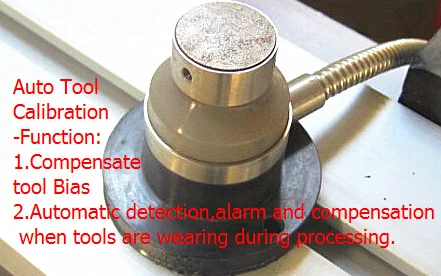

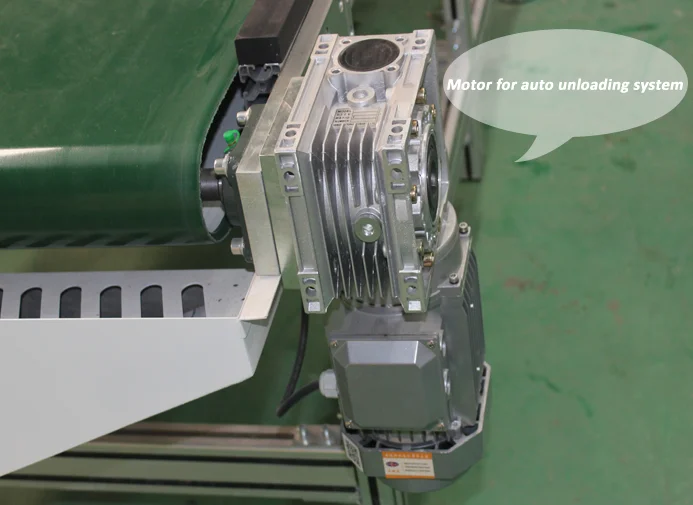

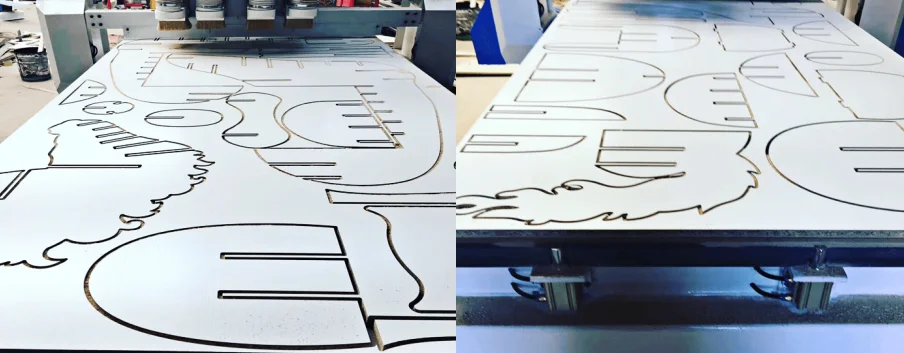

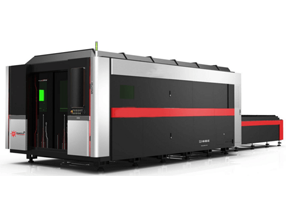

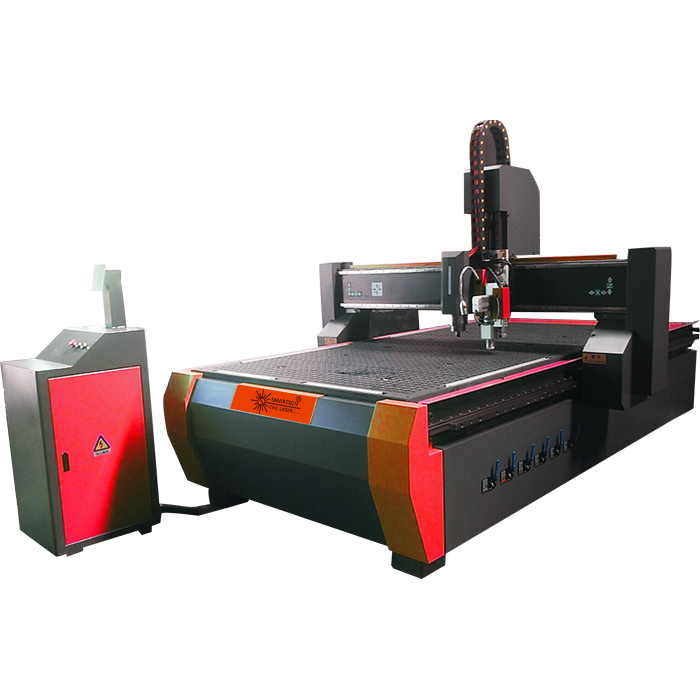

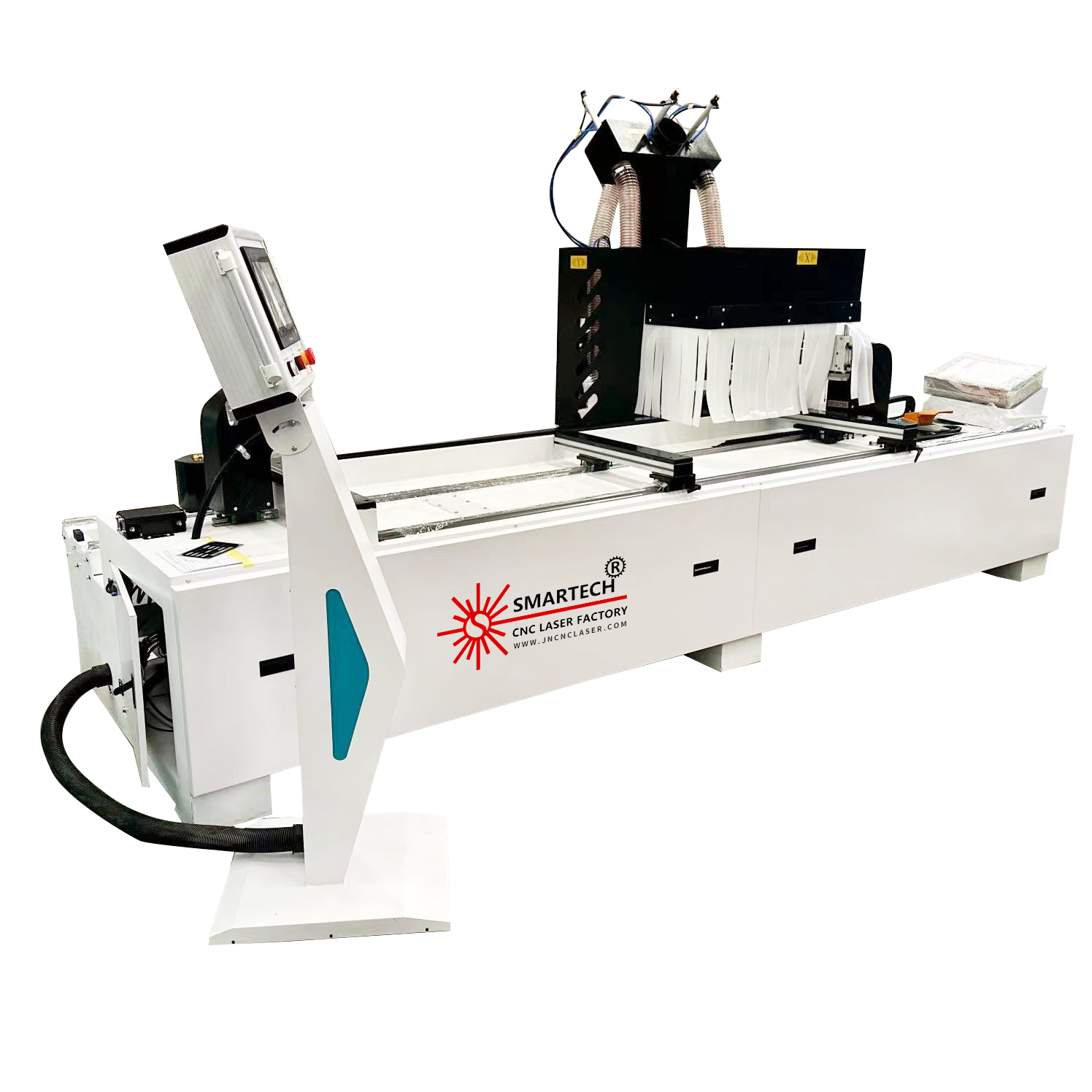

#Yaskawa servo motor driver FOR X Y Z AXIS. #Vacuum pump 7.5KW*2 pieces #Delta inverter #Automatic tool sensor #Aluminium table combines with vacuum table. #8 magazine tools holder #Dust collector with dust hood, pipeline switch #Syntec control system #Strong Seamless Steel frame #3 Years’ warranty,Lifetime after sale service #On-site technicians are available. #Origin point for table protection. #Safety sensor for option(protect human safety)