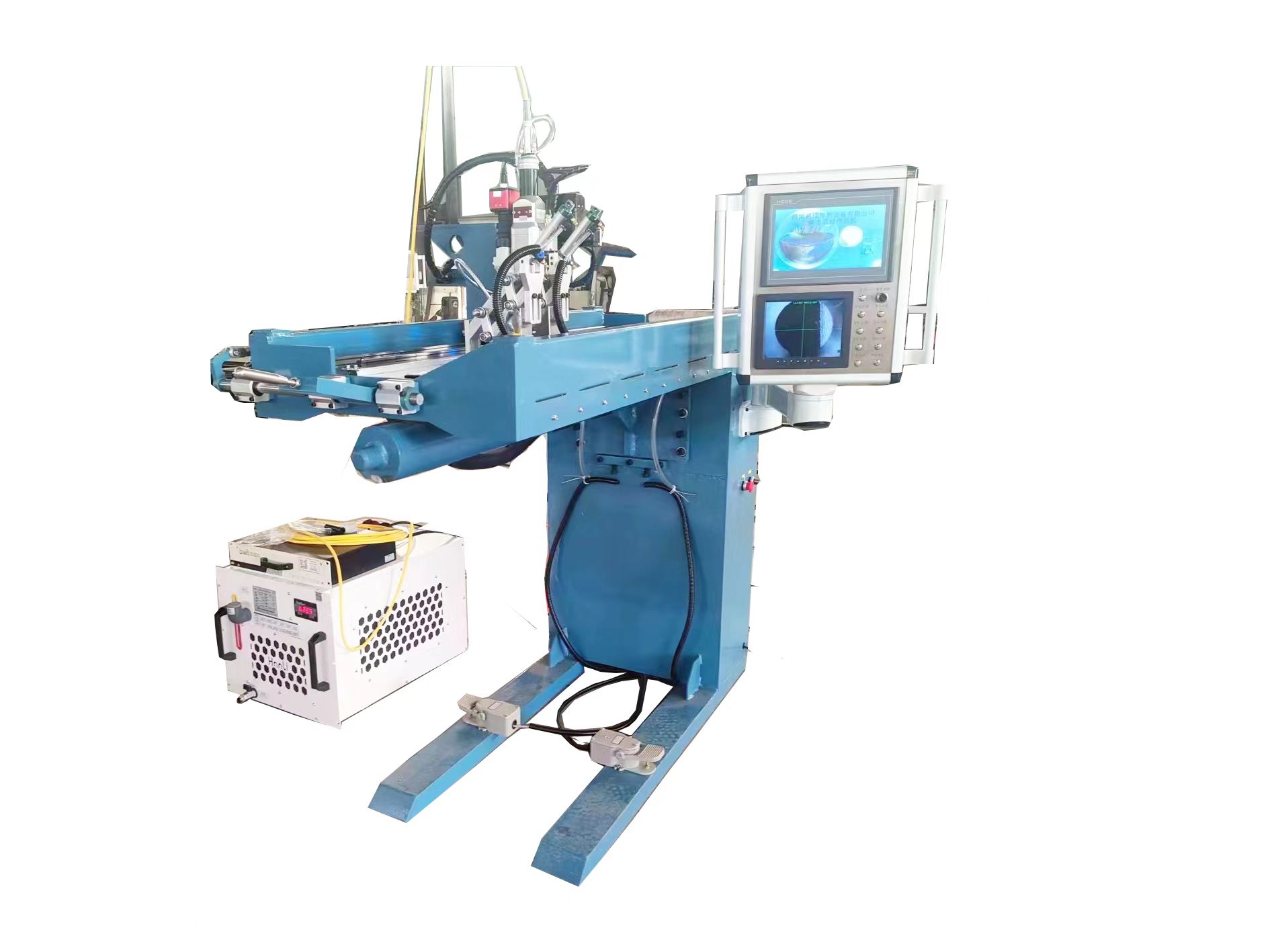

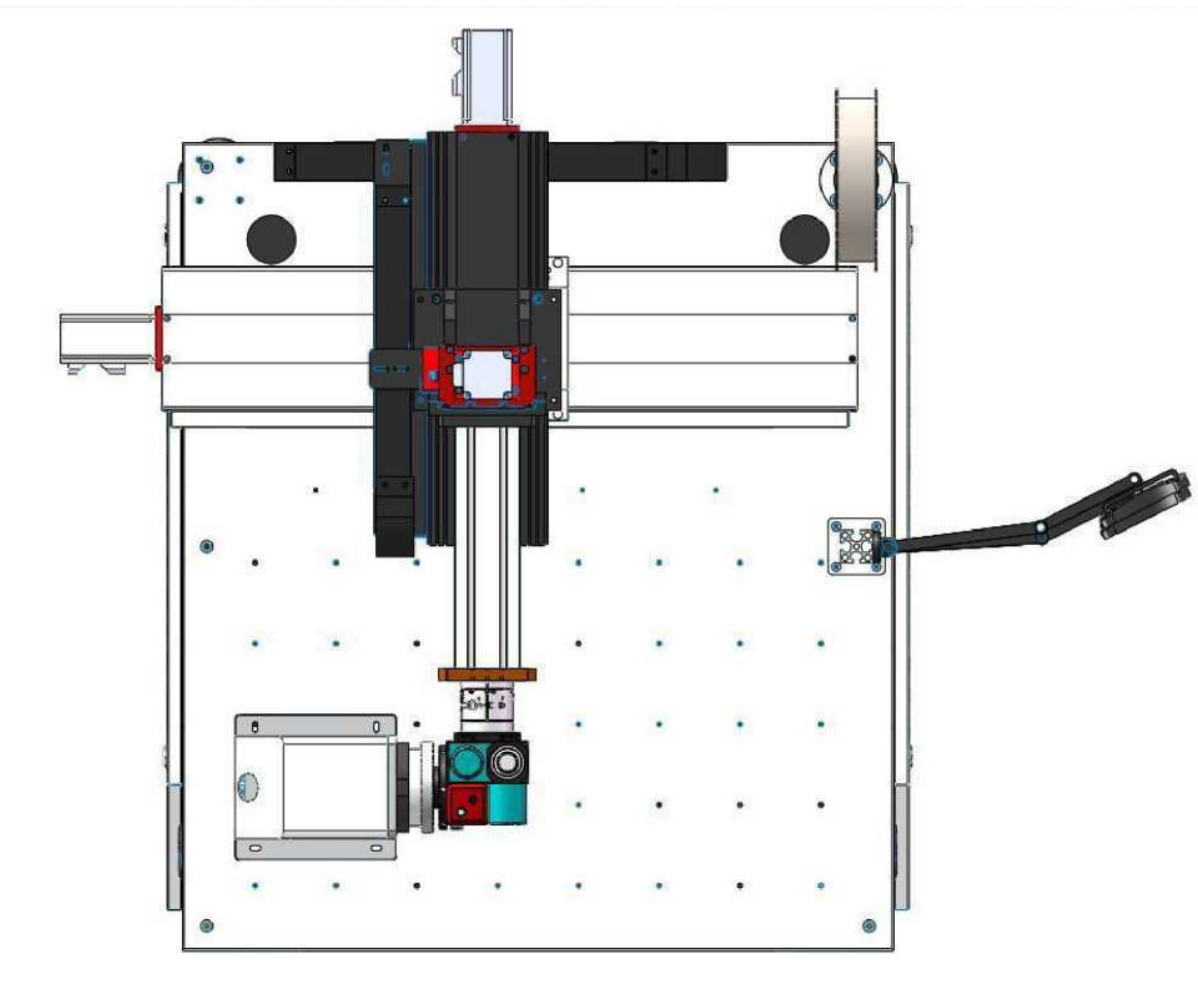

#PC for portable type/computer for table type. HP/lenovo/dell brand Memory=4GB....one set

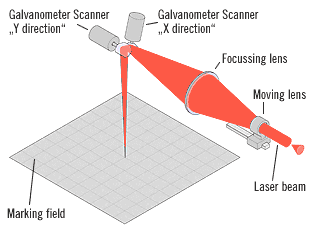

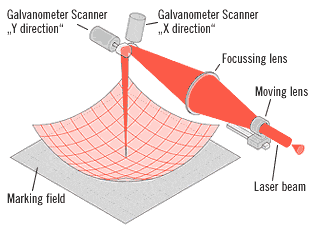

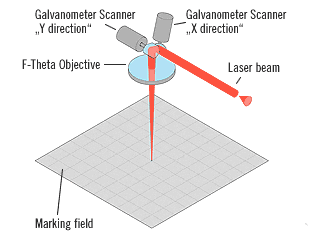

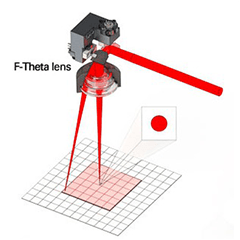

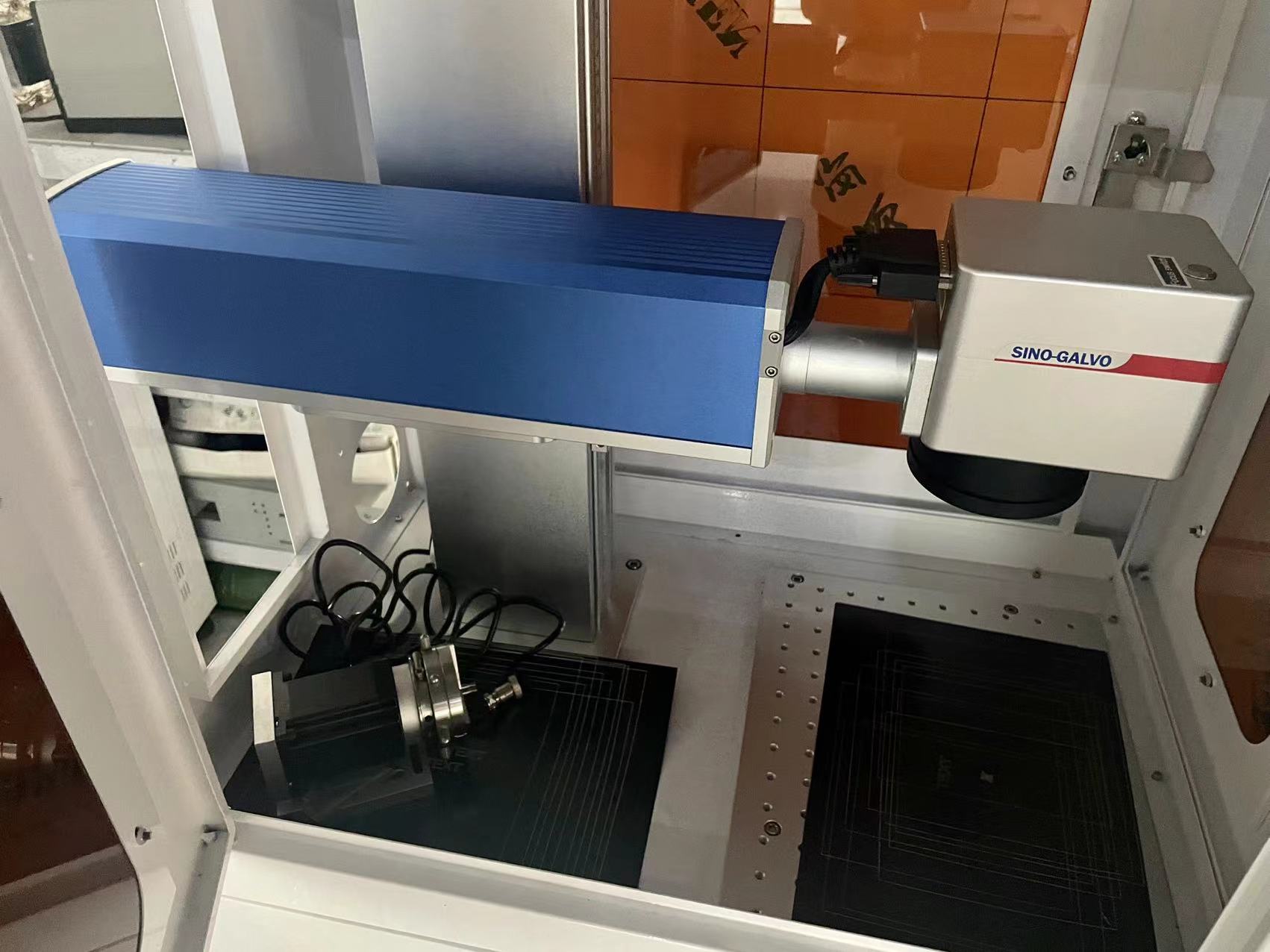

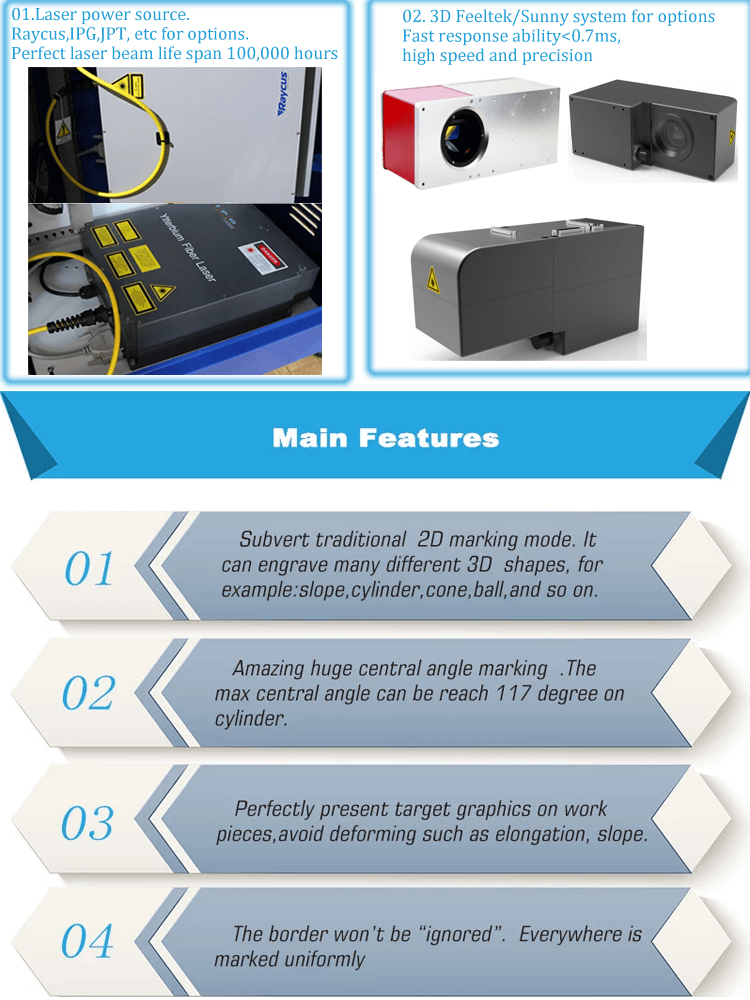

#Digital scanning head&Original Singapore imported high transmissivity......one set

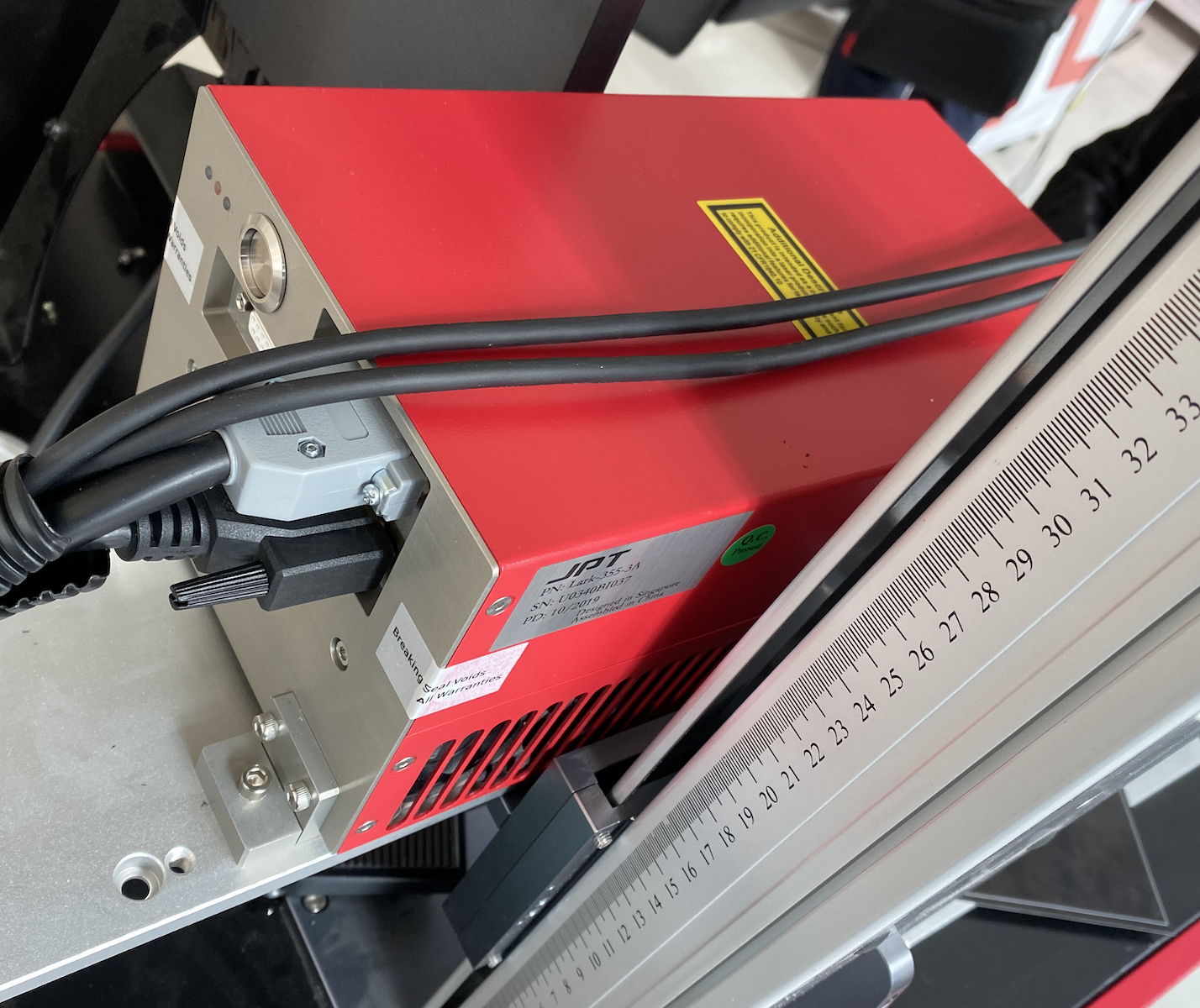

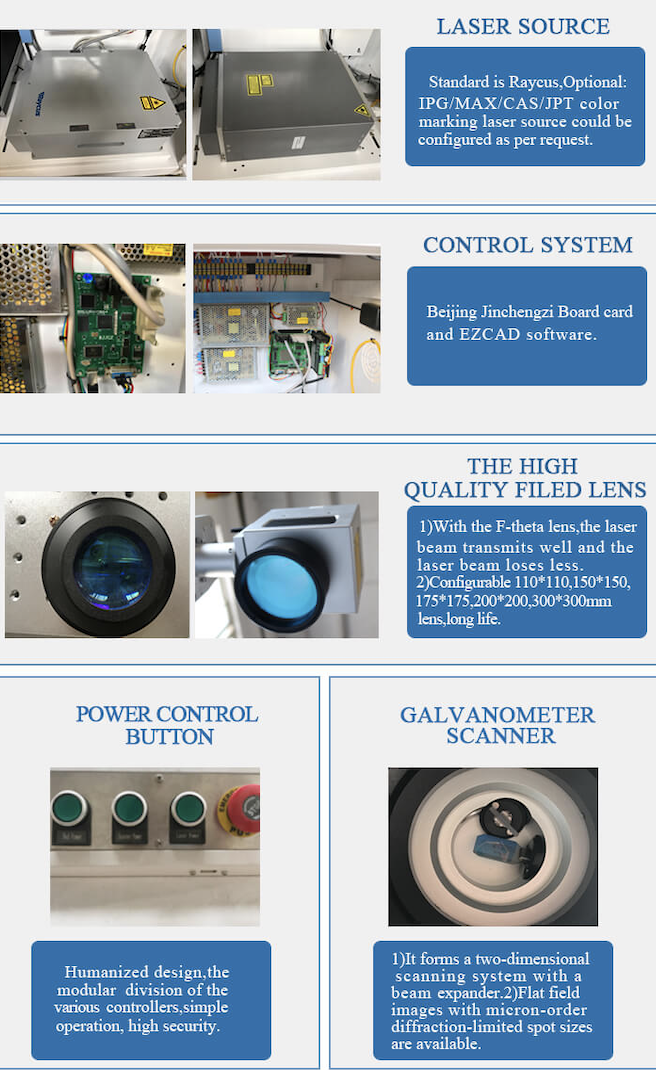

#Original JPTM7 MOPA device,IF copy double refund(not JPTM1)............one set

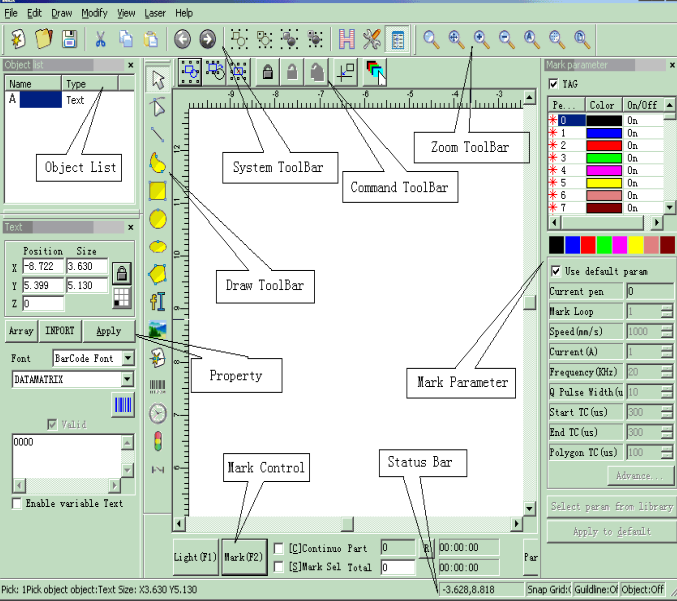

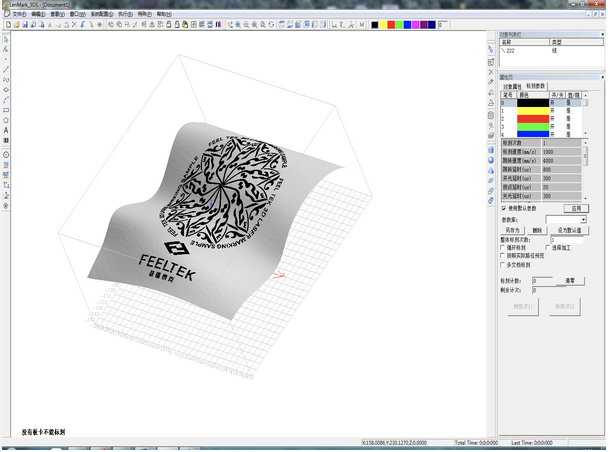

#Latest original EZCAD /Lenmark software…….................................one set

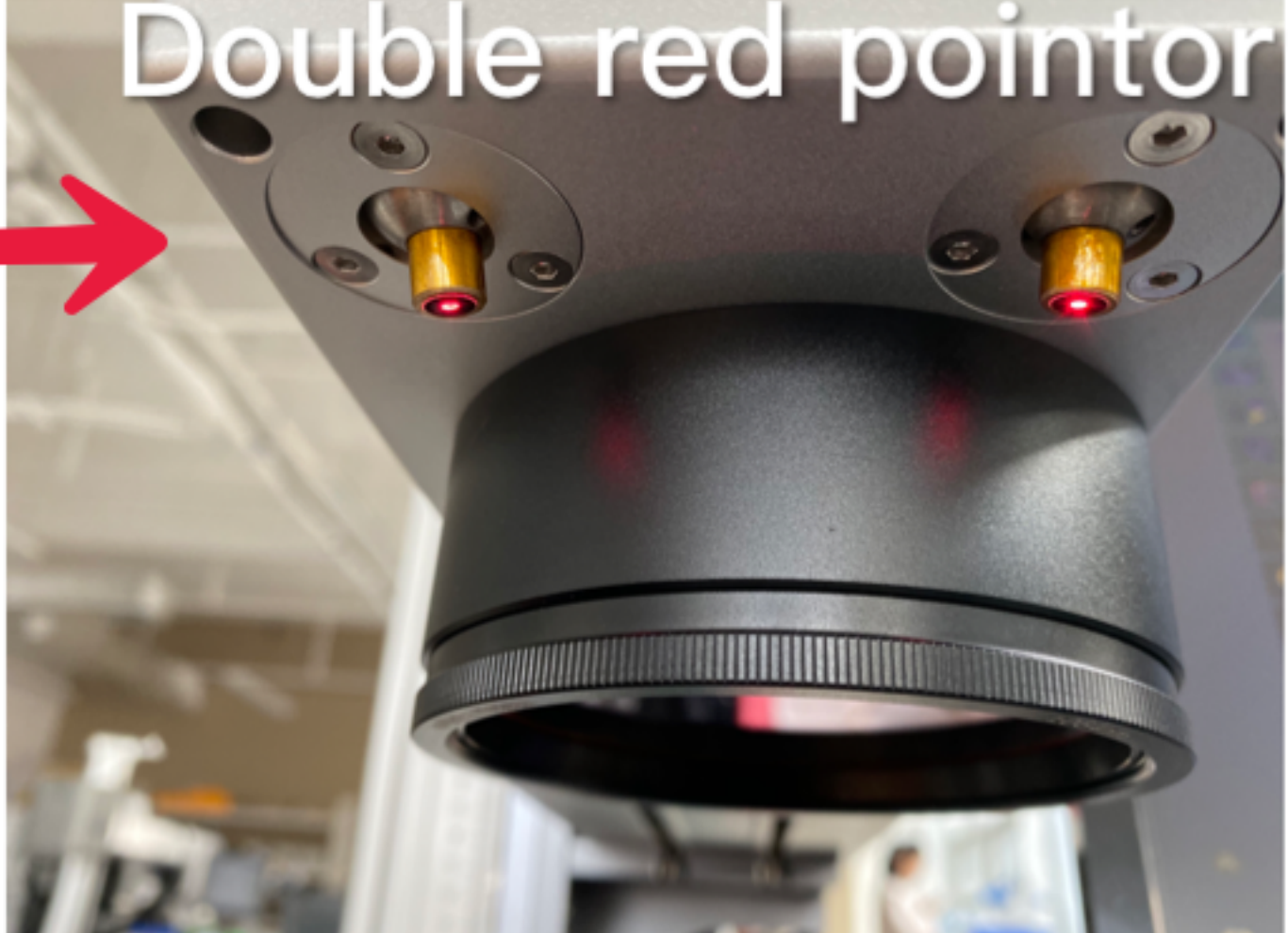

#Double red pointer for focusing ,not single ......................................................one set

#Up down table & controlling cabinet easy to carry...........................................…one set

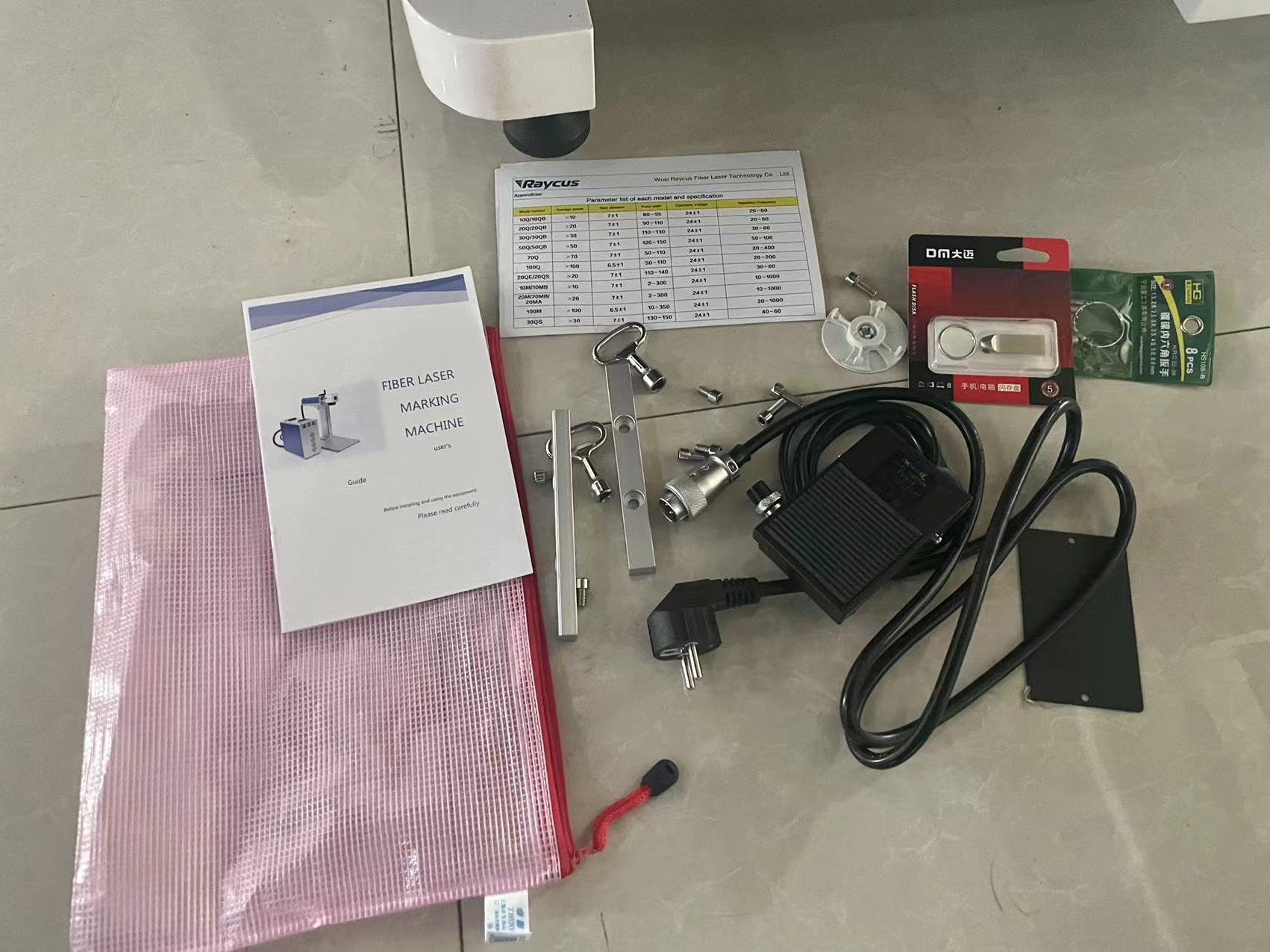

#Tools and tool box comes with machine.........................................one set

#Protective glasses for free.................................................one set

#Light for night works(comes with portable model)............................................one set

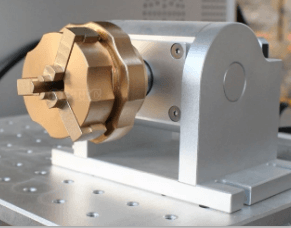

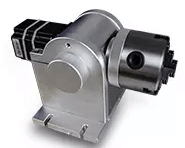

#Galvo galvanometer.....................one set

#Data connection.......................…one set

#Foot pedal.................................. .one set

Famous brands electrical parts

Include each necessary part,you could use directly after received machine.