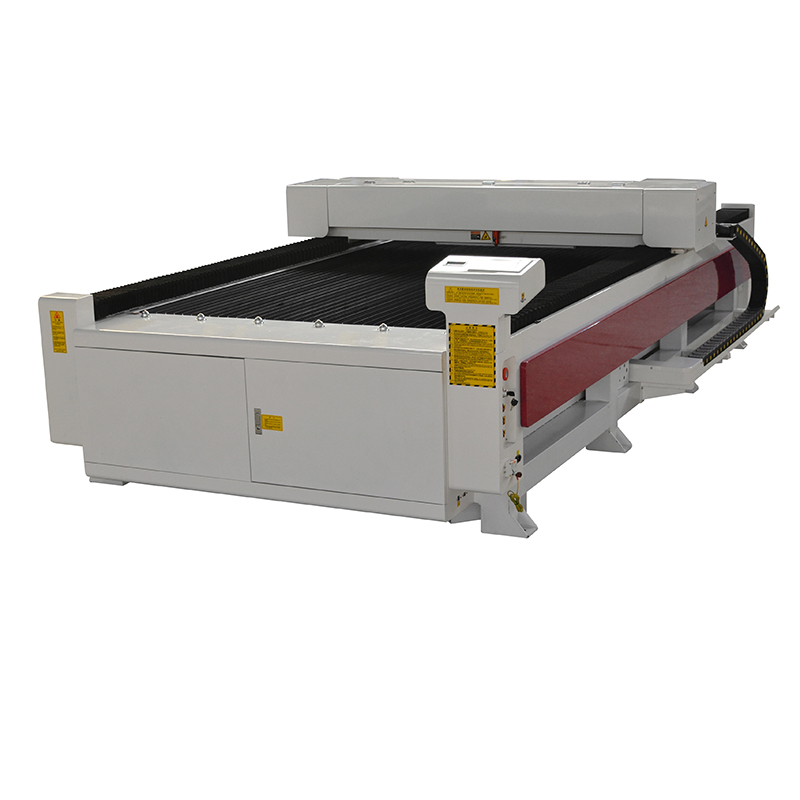

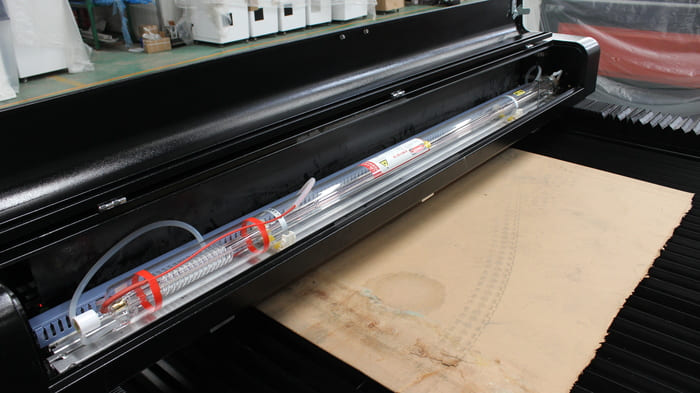

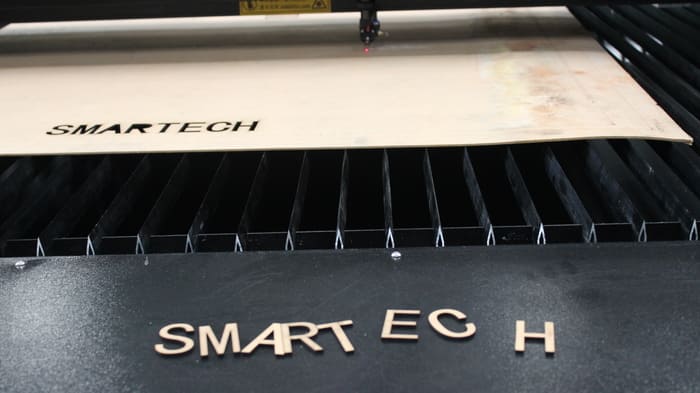

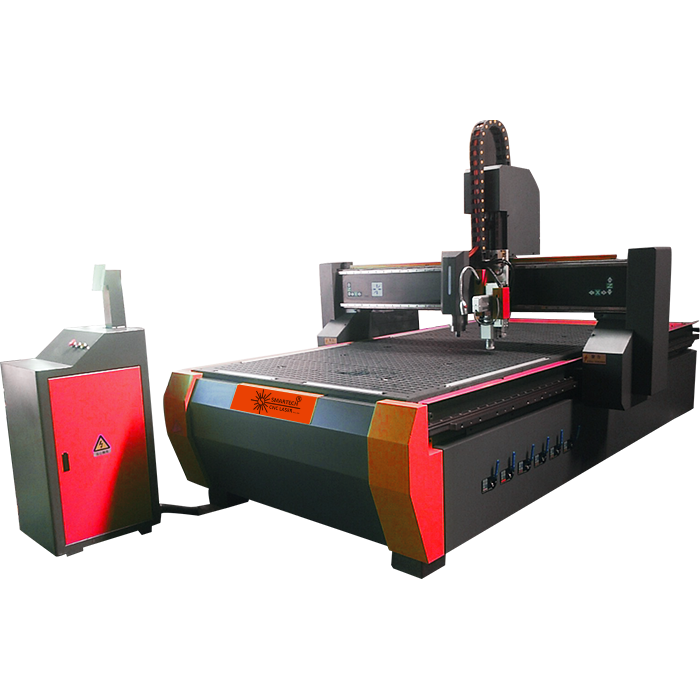

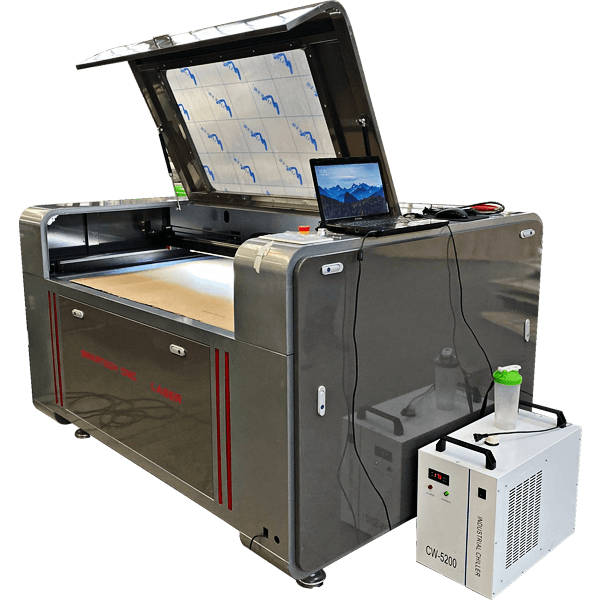

Mix Laser Cutting Machine

SMARTECH

Mix Laser Cutting Machine

3900x2040X1350

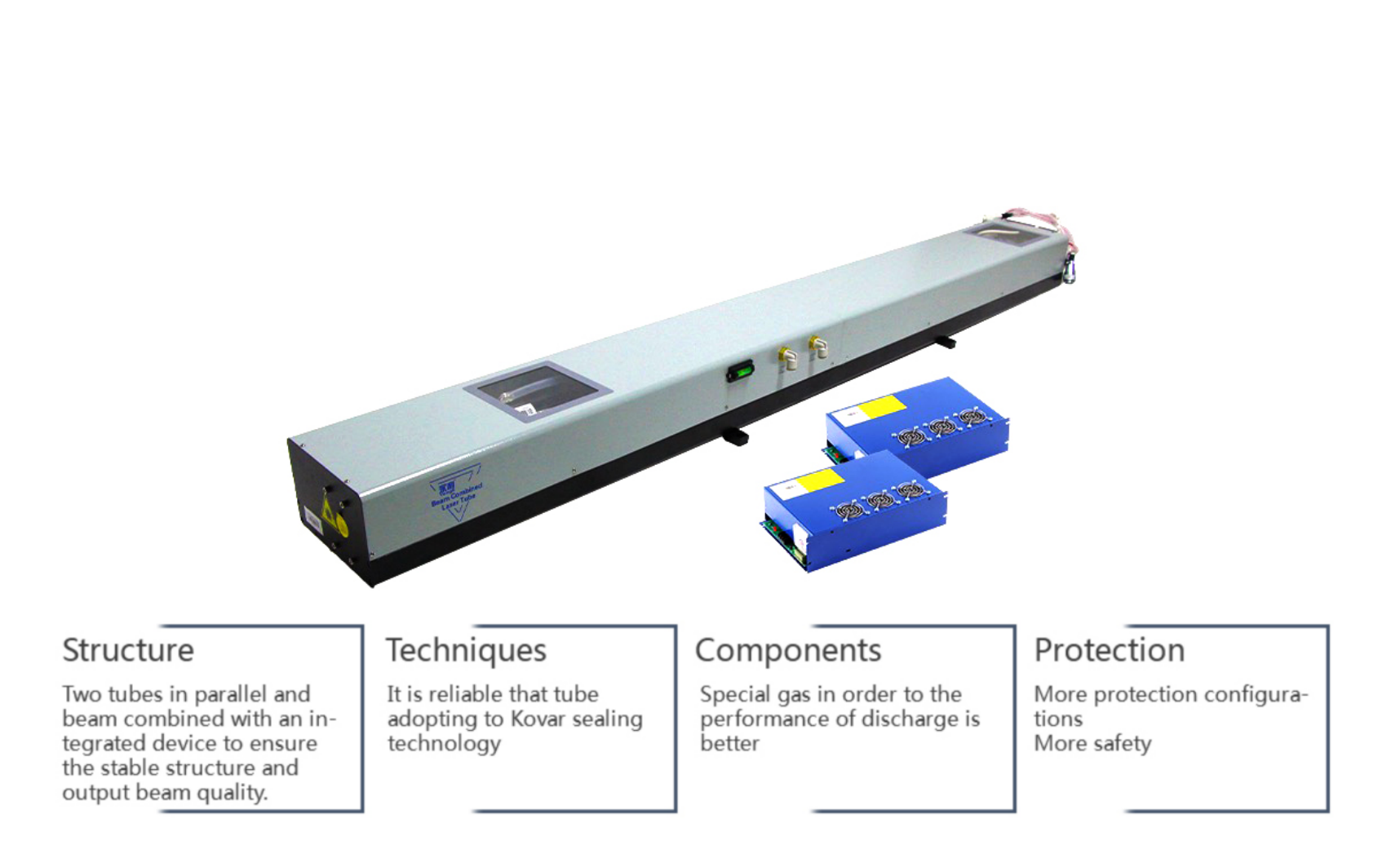

300W

red

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A: Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways? A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China, about 2hours train from Beijing and Shanghai.

-Q Can I arrange sample for cutting test?

A:Yes, always welcome.

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality control system in our production process.

-Q: How to install and run the machine?

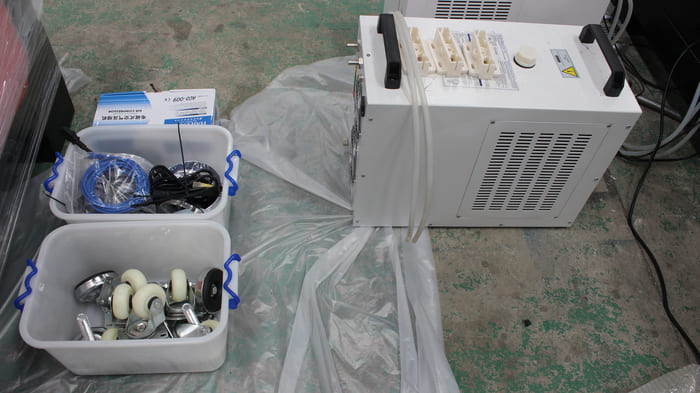

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95% customers can learn by themselves

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A: Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways? A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China, about 2hours train from Beijing and Shanghai.

-Q Can I arrange sample for cutting test?

A:Yes, always welcome.

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95% customers can learn by themselves