| Availability: | |

|---|---|

SFM30 (MOPA LASER MARKER)

SMARTECH

10W/20W/30W/50W/60W/100W

-High Frequency Line Processing

-especially for deep engraving works and high work requirements

SF series pulsed fiber lasers make use of master oscillator power amplifier (MOPA) configuration, and show excellent laser performance as well as high level of temporal pulse shaping controll ability. Compared with Q-switching technology, SF series fiber laser is more flexible, supporting wider range of frequency adjustment and higher precise control. As compared to JPT M series fiber laser, the MOPA configuration adopts the pulse compensation, which enables minimum pulses deformation, hence makes the peak power of the fiber laser higher.

Mopa Fiber Laser Marking Machine power source

Advantages of MOPA laser

1.For short pulses and lower pulse energy, the material is e.g. heated less and the area of the heat affected zone is reduced. This results in more advantages and possibilities for laser marking metals and plastics:

2.Less burning/melting in the edge area of metal engravings

3.Less heat development during annealing markings on metal, which leads to a better corrosion behavior

4.Controlled melting of plastics

5.Less foaming with plastics

6.More homogeneous and sometimes higher-contrast markings on some plastics

7.The advantages of the conventional fiber laser sources remain unchanged:

8.maintenance-free

9.long service life

10.air-cooled

11.economic purchase price

12.High output power, high optical quality and compact size

13.Cleaner mark edges and faster marking speeds

14.Reliability and a lower cost of ownership

15.Plus, you’ll get the very best in efficiency. Fiber lasers are up to ten times more efficient than traditional YAG laser systems, and they use little to no energy in standby mode.

Mopa Fiber Laser Marking Machine working samples:

Colorful Laser Marking

What materials could be colourful mark-able? They are stainless steel, titanium, chrome plate and transition metals. The specific material grades and surface finishes can have an impact on the marking process as can the thickness of the material.

Brushed surfaces are more difficult to mark with a consistent colour mark due to the magnitude of the roughness in terms of peak to trough being significantly larger than the depth of oxides being generated. In these cases the grain of the material can still be seen in the mark. Polished surfaces have been found to be far more consistent in terms of colour. In this case the grain of the mark is more aligned with the marking direction.Smartech Mopa laser marking machine is especially for the colorful marking and deep thickness marking demands.

Mopa laser marking machine technicial data:

NO | Model | SF10W/20W/30W /50W |

1 | Laser Type | Mopa |

2 | Working area | 110*110mm (160X160 For option,price is the same) |

3 | Laser Wavelength | 1064nm |

4 | Repetition Precision | ±0.001 |

5 | Marking mode | static |

6 | Lifting height | 500mm |

7 | Laser / PC Connectivity | USB connection |

8 | Response time | 0.05ms |

9 | Frequency of pulse | 20-100KHz |

10 | Scanning Speed: | 0-8000mm/s |

11 | Marking speed | ≤7000mm/s |

12 | Spot diameter | ≤40 micron (F-theta 160) |

13 | Marking lines | 1-10 lines(in the marking area) |

14 | Energy per pulse (PRR = 20 kHz) | 0.95 mJ |

15 | Laser switching ON/off time | 180 μsec |

16 | Marking content | Text,pattern,date,bar code,etc |

17 | Operation system | Microsoft Windows XP or Windows 2000 |

18 | Control software | EZCAD control software |

19 | Graphic format supported | bmp, jpg, gif, tga, png,tif,ai,dxf,dst,plt,etc. |

20 | Machine power | ≤0.5KW |

21 | Operation temperature | 5℃-40℃ |

22 | Package size/ Net weight/Gross weight | 760×680×770mm/65KG/100kg |

23 | Relative moisture | ≤ 90%,no fog |

24 | Supply Voltage | 220V/50Hz/10A or customized |

FAQ

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A:Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping

ways? A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China, about 2hours train from Beijing and Shanghai. -Q Can I arrange sample for cutting test? A:Yes, always welcome.

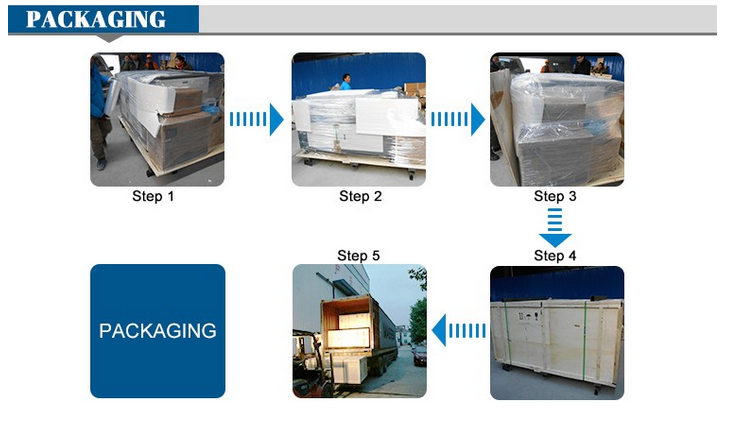

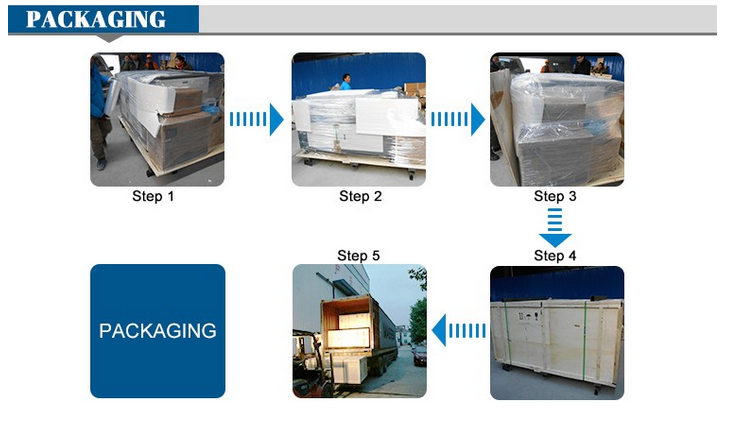

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95%

customers can learn by themselves.

-High Frequency Line Processing

-especially for deep engraving works and high work requirements

SF series pulsed fiber lasers make use of master oscillator power amplifier (MOPA) configuration, and show excellent laser performance as well as high level of temporal pulse shaping controll ability. Compared with Q-switching technology, SF series fiber laser is more flexible, supporting wider range of frequency adjustment and higher precise control. As compared to JPT M series fiber laser, the MOPA configuration adopts the pulse compensation, which enables minimum pulses deformation, hence makes the peak power of the fiber laser higher.

Mopa Fiber Laser Marking Machine power source

Advantages of MOPA laser

1.For short pulses and lower pulse energy, the material is e.g. heated less and the area of the heat affected zone is reduced. This results in more advantages and possibilities for laser marking metals and plastics:

2.Less burning/melting in the edge area of metal engravings

3.Less heat development during annealing markings on metal, which leads to a better corrosion behavior

4.Controlled melting of plastics

5.Less foaming with plastics

6.More homogeneous and sometimes higher-contrast markings on some plastics

7.The advantages of the conventional fiber laser sources remain unchanged:

8.maintenance-free

9.long service life

10.air-cooled

11.economic purchase price

12.High output power, high optical quality and compact size

13.Cleaner mark edges and faster marking speeds

14.Reliability and a lower cost of ownership

15.Plus, you’ll get the very best in efficiency. Fiber lasers are up to ten times more efficient than traditional YAG laser systems, and they use little to no energy in standby mode.

Mopa Fiber Laser Marking Machine working samples:

Colorful Laser Marking

What materials could be colourful mark-able? They are stainless steel, titanium, chrome plate and transition metals. The specific material grades and surface finishes can have an impact on the marking process as can the thickness of the material.

Brushed surfaces are more difficult to mark with a consistent colour mark due to the magnitude of the roughness in terms of peak to trough being significantly larger than the depth of oxides being generated. In these cases the grain of the material can still be seen in the mark. Polished surfaces have been found to be far more consistent in terms of colour. In this case the grain of the mark is more aligned with the marking direction.Smartech Mopa laser marking machine is especially for the colorful marking and deep thickness marking demands.

Mopa laser marking machine technicial data:

NO | Model | SF10W/20W/30W /50W |

1 | Laser Type | Mopa |

2 | Working area | 110*110mm (160X160 For option,price is the same) |

3 | Laser Wavelength | 1064nm |

4 | Repetition Precision | ±0.001 |

5 | Marking mode | static |

6 | Lifting height | 500mm |

7 | Laser / PC Connectivity | USB connection |

8 | Response time | 0.05ms |

9 | Frequency of pulse | 20-100KHz |

10 | Scanning Speed: | 0-8000mm/s |

11 | Marking speed | ≤7000mm/s |

12 | Spot diameter | ≤40 micron (F-theta 160) |

13 | Marking lines | 1-10 lines(in the marking area) |

14 | Energy per pulse (PRR = 20 kHz) | 0.95 mJ |

15 | Laser switching ON/off time | 180 μsec |

16 | Marking content | Text,pattern,date,bar code,etc |

17 | Operation system | Microsoft Windows XP or Windows 2000 |

18 | Control software | EZCAD control software |

19 | Graphic format supported | bmp, jpg, gif, tga, png,tif,ai,dxf,dst,plt,etc. |

20 | Machine power | ≤0.5KW |

21 | Operation temperature | 5℃-40℃ |

22 | Package size/ Net weight/Gross weight | 760×680×770mm/65KG/100kg |

23 | Relative moisture | ≤ 90%,no fog |

24 | Supply Voltage | 220V/50Hz/10A or customized |

FAQ

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A:Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping

ways? A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China, about 2hours train from Beijing and Shanghai. -Q Can I arrange sample for cutting test? A:Yes, always welcome.

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95%

customers can learn by themselves.