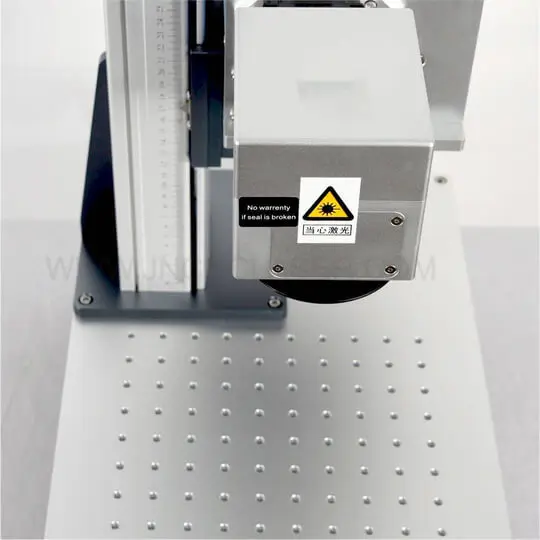

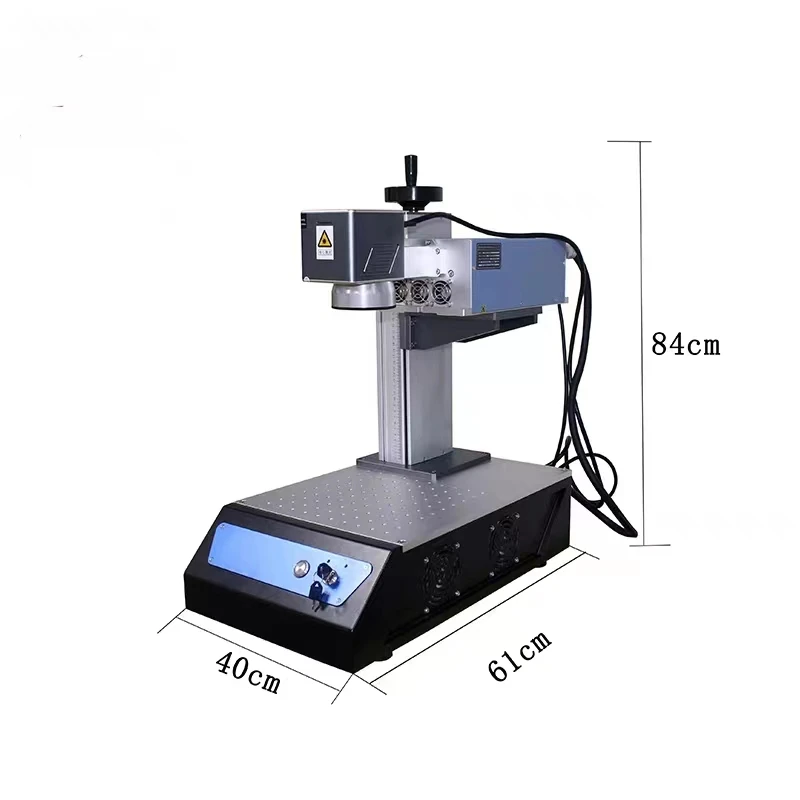

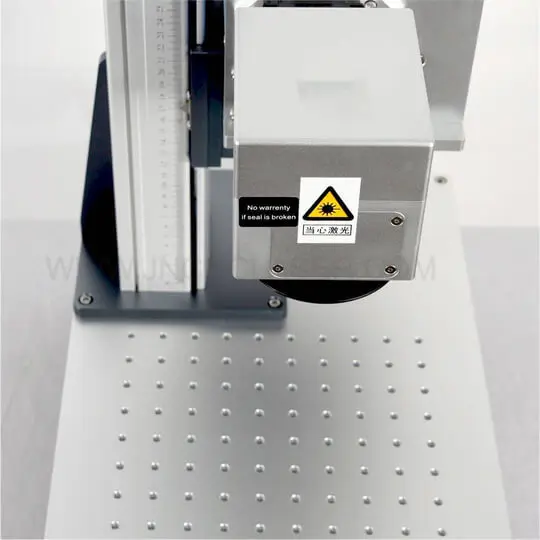

Product Introduction:Laser UV laser is cold ligh source. UV laser with short wavelength,focus,smaller spot,belongs to coldprocess with a little heat affecting,good beam quality, it can achieve hyperfine marking.Most materials can absorb ultraviole laser,it is widely applied on industrials; with very little heat affecting area, it won't have heat effect,there is no burning problem,pollution-free,non-toxic,high marking speed,high efficiency,the machine performance is stable,low power consumption.

Product Application:(1) It is widely used in electronic components, battery chargers, electric wire, computer accessories, mobile phone accessories (mobile phone screen, LCD screen) and communication products. (2) Automobile and motorcycle spare parts, auto glass, instrument appliance, optical device, aerospace, military industry products, hardware machinery, tools, measuring tools, cutting tools, sanitary ware. (3) Pharmaceutical, food, beverage and cosmetics industry. (4) Glass, crystal products, arts and crafts of surface and internal thin film etching, ceramic cutting or engraving, clocks and watches and glasses. (5) It can be marked on polymer material, majority of the metal and non-metallic materials for surface processing and coating film processing, pervious to light polymer materials, plastic, etc,. Main Features: Adopting doubling technique of intravenous frequency has greatly improve the stability of laser.Design on laser cavity adopts a series of optimization method, so as to ensure the beam quality as the fundamental mode. (2) The machine takes 355nm pumped purple light laser device as the light source. Narrower pulse width and smaller heat affection contribute to generate peak power. The higher the peak power is, the wider the adapting range of materials is. This implement perfect printing in some relatively hard material. (3) Higher pulse stability, namely better pulse consistency of laser produces the same carving effect, so it’s very suitable for precision marking. Higher pulse repetition frequency meets the need of quick marking and high production efficiency. (4) High efficiency of the photoelectric conversion and long service life. (5) Automatic in a rotary table (optional item), convenient feeding, fast speed, high efficiency. (6) The mark is of environmental protection, comply with RoHS standard. (7) It can support logos and graphs designed in DXF format from Auto-CAD, PLT, BMF, AI, JPG, etc. (8) It can mark date, bar code and two-dimension code automatically. (9) Superior performance, good stability, high conversion rate and low energy consumption. (10)Faster and more efficient marking efficiency.