| Availability: | |

|---|---|

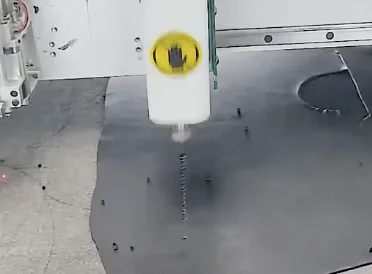

CNC Oscillating Knife Machine For Leather/bags/garment/fabric/pvc/carpet/cloth/kt board

SMARTECH

New Product 2021

3250*2150*1350MM/3050×2100×1350mm

9.0KW

as your preference

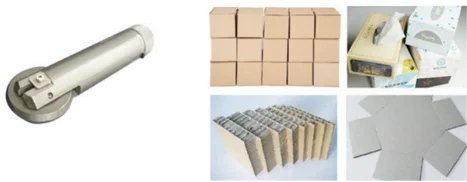

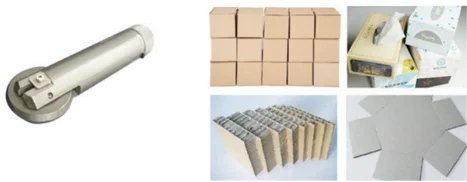

leather, microfiber, pvc, soft glass, silicone and other non-breathable or flexible materials with poor air permeability; you can choose different angles of cutting blades, such as 35°, 26°, 16°, etc. to cut different thicknesses material.

Model | SO- 1625 Oscillating knife Machine |

Working area | 1600*2500mm |

Knife tools include | Swiss imported Digital Round Knife,CCD Camera |

Working table | Auto feeding working table For soft materials,such as leather,fabric etc |

Control system | LED Touching screen |

Cutting speed | 0-1,500mm/s(according to different cutting materials) |

Cutting thickness | ≤65mm (support customized demands) |

Cutting accuracy | ≤0.1mm |

Translational velocity | 800-1200mm/s |

Drive system | Yaskawa servo motor and driver |

Transmission system | Imported(Digital servo motor, linear guide, synchronous belt, Helical Gear) |

Material fixed way | Vacuum suction system |

Vacuum pump power | 9.0KW |

Model | SO- 1625 Oscillating knife Machine |

Graphic format supported | PLT, DXF, AI, etc. |

Connection | Network port/WIFI/USB |

Instruction system | HP-GL compatible format |

Compatible | CORELDRAW, PHOTOSHOP, AUTOCAD, TAJIMA, etc. |

Safety device | Infrared sensors and emergency stop devices double protection.More responsive, safe and reliable. |

Working voltage | AC 220V±10%, 50Hz/60Hz |

Package | Wooden case |

Machine size | 3000×2070×1350mm(SO 1625) |

Packing Size | 3100x2200x1700mm |

Net weight | 1500KGS |

Gross weight | 1600KGS |

Features

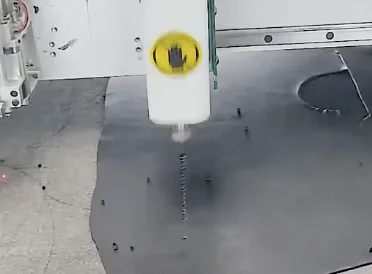

01.High Speed:Only need 80 seconds to finish one set of car foot mat, only need 6 minutes to finish one set of car cushion

mattress. 02.Low Cost:The digital fabric cutting machine machine can do design, cutting instead of manual design and cutting, save

labor, and material wastage cost. 03.High efficiency:No need of any die mold, or die mold cutting machine, this digital cutting

machine can press mark, cutting and molding on soft materials such as fabric, leather, textile, carton and more, saving much labor

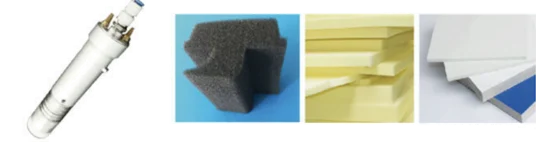

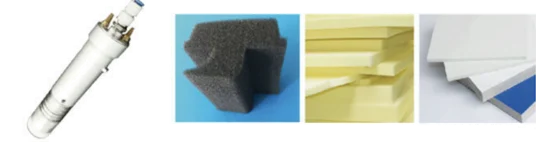

and cost. 04. Wide Applications :This digital leather cutting machine can cut textile, fabric, leather, paper, carton, PU, fiber,

PVC foot mat, EVA, XPE, fiberglass, composite cladding, sponge cladding, sponge+drape+composite leather, plastic board and other

soft materials. 05. High Performance:The flatbed digital cutter adopts Taiwan TBI ball screw or high precision rack pinion with

low noise, accurate transmission, long service life, and high precision. 06.More Safe:The anti-collision and the built-in

auto-sensing devices ensure the security of oscillating knife

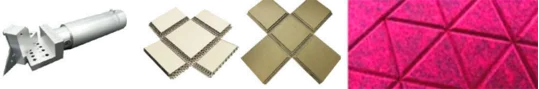

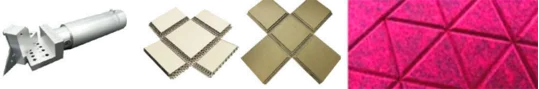

Machine heads

leather, microfiber, pvc, soft glass, silicone and other non-breathable or flexible materials with poor air permeability; you can choose different angles of cutting blades, such as 35°, 26°, 16°, etc. to cut different thicknesses material.

Model | SO- 1625 Oscillating knife Machine |

Working area | 1600*2500mm |

Knife tools include | Swiss imported Digital Round Knife,CCD Camera |

Working table | Auto feeding working table For soft materials,such as leather,fabric etc |

Control system | LED Touching screen |

Cutting speed | 0-1,500mm/s(according to different cutting materials) |

Cutting thickness | ≤65mm (support customized demands) |

Cutting accuracy | ≤0.1mm |

Translational velocity | 800-1200mm/s |

Drive system | Yaskawa servo motor and driver |

Transmission system | Imported(Digital servo motor, linear guide, synchronous belt, Helical Gear) |

Material fixed way | Vacuum suction system |

Vacuum pump power | 9.0KW |

Model | SO- 1625 Oscillating knife Machine |

Graphic format supported | PLT, DXF, AI, etc. |

Connection | Network port/WIFI/USB |

Instruction system | HP-GL compatible format |

Compatible | CORELDRAW, PHOTOSHOP, AUTOCAD, TAJIMA, etc. |

Safety device | Infrared sensors and emergency stop devices double protection.More responsive, safe and reliable. |

Working voltage | AC 220V±10%, 50Hz/60Hz |

Package | Wooden case |

Machine size | 3000×2070×1350mm(SO 1625) |

Packing Size | 3100x2200x1700mm |

Net weight | 1500KGS |

Gross weight | 1600KGS |

Features

01.High Speed:Only need 80 seconds to finish one set of car foot mat, only need 6 minutes to finish one set of car cushion

mattress. 02.Low Cost:The digital fabric cutting machine machine can do design, cutting instead of manual design and cutting, save

labor, and material wastage cost. 03.High efficiency:No need of any die mold, or die mold cutting machine, this digital cutting

machine can press mark, cutting and molding on soft materials such as fabric, leather, textile, carton and more, saving much labor

and cost. 04. Wide Applications :This digital leather cutting machine can cut textile, fabric, leather, paper, carton, PU, fiber,

PVC foot mat, EVA, XPE, fiberglass, composite cladding, sponge cladding, sponge+drape+composite leather, plastic board and other

soft materials. 05. High Performance:The flatbed digital cutter adopts Taiwan TBI ball screw or high precision rack pinion with

low noise, accurate transmission, long service life, and high precision. 06.More Safe:The anti-collision and the built-in

auto-sensing devices ensure the security of oscillating knife

Machine heads