| Availability: | |

|---|---|

Main features of cnc moulding machine:

SMARTECH

Main features of cnc moulding machine:

1700 * 1800 * 1850mm

220/50HZ AC 380V

write

Product Overview

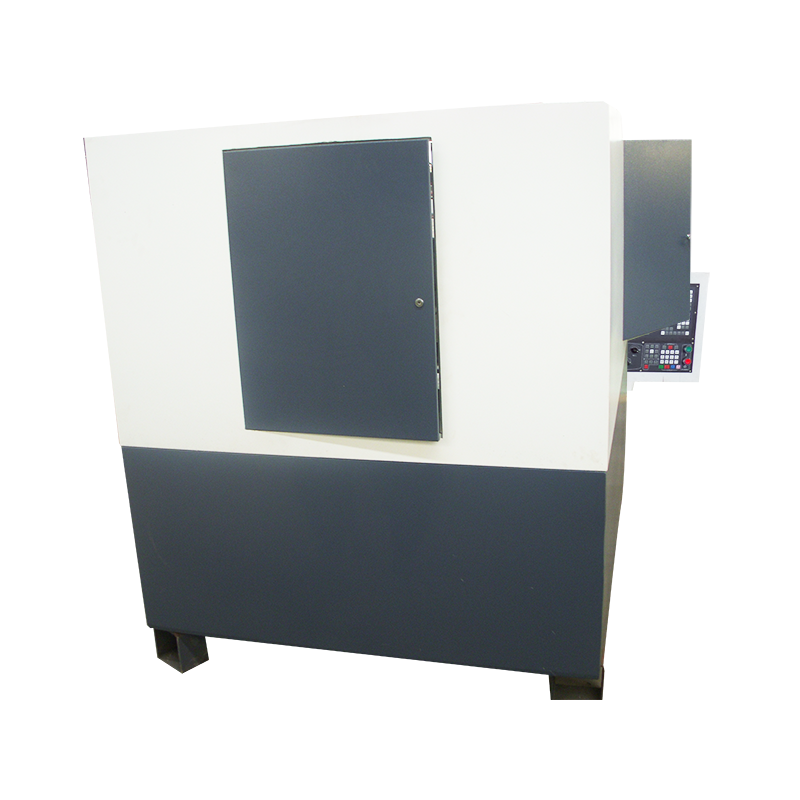

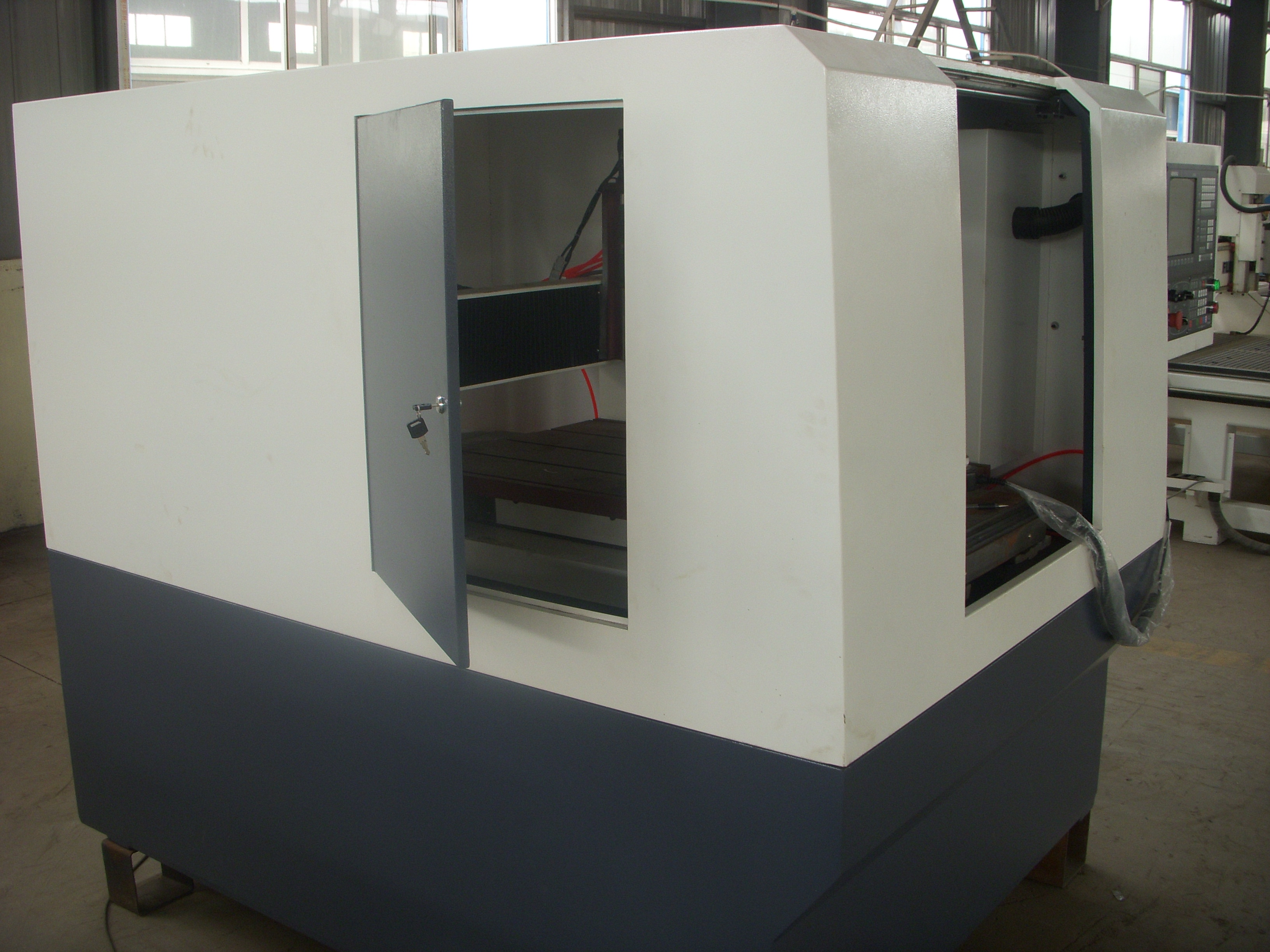

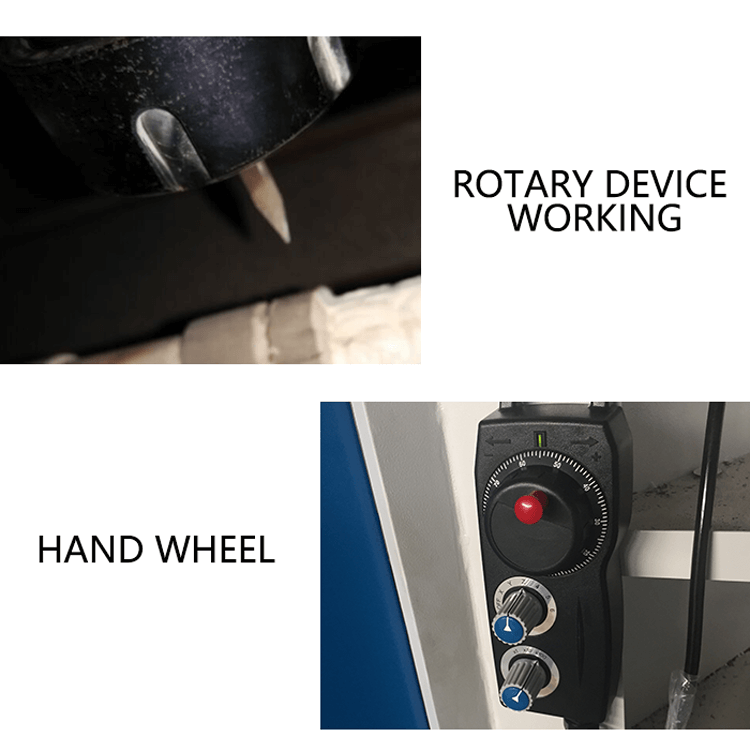

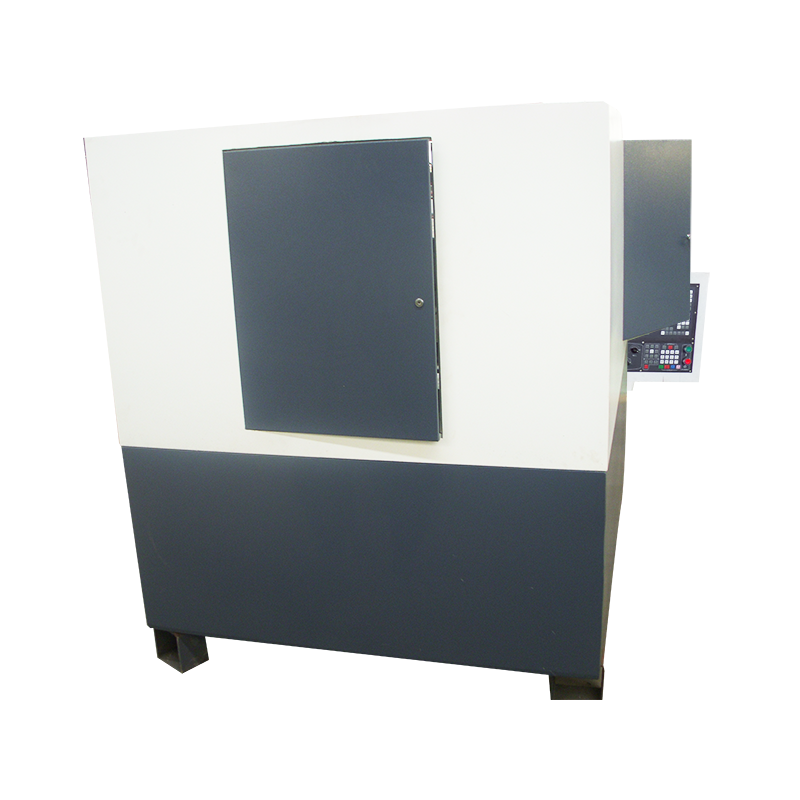

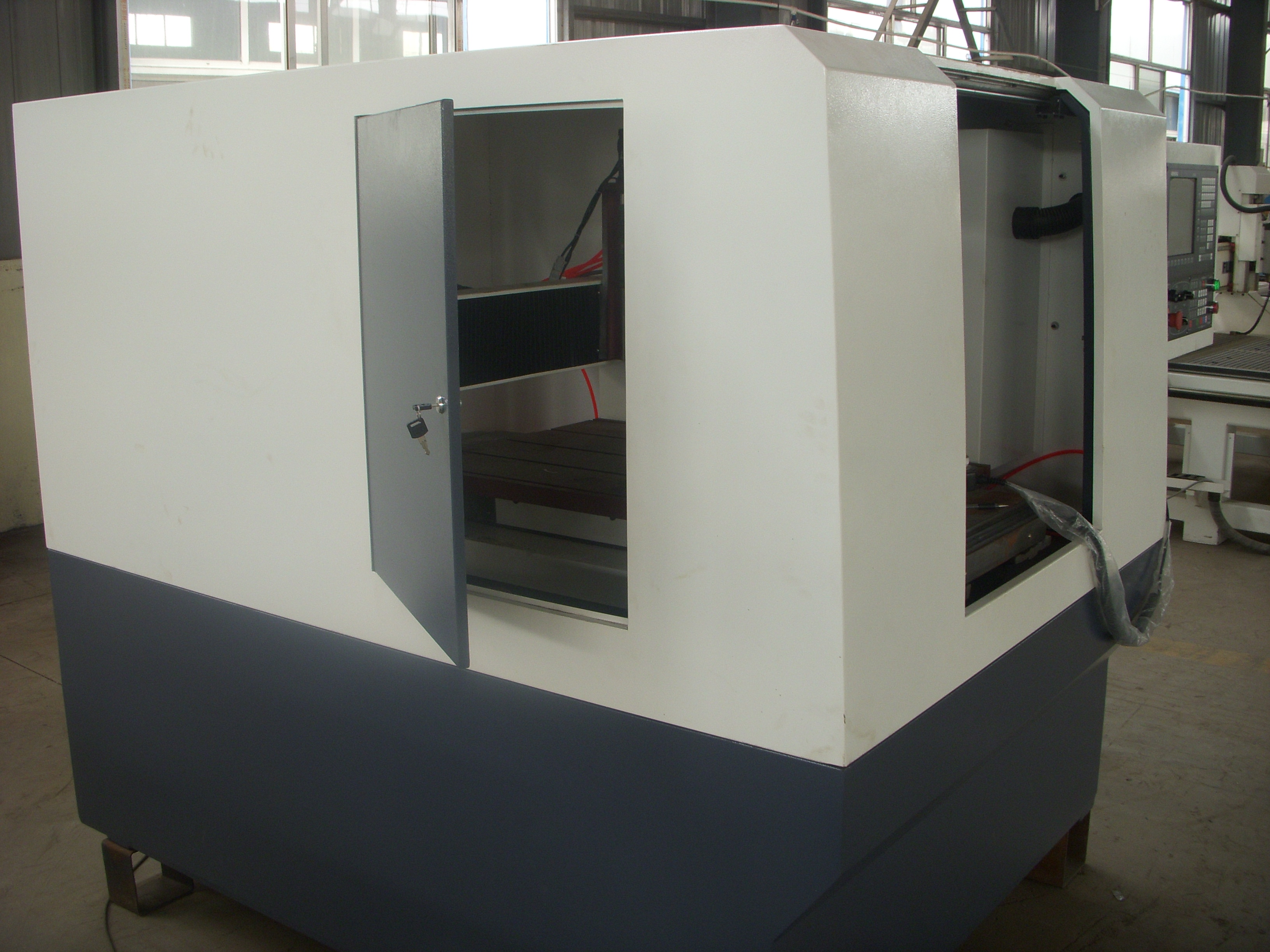

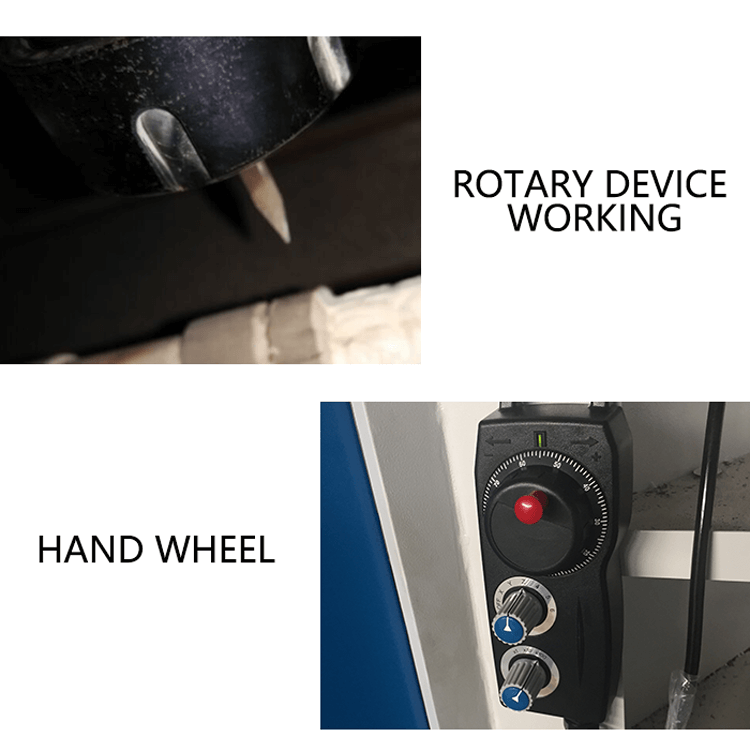

1.Main features of cnc moulding machine:

1). Whole machine cast by iron, very strong, table moving, high precision.

2). Imported Hiwin/PMI/TRV square rails and TBI ball screw for 3 axis.

3). Working area 600*600*200mm, Z axis zone can according your need make it.

4). Japan Yaskawa servo motor and drivers,leadshine hybrid servo motor for option.

5). TK100 controller, DSP control system, Syntec,NC Studio and Mach3 for option.

6). Machine with lubrication system, spindle cover, Japan OMRON limit switch and Schneider electrical components

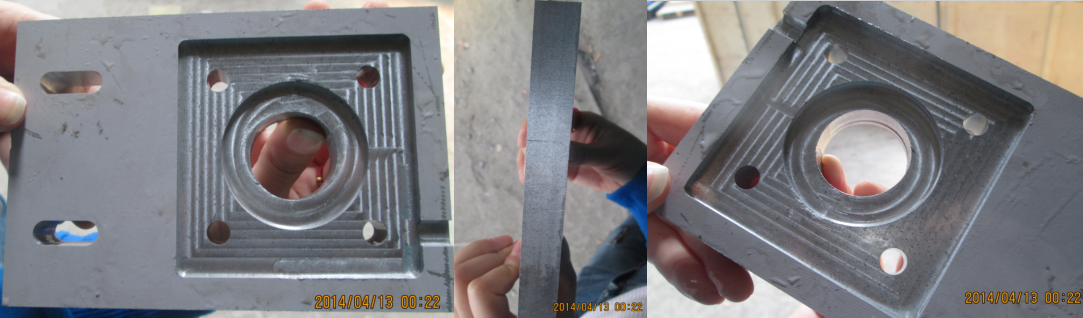

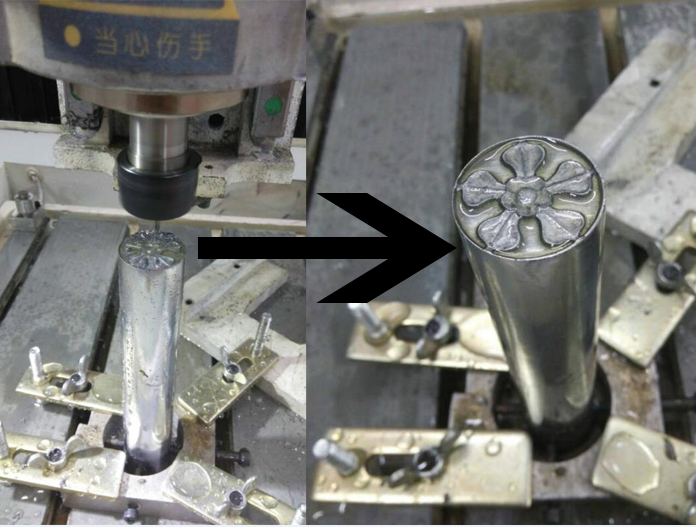

Application of cnc moulding machine:

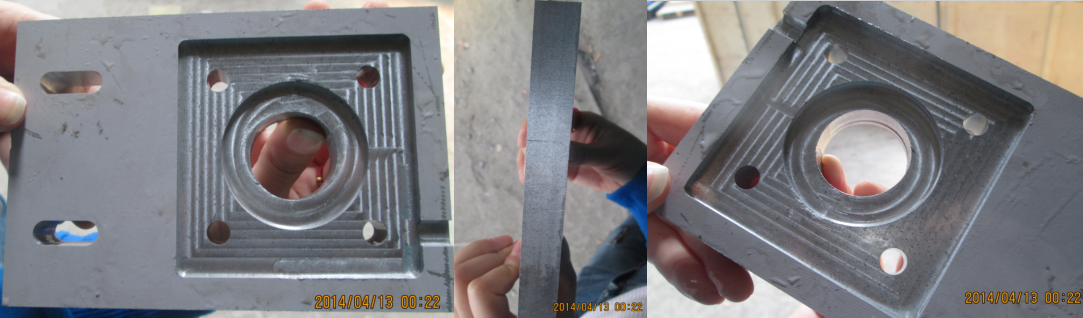

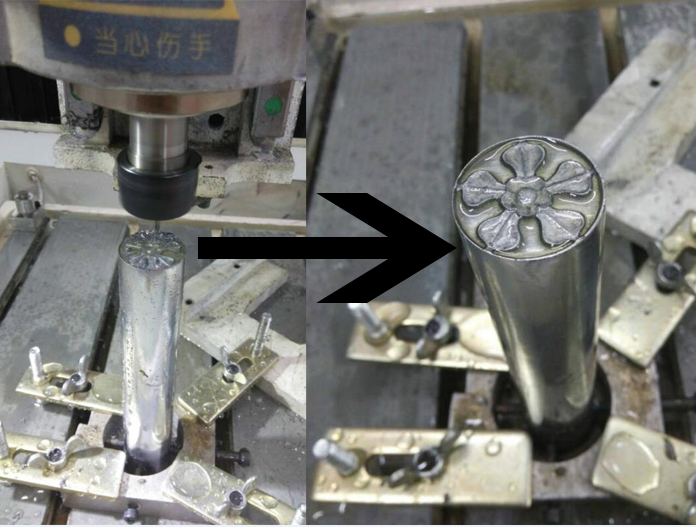

1).It is suitable for engraving,milling and drilling compactly all sorts of materials such as steel,copper,aluminum and plastics.

2).Widely apply to automotive,injection mould,ironware mould and engrave mould industries.

3).Especially designed for engraving and milling molds,eyeglasses, watch,panel,badge,brand, graphics and words of three-dimensional and outside surface's sleeking of large size

Model

SM0404 SM0606

Travelling size

X working area 400mm / 600mm

Y working area 400mm / 600mm

Z working area 200mm

Accuracy

Working Accuracy ±0.01mm

Repositioning Resolution ±0.01 mm

Table

Surface

stainless steel T-slot table

Guide rail

Taiwan HIWIN square guide rail 25 PMI/TRV

Transmission

X/Y/Z Axis Taiwan TBI ball screw

Structure

Lathe Structure

Integral cast iron

Speed

Rapid Travel Rate 15000mm/min

Working Speed 10000mm/min

Spindle

Spindle Power 2.2KW /3KW

Spindle Speed 0-24000rpm

Inverter Fuling inverter DELTA

Working Drive motor

Stepper motor /JAPAN YASKAWA Servo motor

Command Language G code(optional:HPGL)

Others

Working Voltage AC220/50HZ AC 380V

Operating System Original NC studio SYNTEC

Compatible Software

Artcam Type3

Weight

Gross weight 1800kg 1900KG

Net weight 1500kg 1600KG

Package

1. Protective film package and fumigation-free plywood case.

2. OEM and package can according to customer requirements.

FAQ

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A:Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways?

A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your workshop after machine arrival.

-Q Where is your factory located? How can I visit there? A:Jinan City, Shandong Province, China,

about 2hours train from Beijing and Shanghai.

-Q Can I arrange sample for cutting test?

A:Yes, always welcome.

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality

control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95%

customers can learn by themselves.

Product Overview

1.Main features of cnc moulding machine:

1). Whole machine cast by iron, very strong, table moving, high precision.

2). Imported Hiwin/PMI/TRV square rails and TBI ball screw for 3 axis.

3). Working area 600*600*200mm, Z axis zone can according your need make it.

4). Japan Yaskawa servo motor and drivers,leadshine hybrid servo motor for option.

5). TK100 controller, DSP control system, Syntec,NC Studio and Mach3 for option.

6). Machine with lubrication system, spindle cover, Japan OMRON limit switch and Schneider electrical components

Application of cnc moulding machine:

1).It is suitable for engraving,milling and drilling compactly all sorts of materials such as steel,copper,aluminum and plastics.

2).Widely apply to automotive,injection mould,ironware mould and engrave mould industries.

3).Especially designed for engraving and milling molds,eyeglasses, watch,panel,badge,brand, graphics and words of three-dimensional and outside surface's sleeking of large size

Model

SM0404 SM0606

Travelling size

X working area 400mm / 600mm

Y working area 400mm / 600mm

Z working area 200mm

Accuracy

Working Accuracy ±0.01mm

Repositioning Resolution ±0.01 mm

Table

Surface

stainless steel T-slot table

Guide rail

Taiwan HIWIN square guide rail 25 PMI/TRV

Transmission

X/Y/Z Axis Taiwan TBI ball screw

Structure

Lathe Structure

Integral cast iron

Speed

Rapid Travel Rate 15000mm/min

Working Speed 10000mm/min

Spindle

Spindle Power 2.2KW /3KW

Spindle Speed 0-24000rpm

Inverter Fuling inverter DELTA

Working Drive motor

Stepper motor /JAPAN YASKAWA Servo motor

Command Language G code(optional:HPGL)

Others

Working Voltage AC220/50HZ AC 380V

Operating System Original NC studio SYNTEC

Compatible Software

Artcam Type3

Weight

Gross weight 1800kg 1900KG

Net weight 1500kg 1600KG

Package

1. Protective film package and fumigation-free plywood case.

2. OEM and package can according to customer requirements.

FAQ

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A:Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways?

A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your workshop after machine arrival.

-Q Where is your factory located? How can I visit there? A:Jinan City, Shandong Province, China,

about 2hours train from Beijing and Shanghai.

-Q Can I arrange sample for cutting test?

A:Yes, always welcome.

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality

control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95%

customers can learn by themselves.