COMMODITY&DESCRIPTION

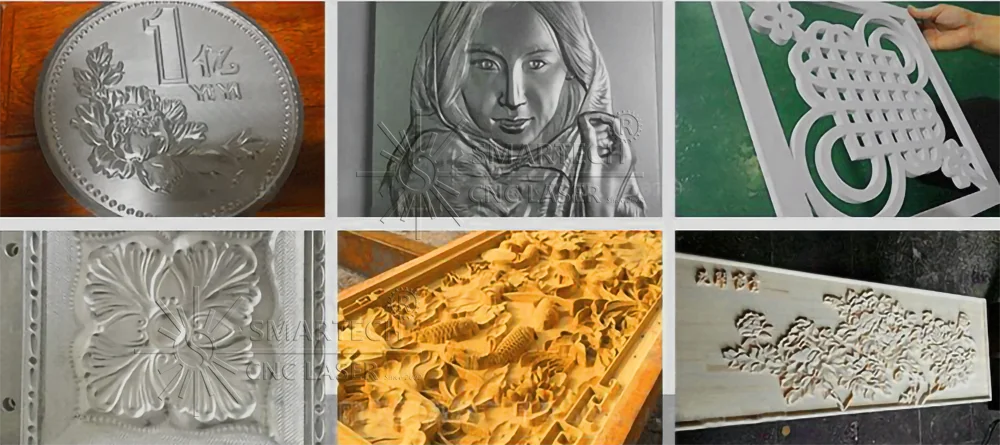

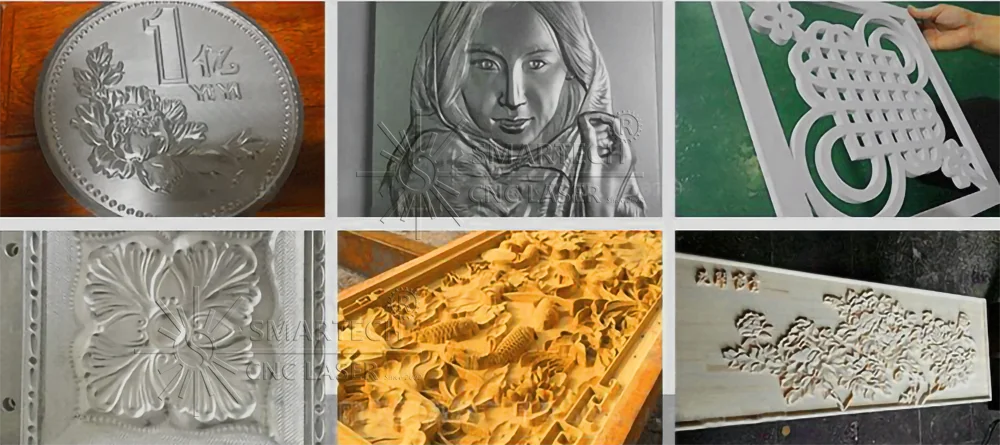

SWS Series 2040 CNC Router(CE standard) Working area: 2000x4000mm Original HIWIN Rails imported from Taiwan. Helical rack pinion gear transmission(more stable) T-slot table water tank (Stainless steel type, not iron.) Auto Tool sensor NC Studio controller Best inverter (best in China) Original Lead Shine Stepper motor and drivers 860 3.7 KW Water-cooling especial spindle for hard materials Water pump for spindle cooling Artcam /JD paint Software Limit switches for all x,y,z axis 3 pieces cooling sprayers Whole set tools #Used for Aluminium,granite,marble,glass,wood etc 3 Years warranty(we would send new parts for free for any damages during warranty)