| Availability: | |

|---|---|

Fiber Laser

SMARTECH

538*411*685mm

100W, 200w, 300w

| project | Traditional cleaning (manual hours) | Laser cleaning (manual time) |

| clean | 1040 | 300 |

| rust removal | 200 | 40 |

| paint removal | 155.5 | 50 |

| Summarize | 1395.5 | 390 |

| in conclusion | Save 1,000 man-hours in a single row | |

| project | Traditional cleaning (manual hours) | Laser cleaning (manual time) |

| clean | 1135 | 300 |

| rust removal | 134 | 30 |

| paint removal | 311.5 | 100 |

| Summarize | 1580.5 | 430 |

| in conclusion | Save 1100 man-hours in a single row | |

Expected savings in four years (in the next four years, xx subway will repair 231 trains and overhaul 134 trains)

time | cost | save | Remark | |||||

traditional outsourcing | Laser cleaning outsourcing | The use of laser cleaning can greatly reduce labor costs, and the four-year "self-cleaning business" is expected to save 4620,000 USD | ||||||

manpower | Consumables | manpower | electricity bill | depreciation | maintain | |||

2019 | 697.156 | 118 | 192.4 | 1.5 | 177 | 0 | 444.256 | |

2020 | 1589.09 | 264 | 436.8 | 1.5 | 177 | 0 | 1237.79 | |

2021 | 1540.38 | 268 | 427.68 | 1.5 | 177 | 0 | 1202.2 | |

2022 | 558.2 | 100 | 156 | 1.5 | 177 | 17.7 | 306 | |

Total | 4384.82 | 750 | 1212.88 | 6 | 708 | 17.7 | 3190.24 | |

| Technical Parameter | 200W | 300W |

| Laser Type | Pulse fiber laser | Pulse fiber laser |

| Laser power life span | 100000 Hours | 100000 Hours |

| Power range (%) | 10-100(adjustment ) | 10-100(adjustment ) |

| Repeat frequency (KHz) | 20-200(adjustment) | 20-400(adjustment) |

| Cooling mode | Air/Optional water | Air/Optional water |

| Laser switch-off time | 2 μs | 2 μs |

| Small Step Response Time | ≤0.3ms | ≤0.3ms |

| Max output power (W) | 200 | 300 |

| Output power instability(%) | ≤5 | ≤5 |

| Optical fiber length | 5m | 5m |

| Laser safety classification | 3/5 | 3 |

| Weight | 69 KG | 79 Kg |

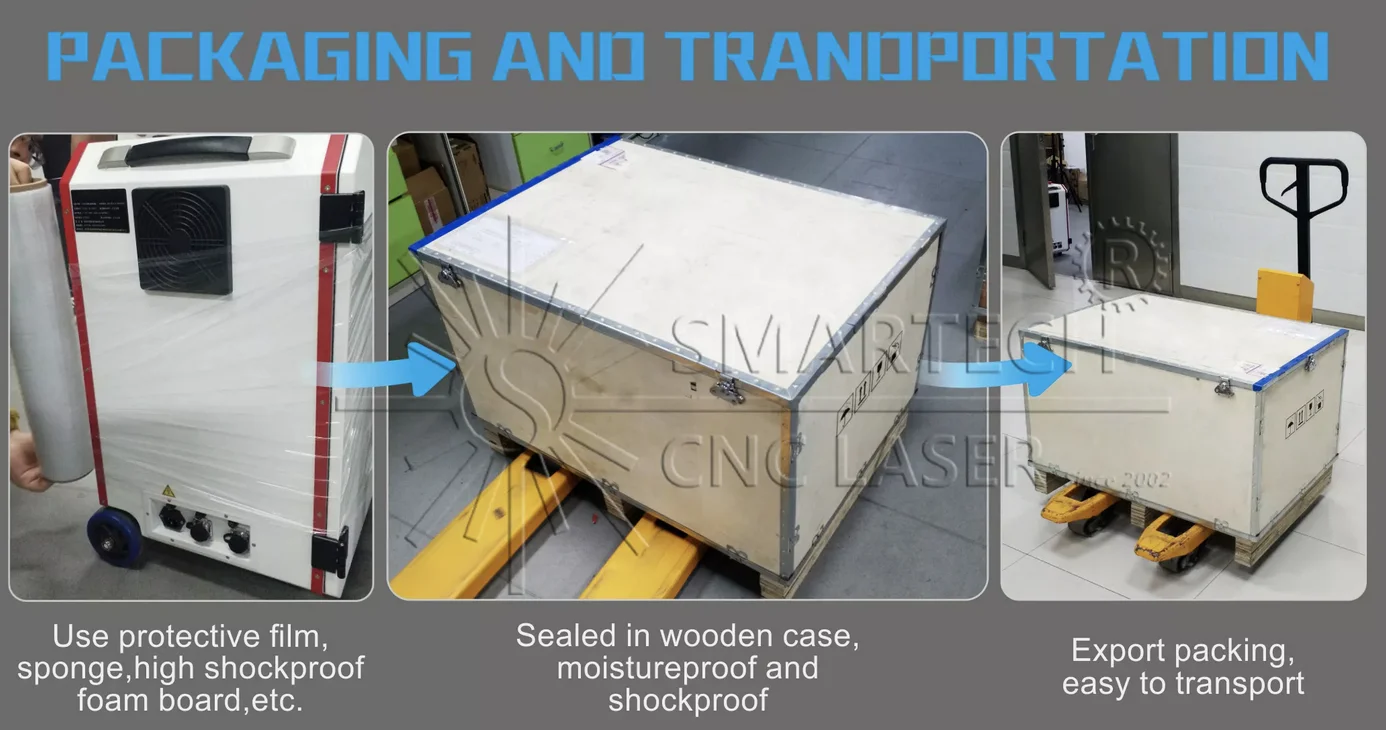

| Size | 97×107×77 cm | 97×107×77 cm |

| Package size | 1088×110×80 cm | 1088×110×80 cm |

| Voltage | 110/220/380V | 110/220/380V |

·Multilangual languages for options-Russian,English,Spanish,Turkish,Arabic etc

Laser Source

Ship industry

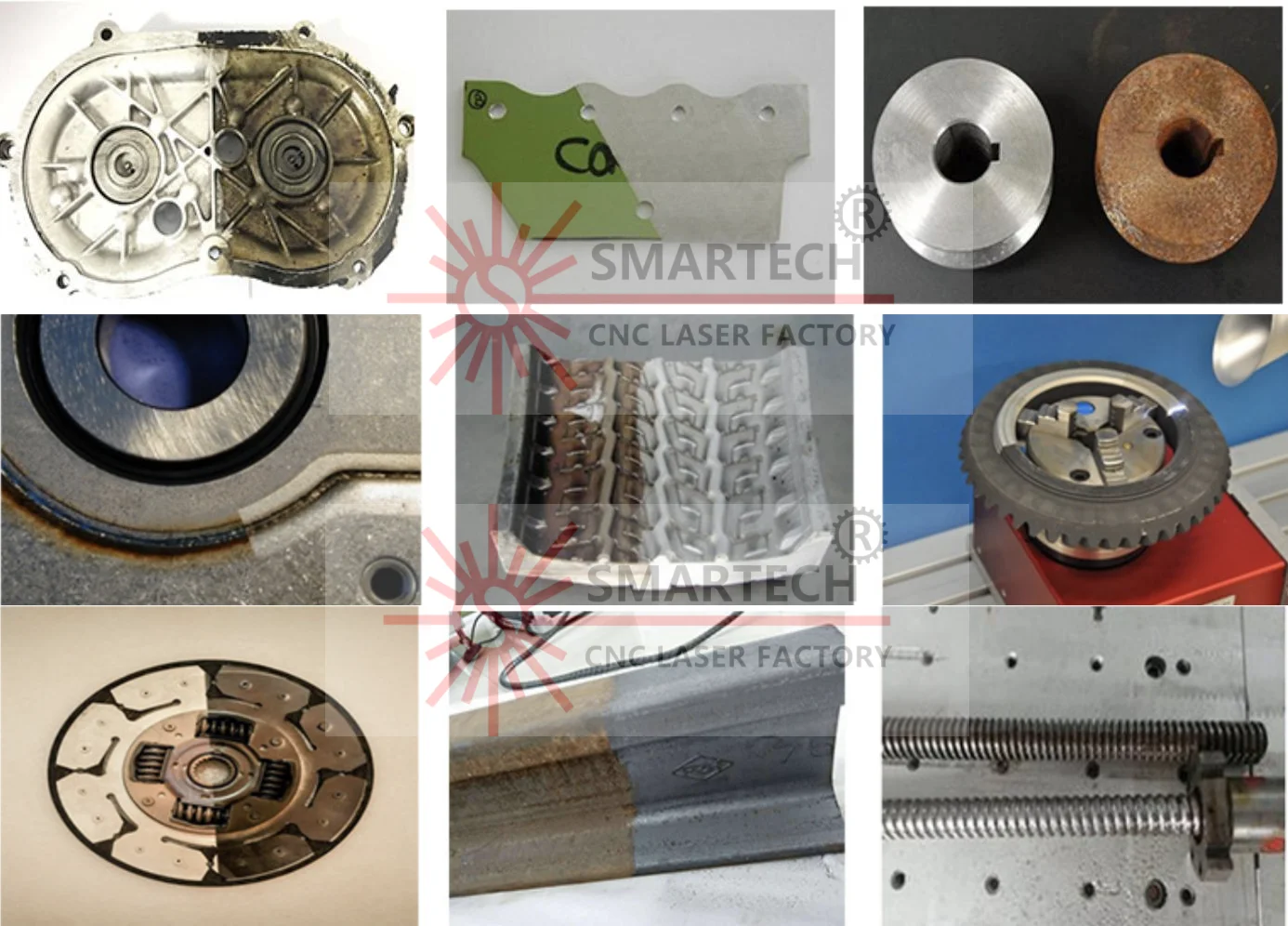

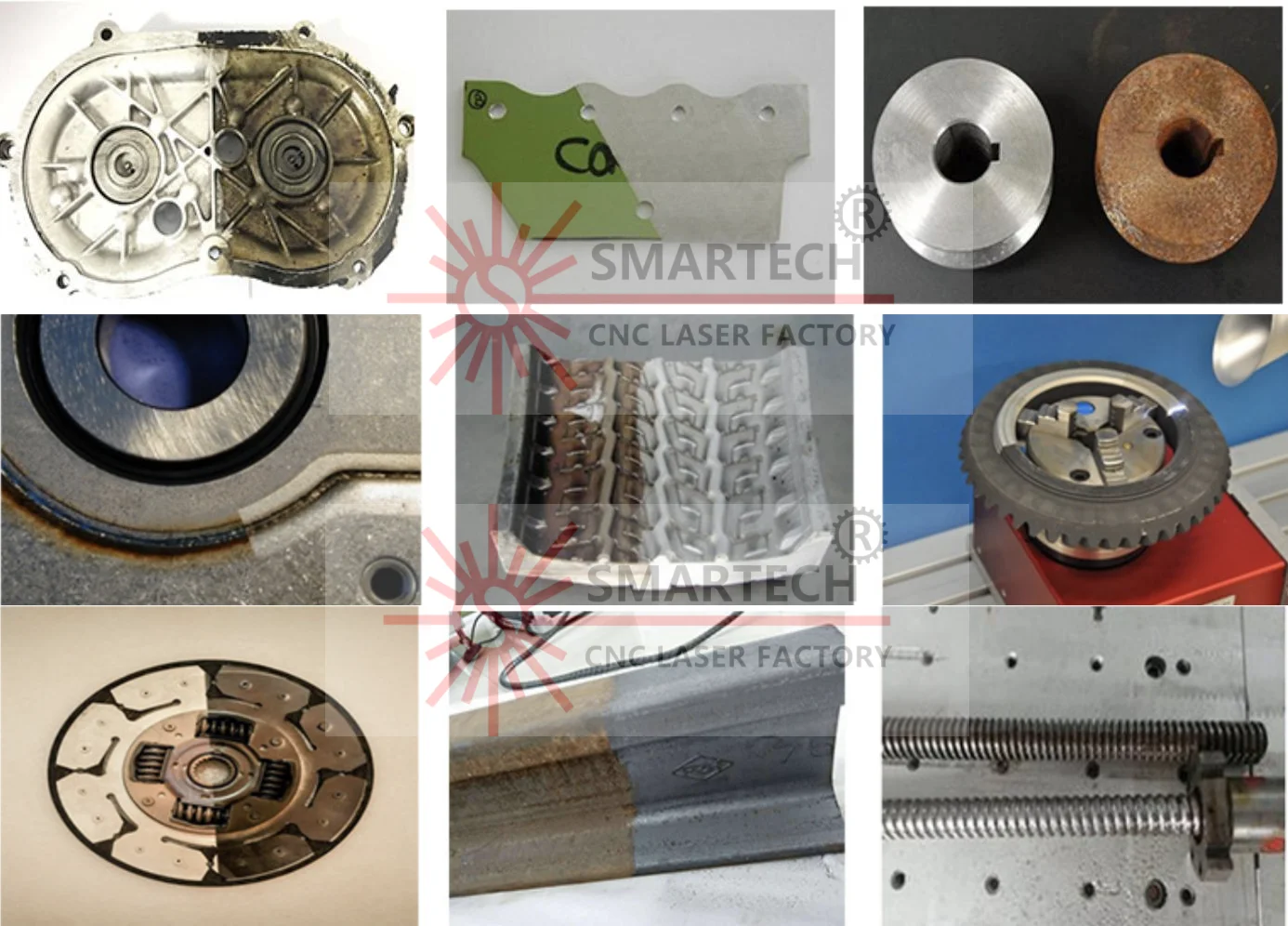

In shipbuilding and repair, cleaning is an essential process. Compared with traditional manual scrubbing, mechanical grinding, chemical cleaning and sandblasting, laser cleaning has the characteristics of energy saving and environmental protection, no consumables, high quality surface treatment, and easy automation control. , which is in line with the national policy of saving resources and protecting the environment, and is more in line with the requirements of China's green and intelligent shipbuilding.

Rail Transit Industry

In order to ensure the safe and stable operation of the railway, the train needs to be overhauled on a regular basis. The main processes include cleaning of its components, flaw detection, and painting of the overall surface. Traditional manual scrubbing, mechanical grinding, chemical cleaning and sandblasting operations face problems such as high pollution, high consumables, low efficiency, and uncontrollable quality

Aerospace Industry

The traditional method is to use chemical paint strippers, water picks, dry medium sandblasting and manual sanding to remove paint and rust. In recent years, laser paint removal systems have achieved great success in the US Air Force base. F-16 The paint time was shortened from 7 days to 3 days, and the paint removal time of C-130 was shortened from 10 days to 5 days. Huize Laser is dedicated to removing paint from aircraft structures with lasers, as well as aircraft surface cleaning.

Oil pipeline industry

Laser cleaning with no pollution, no consumables, and faster speed has also begun to replace the traditional manual and chemical cleaning of oil pipelines. At the same time, the roughening effect brought by the laser greatly simplifies the operation process and has gradually become the future development direction of the industry.

| project | Traditional cleaning (manual hours) | Laser cleaning (manual time) |

| clean | 1040 | 300 |

| rust removal | 200 | 40 |

| paint removal | 155.5 | 50 |

| Summarize | 1395.5 | 390 |

| in conclusion | Save 1,000 man-hours in a single row | |

| project | Traditional cleaning (manual hours) | Laser cleaning (manual time) |

| clean | 1135 | 300 |

| rust removal | 134 | 30 |

| paint removal | 311.5 | 100 |

| Summarize | 1580.5 | 430 |

| in conclusion | Save 1100 man-hours in a single row | |

Expected savings in four years (in the next four years, xx subway will repair 231 trains and overhaul 134 trains)

time | cost | save | Remark | |||||

traditional outsourcing | Laser cleaning outsourcing | The use of laser cleaning can greatly reduce labor costs, and the four-year "self-cleaning business" is expected to save 4620,000 USD | ||||||

manpower | Consumables | manpower | electricity bill | depreciation | maintain | |||

2019 | 697.156 | 118 | 192.4 | 1.5 | 177 | 0 | 444.256 | |

2020 | 1589.09 | 264 | 436.8 | 1.5 | 177 | 0 | 1237.79 | |

2021 | 1540.38 | 268 | 427.68 | 1.5 | 177 | 0 | 1202.2 | |

2022 | 558.2 | 100 | 156 | 1.5 | 177 | 17.7 | 306 | |

Total | 4384.82 | 750 | 1212.88 | 6 | 708 | 17.7 | 3190.24 | |

| Technical Parameter | 200W | 300W |

| Laser Type | Pulse fiber laser | Pulse fiber laser |

| Laser power life span | 100000 Hours | 100000 Hours |

| Power range (%) | 10-100(adjustment ) | 10-100(adjustment ) |

| Repeat frequency (KHz) | 20-200(adjustment) | 20-400(adjustment) |

| Cooling mode | Air/Optional water | Air/Optional water |

| Laser switch-off time | 2 μs | 2 μs |

| Small Step Response Time | ≤0.3ms | ≤0.3ms |

| Max output power (W) | 200 | 300 |

| Output power instability(%) | ≤5 | ≤5 |

| Optical fiber length | 5m | 5m |

| Laser safety classification | 3/5 | 3 |

| Weight | 69 KG | 79 Kg |

| Size | 97×107×77 cm | 97×107×77 cm |

| Package size | 1088×110×80 cm | 1088×110×80 cm |

| Voltage | 110/220/380V | 110/220/380V |

·Multilangual languages for options-Russian,English,Spanish,Turkish,Arabic etc

Laser Source

Ship industry

In shipbuilding and repair, cleaning is an essential process. Compared with traditional manual scrubbing, mechanical grinding, chemical cleaning and sandblasting, laser cleaning has the characteristics of energy saving and environmental protection, no consumables, high quality surface treatment, and easy automation control. , which is in line with the national policy of saving resources and protecting the environment, and is more in line with the requirements of China's green and intelligent shipbuilding.

Rail Transit Industry

In order to ensure the safe and stable operation of the railway, the train needs to be overhauled on a regular basis. The main processes include cleaning of its components, flaw detection, and painting of the overall surface. Traditional manual scrubbing, mechanical grinding, chemical cleaning and sandblasting operations face problems such as high pollution, high consumables, low efficiency, and uncontrollable quality

Aerospace Industry

The traditional method is to use chemical paint strippers, water picks, dry medium sandblasting and manual sanding to remove paint and rust. In recent years, laser paint removal systems have achieved great success in the US Air Force base. F-16 The paint time was shortened from 7 days to 3 days, and the paint removal time of C-130 was shortened from 10 days to 5 days. Huize Laser is dedicated to removing paint from aircraft structures with lasers, as well as aircraft surface cleaning.

Oil pipeline industry

Laser cleaning with no pollution, no consumables, and faster speed has also begun to replace the traditional manual and chemical cleaning of oil pipelines. At the same time, the roughening effect brought by the laser greatly simplifies the operation process and has gradually become the future development direction of the industry.