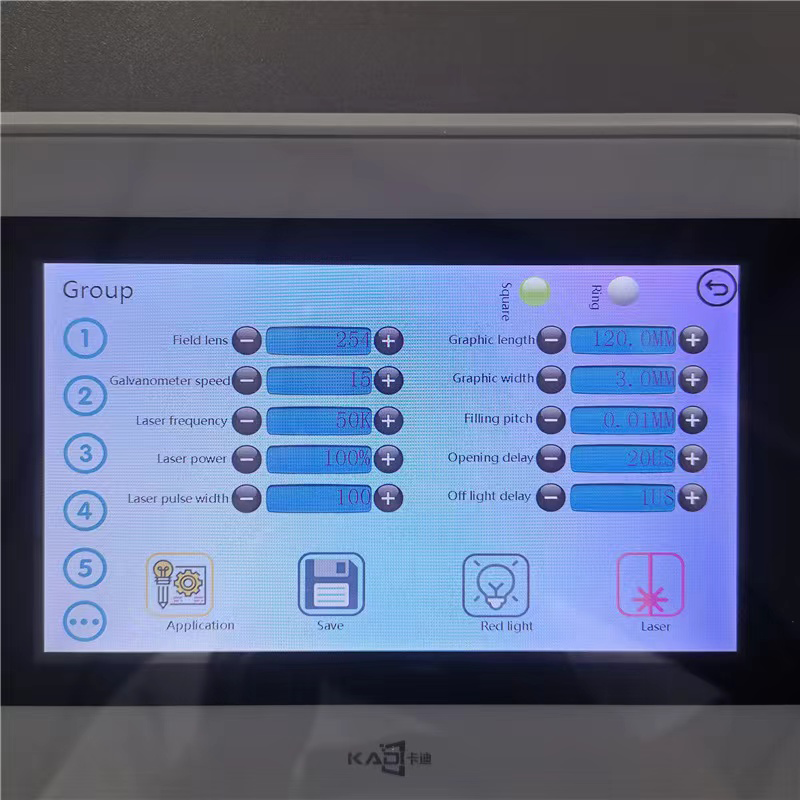

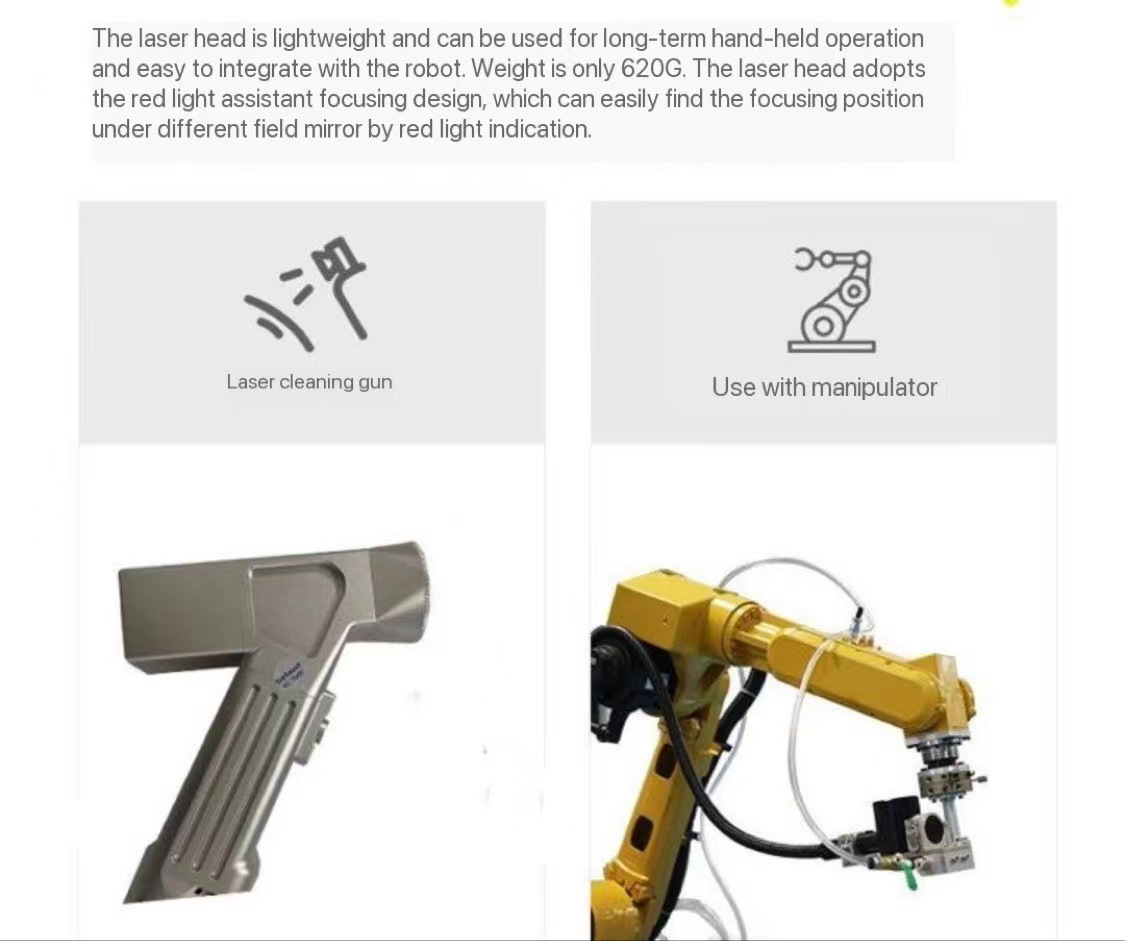

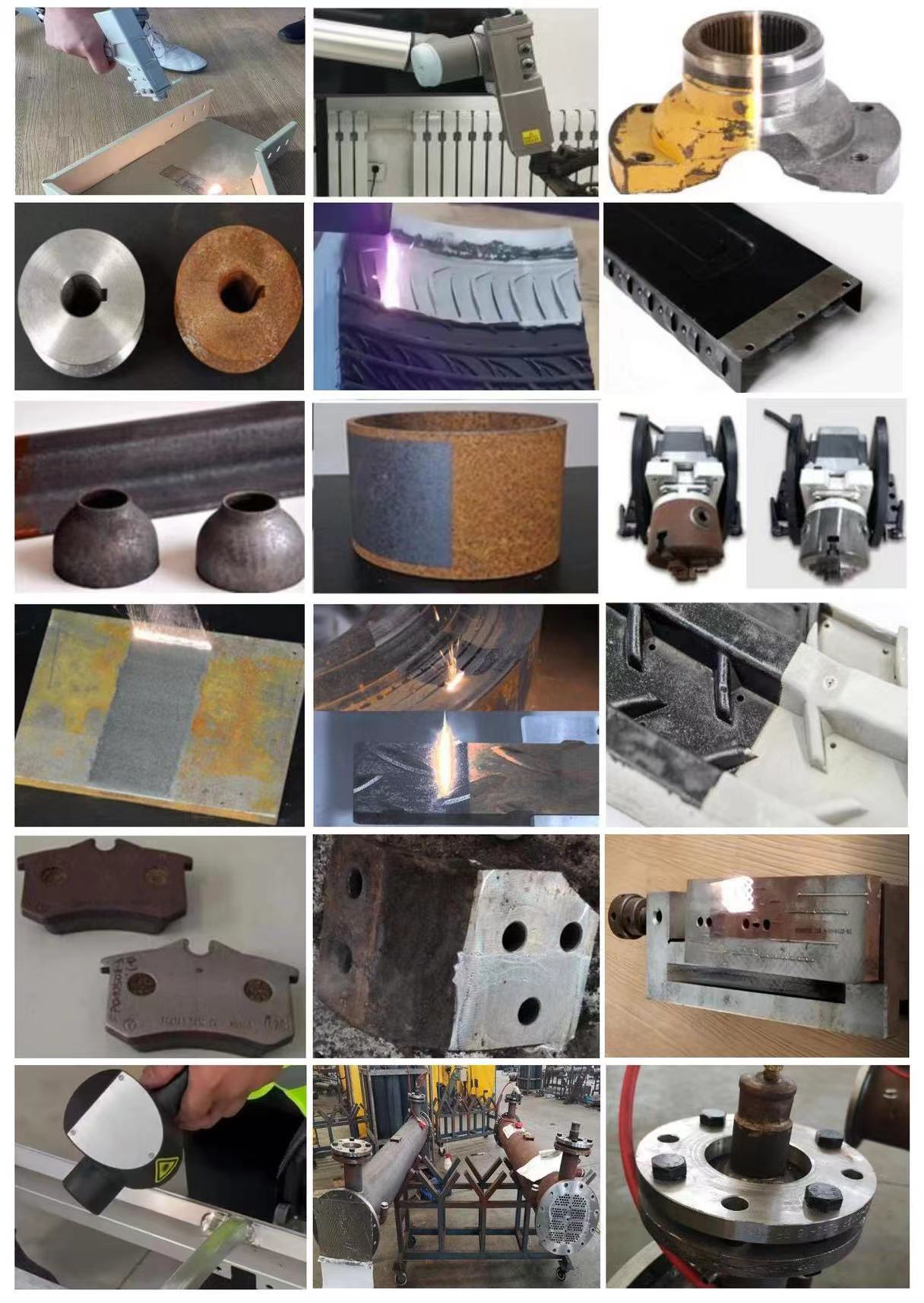

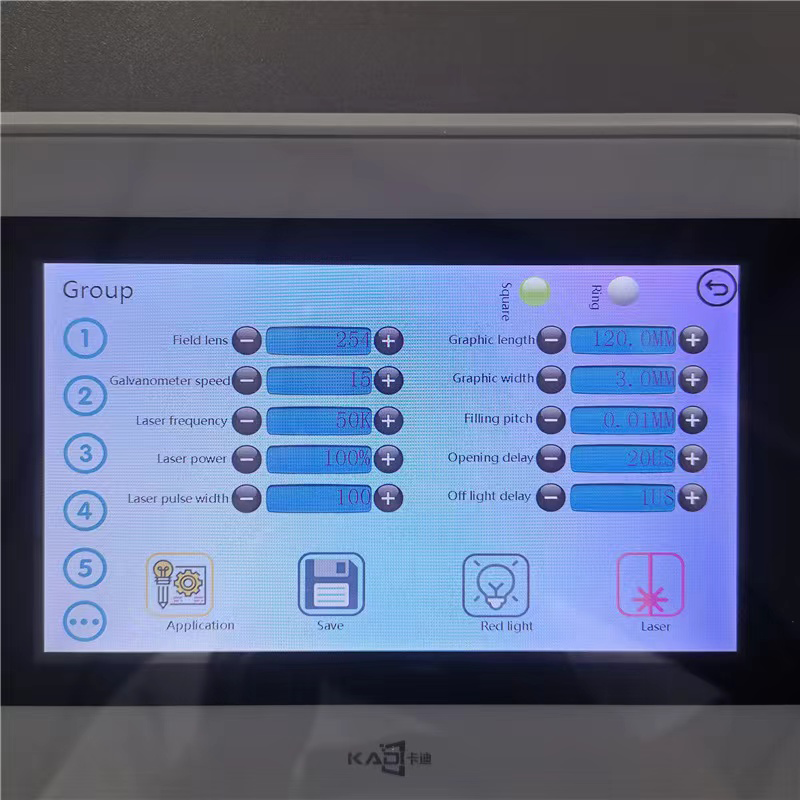

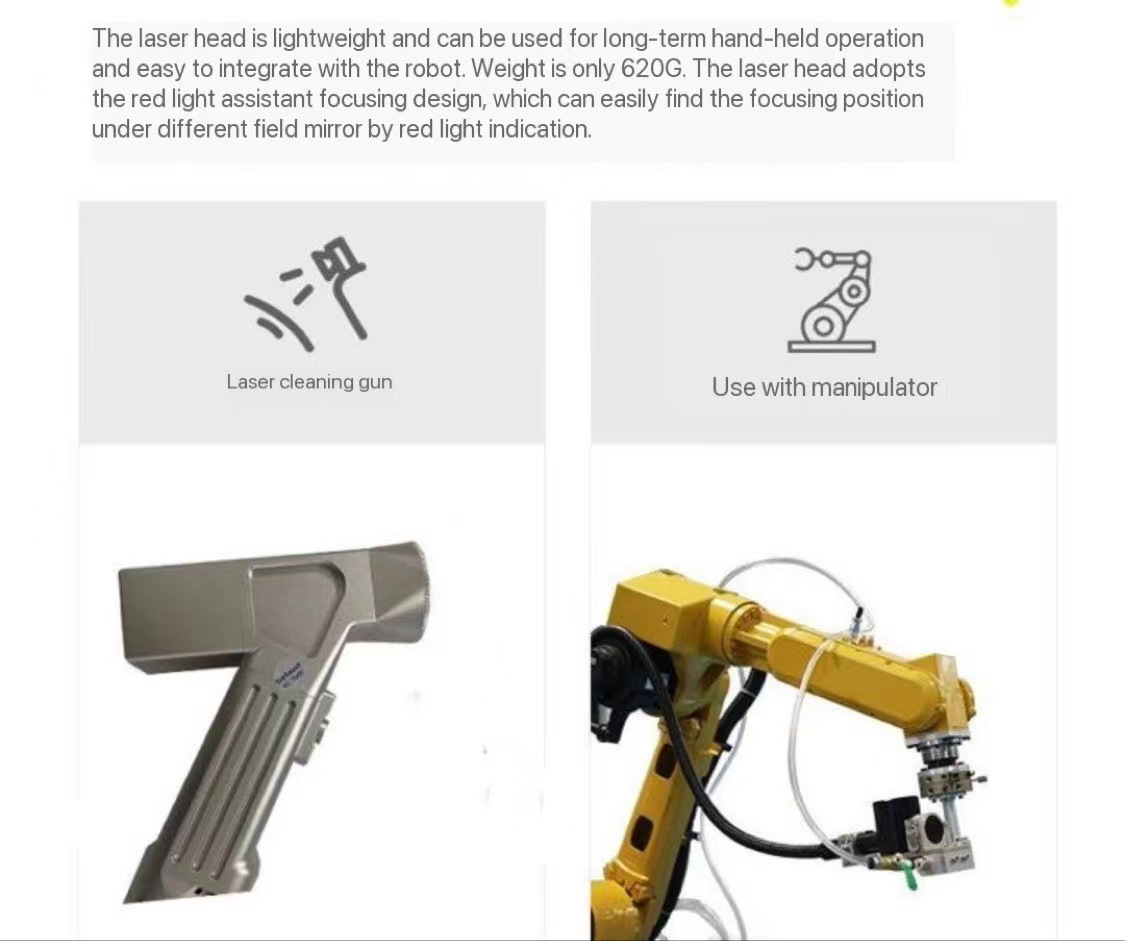

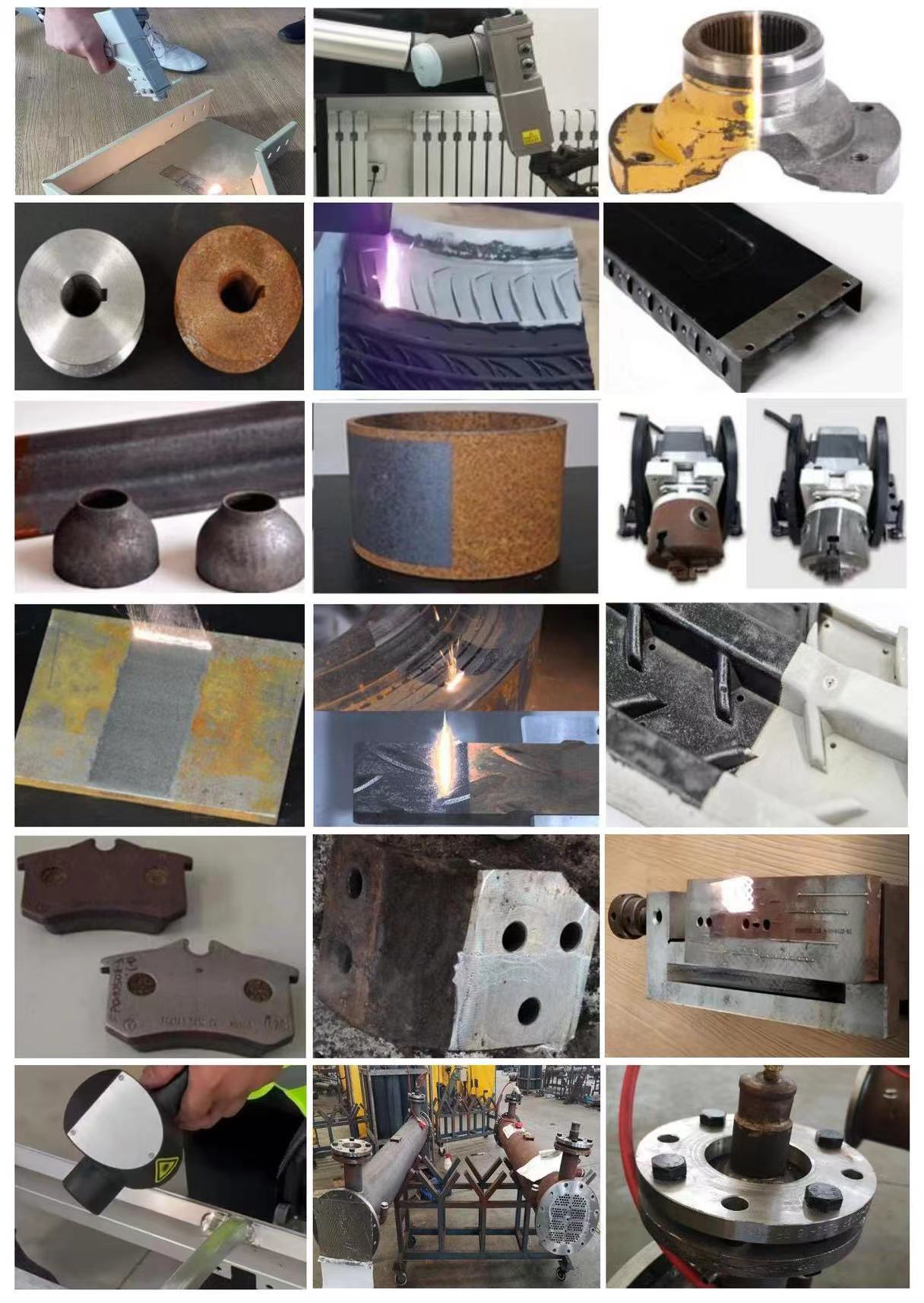

1. Non-contact cleaning 2. With universal wheels, easy to move 3. Adjustable man-machine interface parameters 4. Suitable for hand-held cleaning operations with robotic hands 5. Can be used for designated location/size cleaning 6. Will not cause damage to any metal surface 7. Water cooling system 8. High efficiency, no consumables, safety and environmental protection. 9. Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid solid strong impact cleaning, and high-frequency ultrasonic cleaning, SMARTECH laser cleaning machines have obvious advantages. Wide range of applications: Laser cleaning can remove various types of contaminants on the surface of various materials to achieve a cleanliness that cannot be achieved by conventional cleaning. It can also selectively clean the contaminants on the surface of the material without damaging the surface of the material. 10. Easy to operate: The SMARTECH laser can be transmitted through optical fiber, cooperate with the robot to realize long-distance operation, and can clean complex structures that are not easily reached by traditional methods. This feature also makes the safety of operators more secure in some dangerous places. 11. High cleaning efficiency: The cleaning efficiency of the SMARTECH laser cleaning machine is very high, and the laser cleaning is non-grinding, non-contact, and non-thermal. It will not produce mechanical force on the object to be cleaned, and will not cause damage to the surface of the object to be cleaned. Moreover, it does not need to use any chemicals and cleaning fluid when cleaning, and it will not pollute the environment. Green and environmental protection: No chemical agents and cleaning fluids are required. The cleaned waste is basically solid powder, small in size, easy to store, recyclable, no photochemical reaction, and no pollution. 12. Low cost: The initial investment of the SMARTECH laser cleaning system is relatively high, but it can be used stably for a long time, with a service life of up to 10 years, low operating cost, fast speed, high efficiency, time saving, and a return on investment soon. In the long run, The cost is lower than traditional cleaning methods.