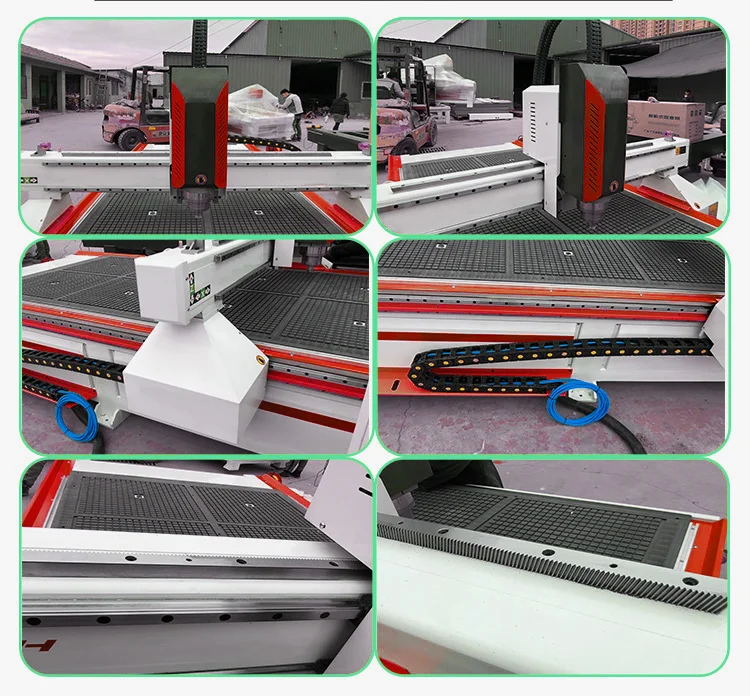

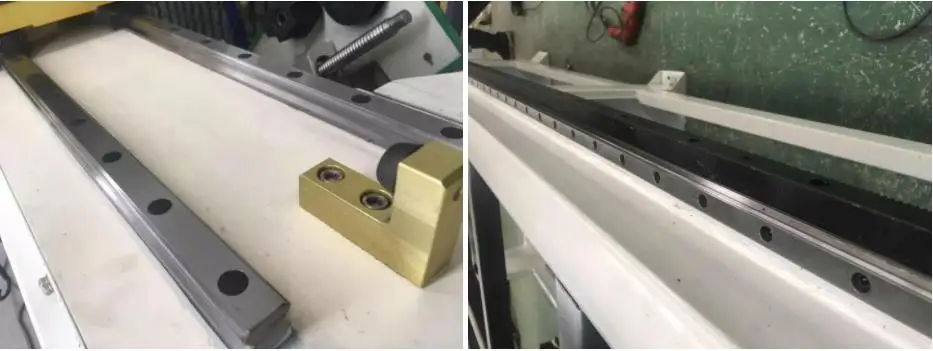

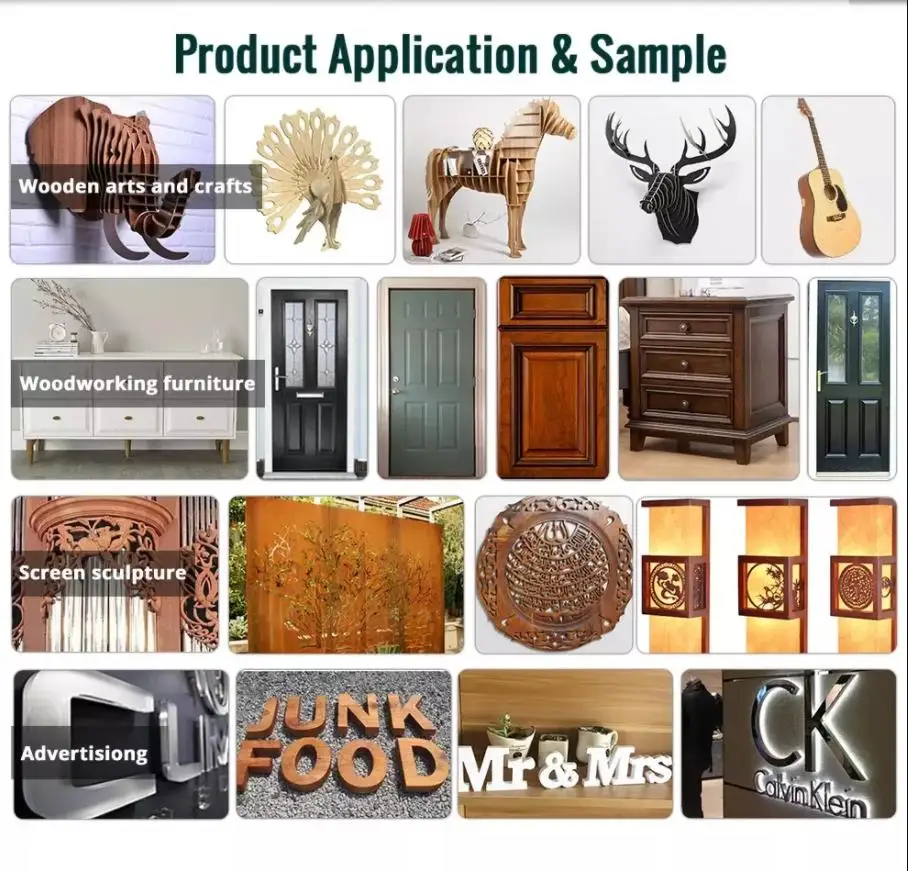

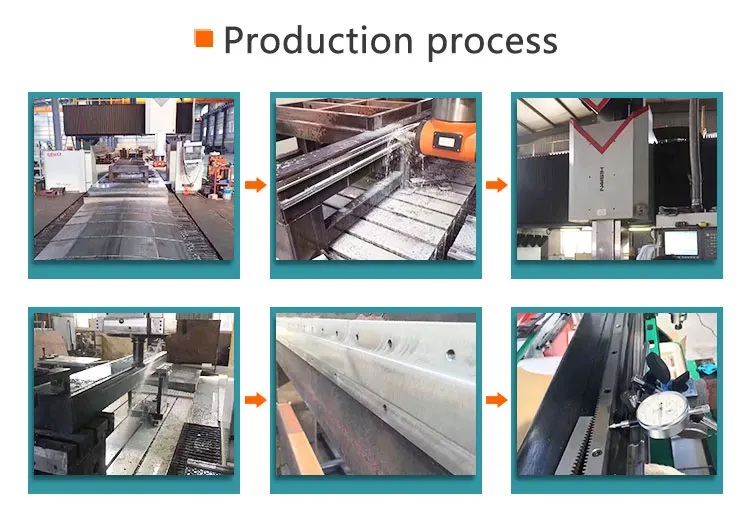

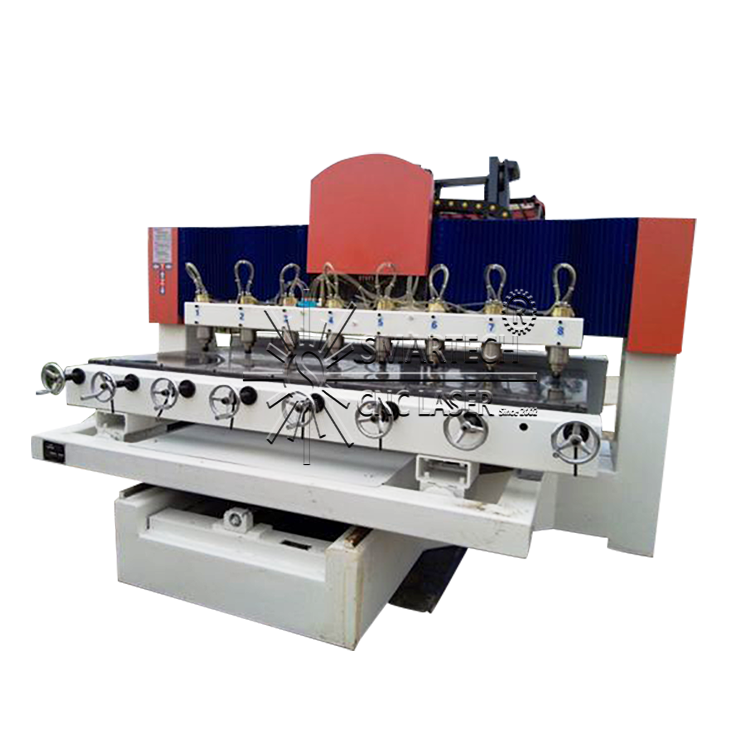

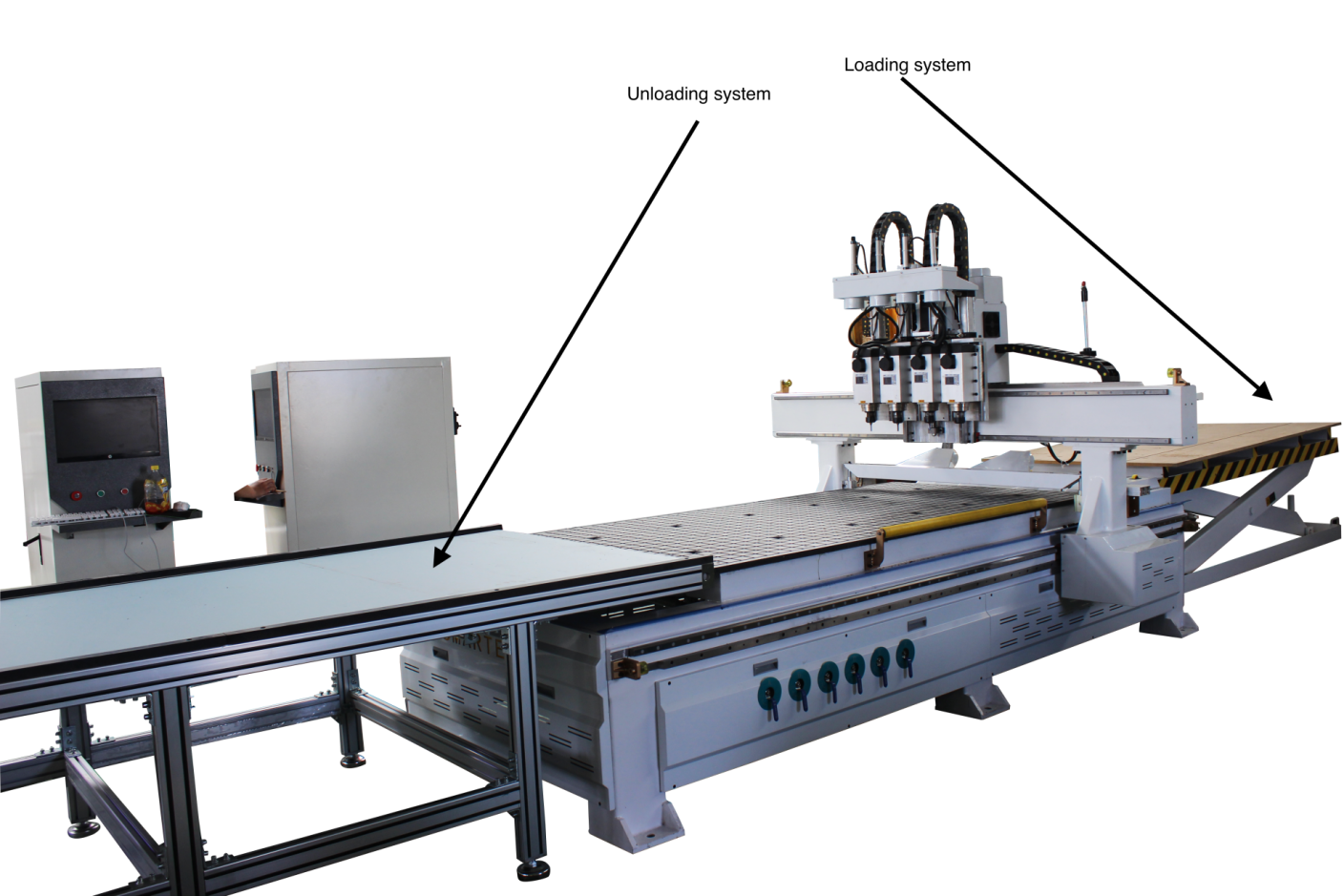

I Series Crystal Coast CNC Router Model Crystal Coast Sider Rotary Working area X-axis travel 1300mm Y-axis travel 2500mm Z-axis travel 200mm Transmission device X-axis transmission mode precision helical tooth gear transmission Y-axis transmission mode precision helical tooth gear transmission Z-axis transmission mode precision TBI ball screw Travel speed 0-25000mm/min Working speed 0-18000mm/min Table structure T-slot table/vacuum table Driving mode patent stepper reducer structure Spindle power 3.7KW Water-cooled spindle motor Spindle speed 0-24000rpm Diameter of cutter φ3.175-φ12.7mm Command code HPGL G-code Working voltage aC220V/Hz Device interface standard PCI/USB interface Optional Control system NC-studio controller/DSP controller/Mach3 controller Resolution 0.01mm Machine size 3380*2120*1750mm Machine weight 1500kg Rotary 80-300mm Diameter, 2000mm length. Optional parts servo drive system, vacuum device, vacuum adsorption device, replace high-power spindle motor drive The scope of application advertising, furniture, sheet metal processing, handicrafts, decoration, and other industries Performance characteristics high strength, easy storage, high speed, complete circuit accessories, automatic knife tool, and so on