| Availability: | |

|---|---|

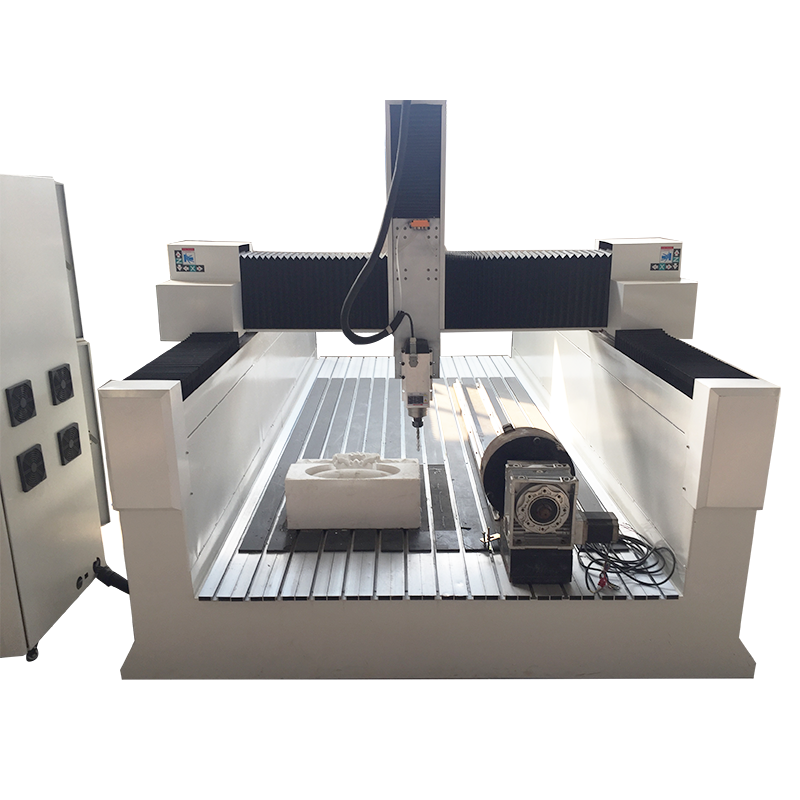

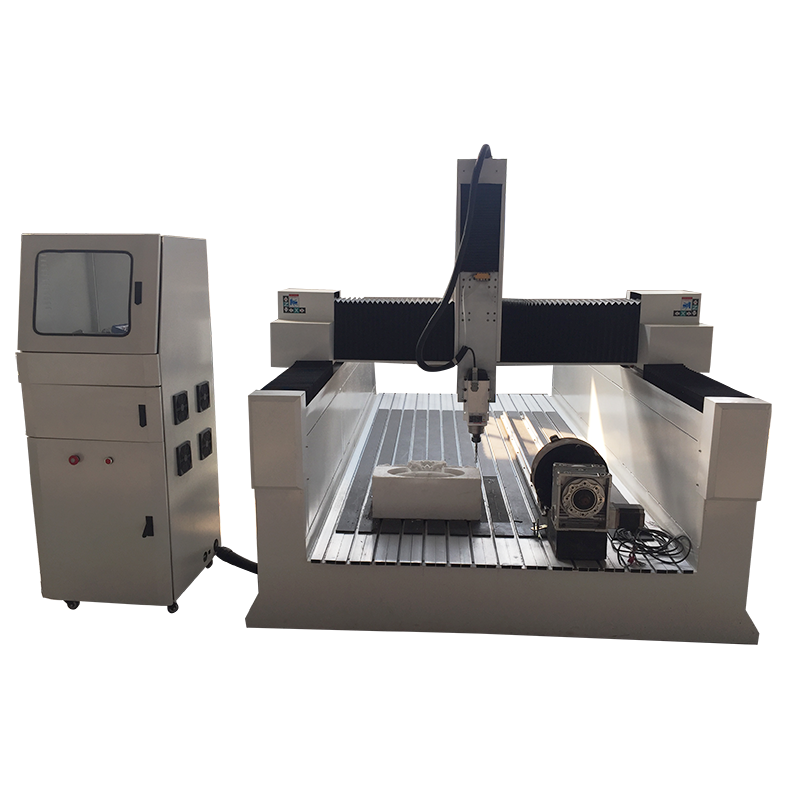

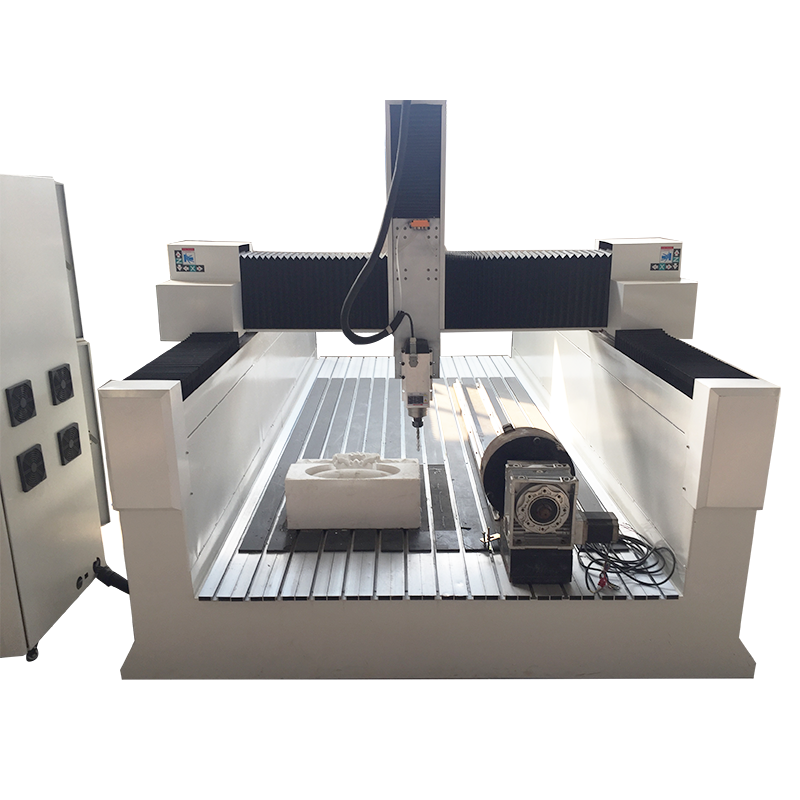

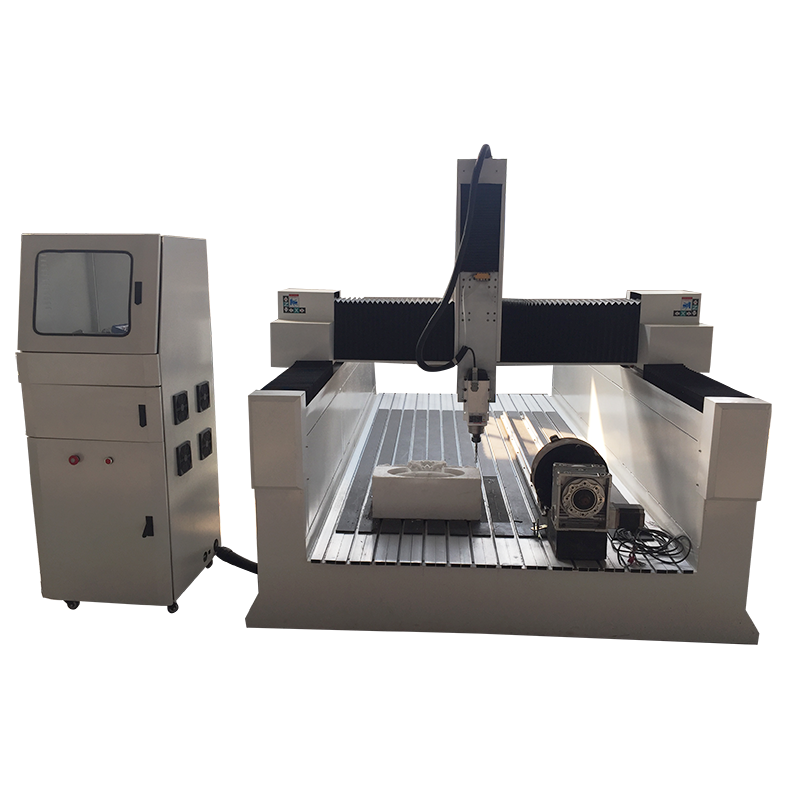

4 Axis CNC Router

SMARTECH

4 Axis CNC Router

2000*3000

220V / 380V

write

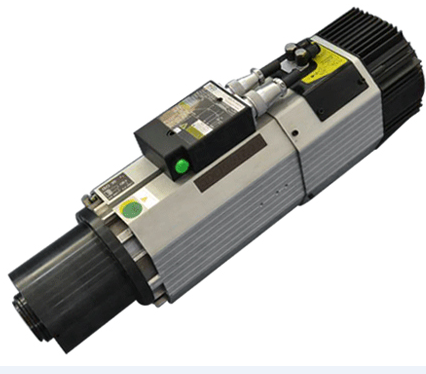

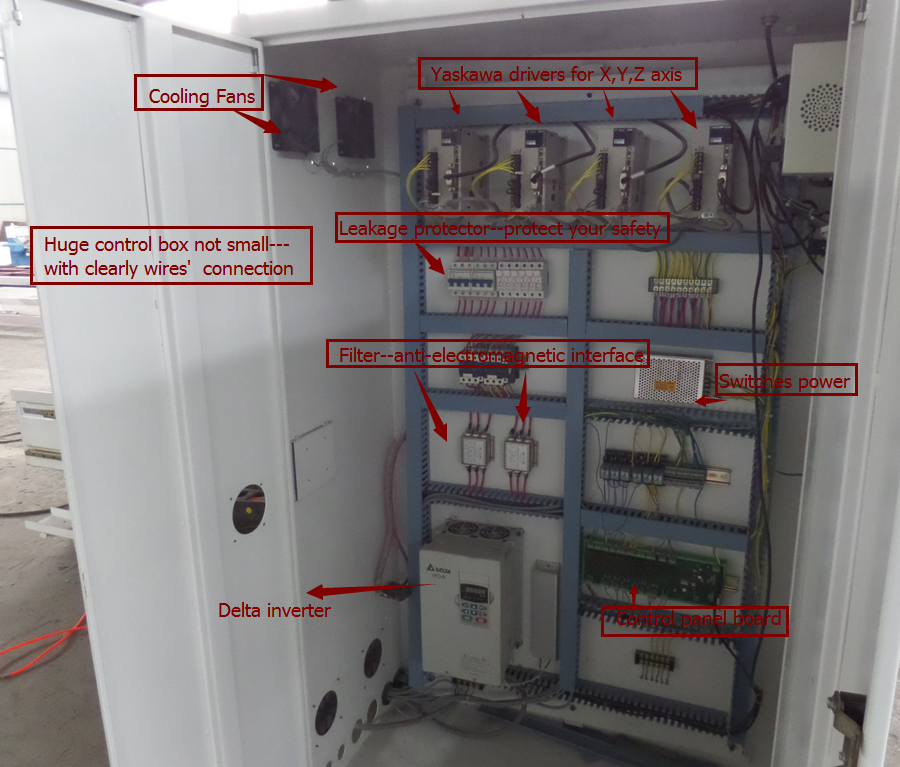

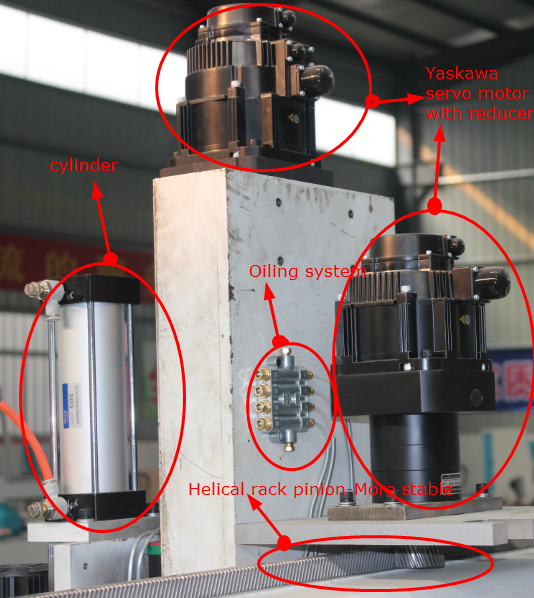

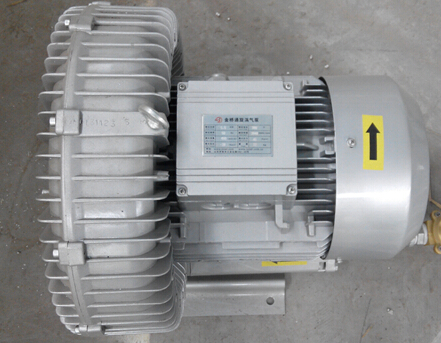

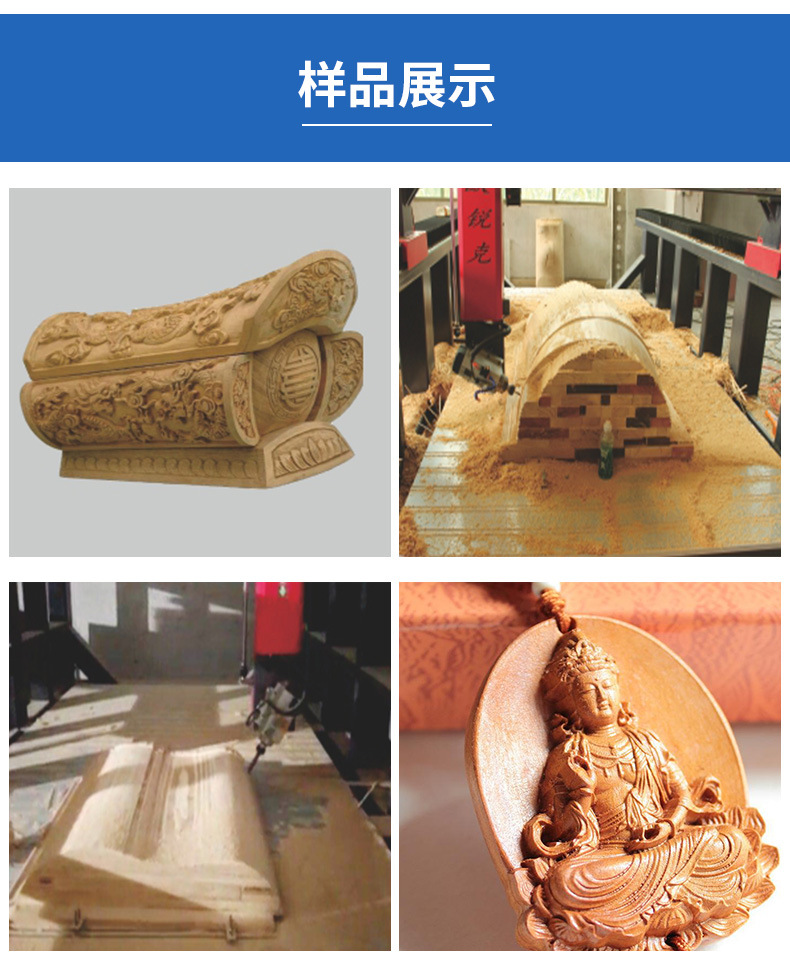

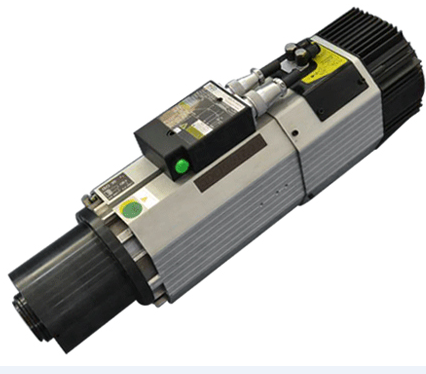

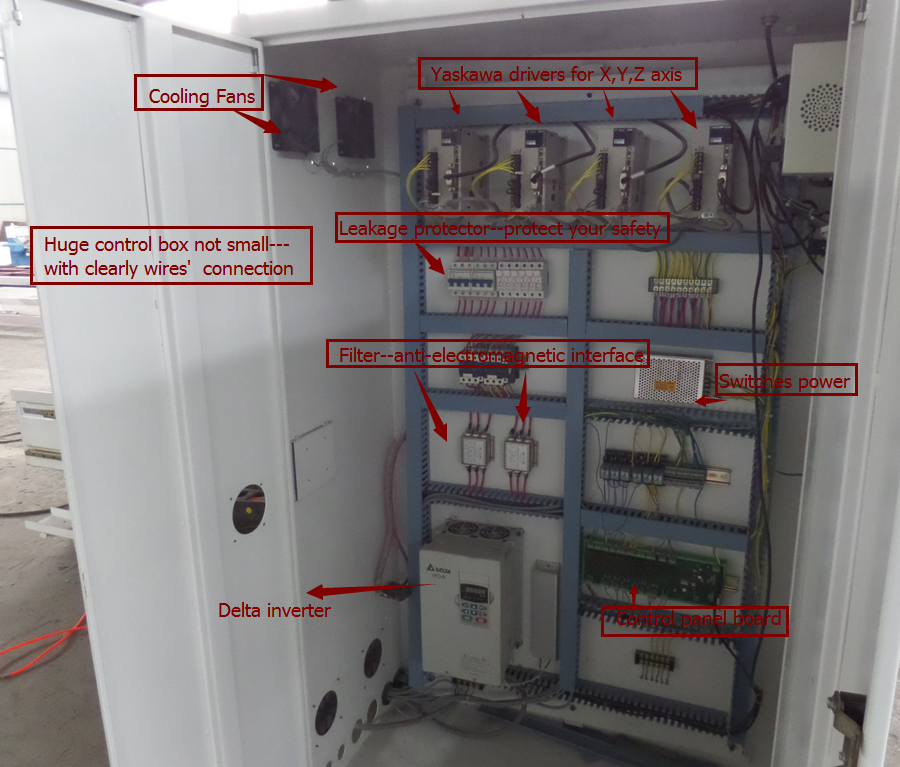

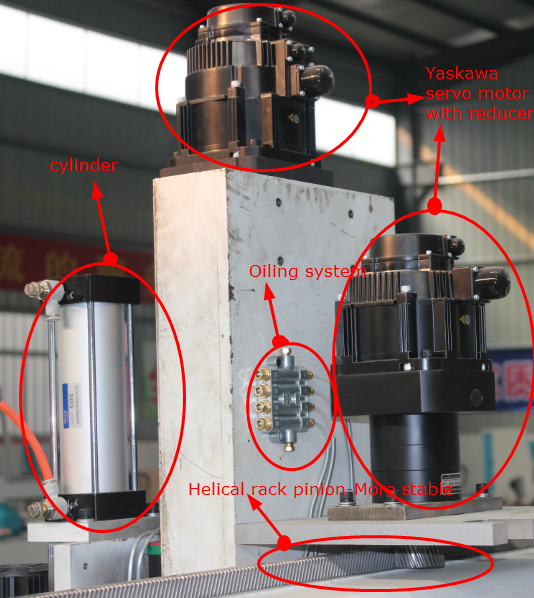

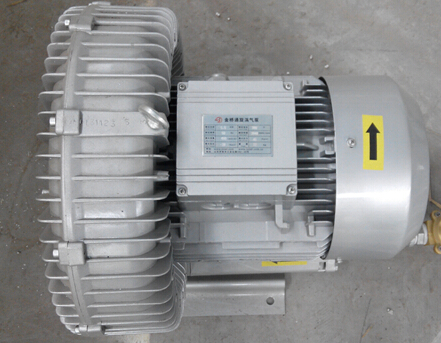

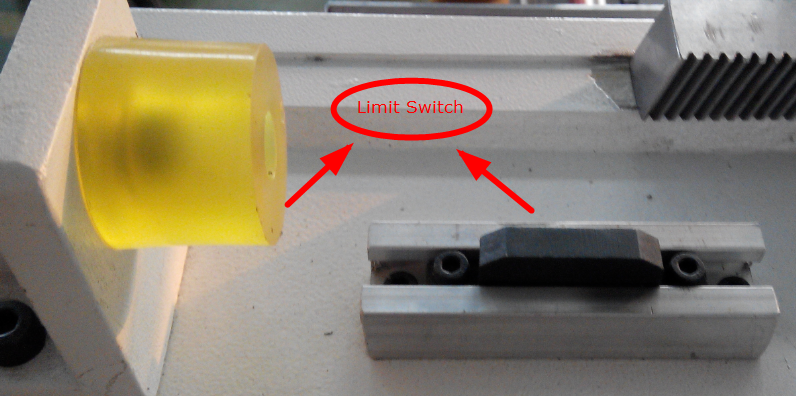

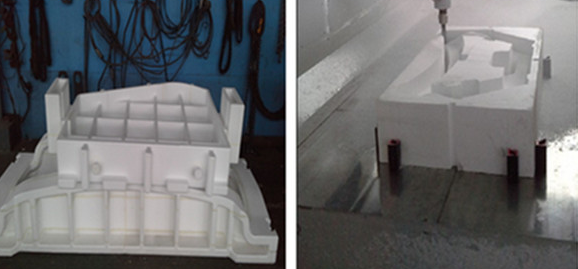

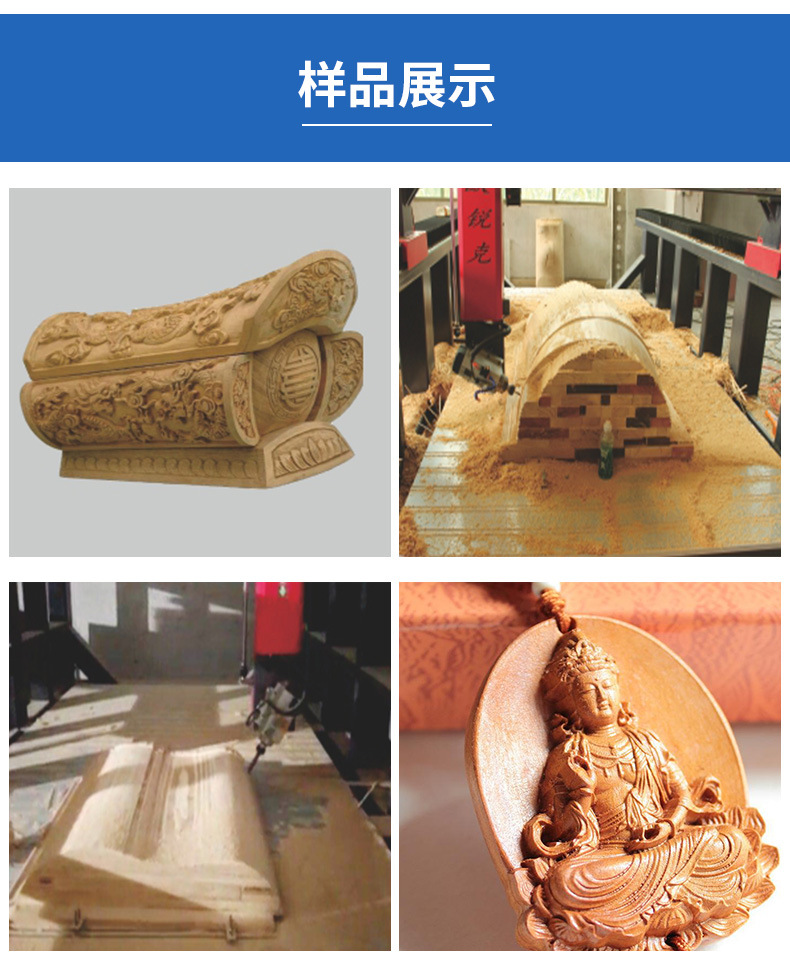

Specifications of 5 axis cnc router Machine 4 axis cnc router X,Y,Z axis working area. 2000x3000/1300*2500*800mm/1500*3000*1200mm/2000x4000x1200mm X,Y movement. Rack and pinion Z movement Ball screw transmission Guide Taiwan HIWIN/PMI 20 square rails(round rails optional) Max idling speed 40000mm/min Max engraving speed 23000mm/min Spindle power 3kw/4.5kw/6kw/7.5/9/13.5KW water cooling/air cooling (customized) Spindle speed 18000-24000rpm inverter 3.7KW/7.5KW/11kw (depend on spindle power) Drive motors Servo motors and drivers Drivers YASKAWA/Panasonic Control system Syntec control system Working voltage 220V/380V or customized Command code G code Software Powermill/solidworks/UG/Artcam,type 3,etc Collet ER 25-32 Packing dimension 3.6*2.1*1.82M(SW1530-4 Axis) Optional Spare Parts 1. Automatically tool changing --Spindle and Tool magazine 2. Real 5 axis cnc router with spindle can rotate 220 degrees.

PRODUCT CONFIGURATION

Specifications of 5 axis cnc router Machine 4 axis cnc router X,Y,Z axis working area. 2000x3000/1300*2500*800mm/1500*3000*1200mm/2000x4000x1200mm X,Y movement. Rack and pinion Z movement Ball screw transmission Guide Taiwan HIWIN/PMI 20 square rails(round rails optional) Max idling speed 40000mm/min Max engraving speed 23000mm/min Spindle power 3kw/4.5kw/6kw/7.5/9/13.5KW water cooling/air cooling (customized) Spindle speed 18000-24000rpm inverter 3.7KW/7.5KW/11kw (depend on spindle power) Drive motors Servo motors and drivers Drivers YASKAWA/Panasonic Control system Syntec control system Working voltage 220V/380V or customized Command code G code Software Powermill/solidworks/UG/Artcam,type 3,etc Collet ER 25-32 Packing dimension 3.6*2.1*1.82M(SW1530-4 Axis) Optional Spare Parts 1. Automatically tool changing --Spindle and Tool magazine 2. Real 5 axis cnc router with spindle can rotate 220 degrees.

PRODUCT CONFIGURATION