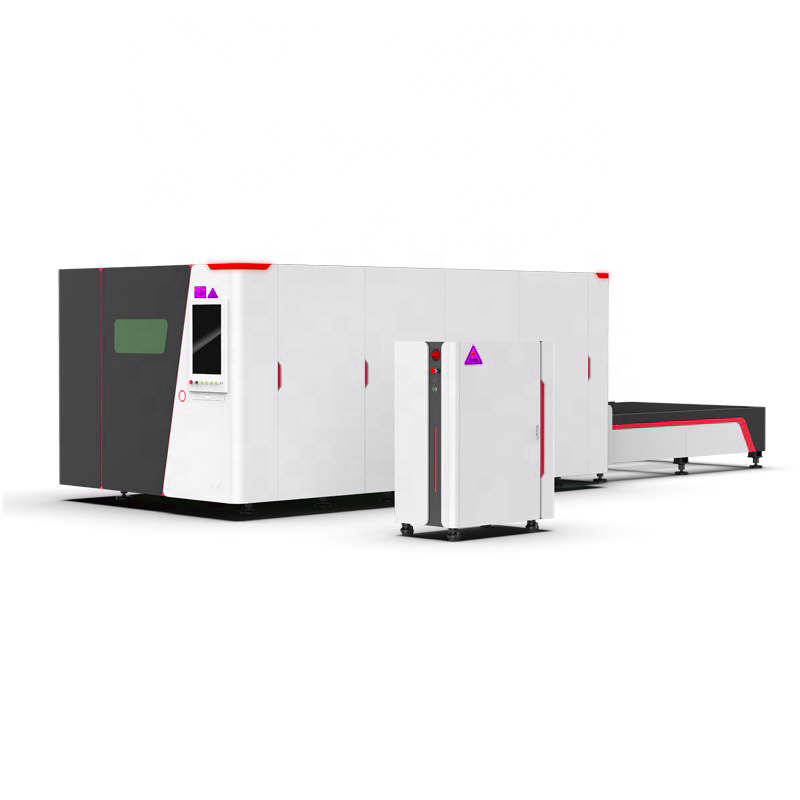

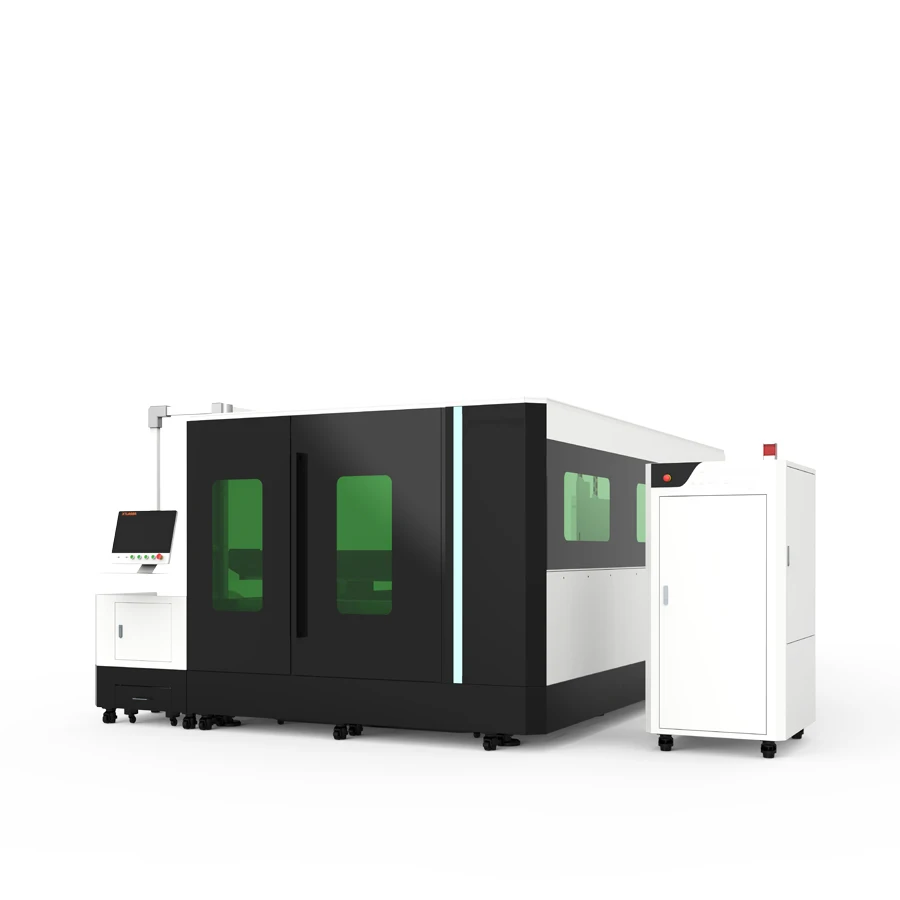

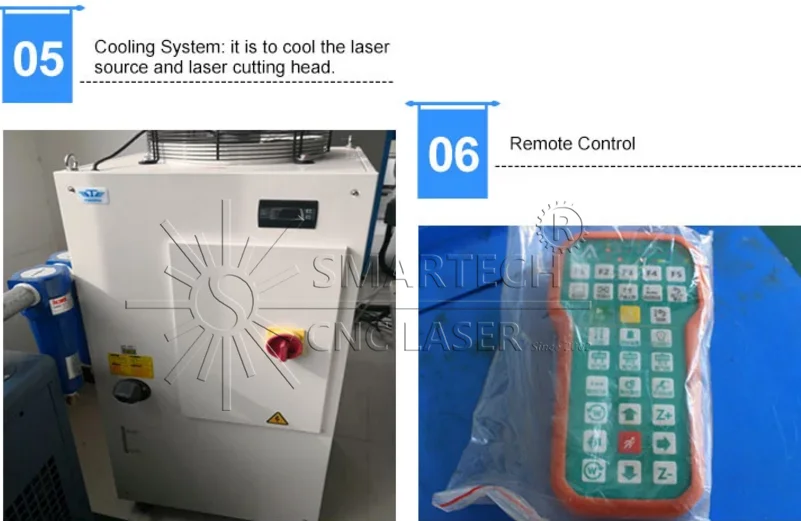

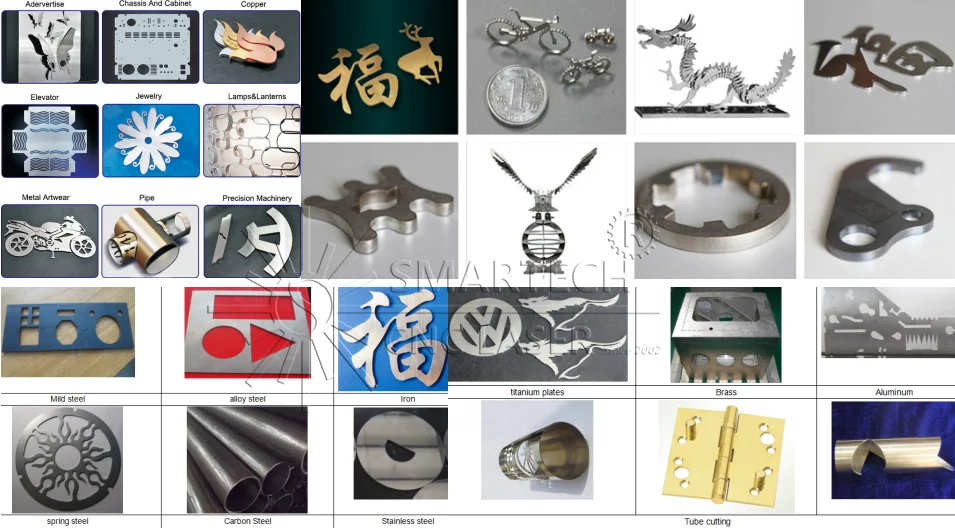

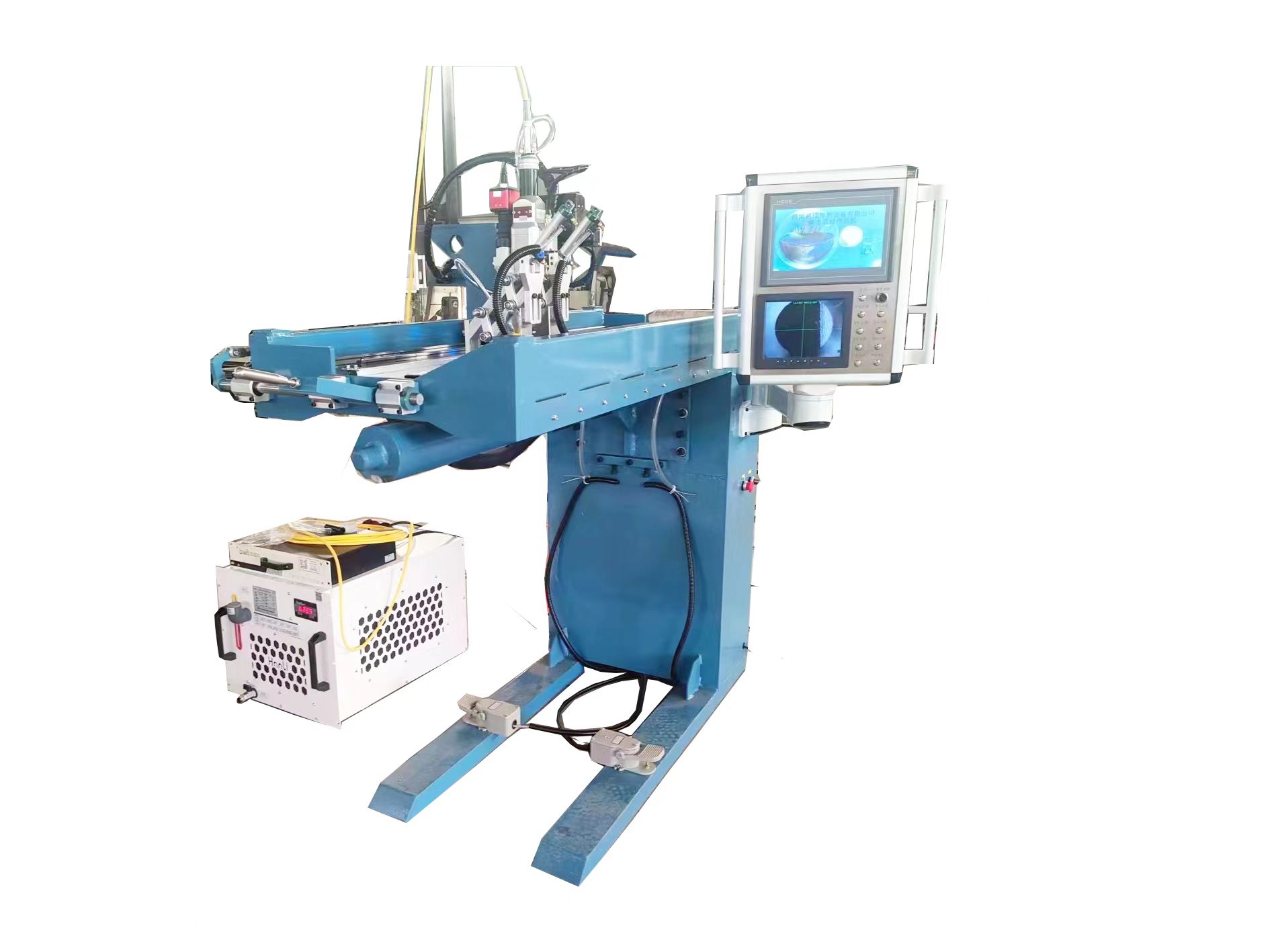

1). Fiber laser cutting machine for metal sheet cutting. Suitable for cutting stainless steel, carbon steel, galvanized, or other non ferrous metals, like: copper and Aluminum. 2). Heavy duty cast iron machine frame, after over 1000 degree thermal treatment and vibration aging, will not deformation in long term use, and keep stable and high precision. Strong shock absorption and wear resistance.Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using. 3). Machine with Aluminium cast beam, aerospace standard inside struction, with the highest strength among other gantry and light weight, improve machine speed, crosion resistance, anti-oxidation, durable in long term use.Molded and framed by integral steel mold and die-casting technology, light crossbeam enables equipment a high operation speed, improving processing efficiency and processing quality. 4). High quality cutting effect, no need for second process, allow cut with complicated drawings. 5). For metal component, precision parts processing, steel processing industry, machinery manufacturing industry, automobile manufacturing industry, central air conditioner, advertising light and panel, metal art craft and so on.Suitable for high precision metal cutting. 6). Easy optional, can edit drawings on site, other language version controller can be customize. 7.)Professional laser optical system and imported lens, stable and reliable; 8.)Efficient and stable programming and control system, simple and easy to learn and humanization, compatible with a variety of CAD drawing formats, intelligent arrangement cost saving, automatic cutting path matching saves processing time; 9.)Less energy consumption and low cost; high stability, simple and convenient maintenance and low maintenance cost; 10.).No mold, flexible processing, can meet the processing requirements of various special-shaped work piece; 11.)High cutting efficiency, high cutting quality, no noise, and the Cutting speed is up to 30m/min when cutting sheet; Seam deformation is small, the appearance is smooth, beautiful; 12.)High precision servo motor, guide rail, gear rack, ensure the machining efficiency and machining accuracy, the stability and reliability of the equipment is greatly improved. 13.)Machine tool, crossbeam and worktable adopt integral welding structure,in accordance with the standard large machine, to stress annealing after precision finishing and then for vibration aging treatment, it can completely eliminate the welding stress and processing stress, keep high-strength, high precision, and also keep the 20 years of normal operation without deformation.