| Availability: | |

|---|---|

smartech

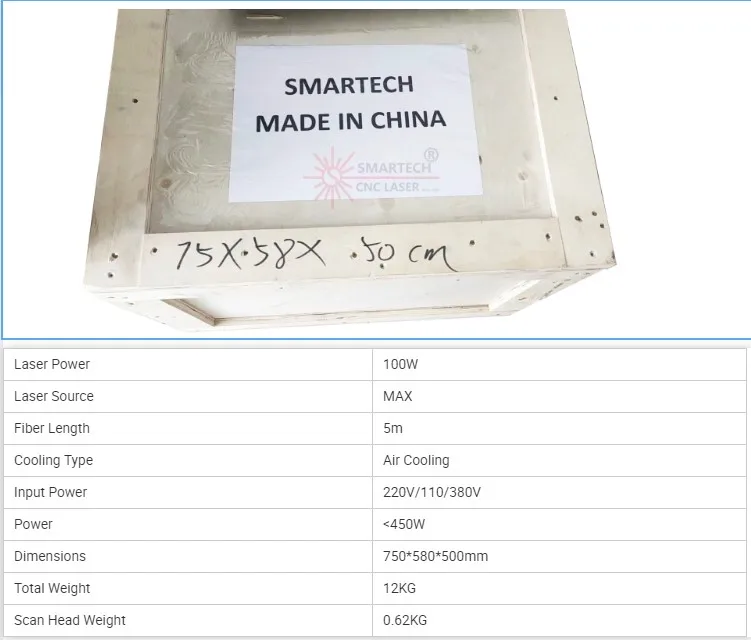

750*580*500mm

220V/110/380V

Scope of application of industril laser cleaning device

Small area or local cleaning applications, paint removal, red rust removal, black rust removal, oil removal; stainless steel and aluminum alloy

and other alloys before and after welding; removal of copper oxide, zirconia, etc., metal surface wool and surface wiredrawing.

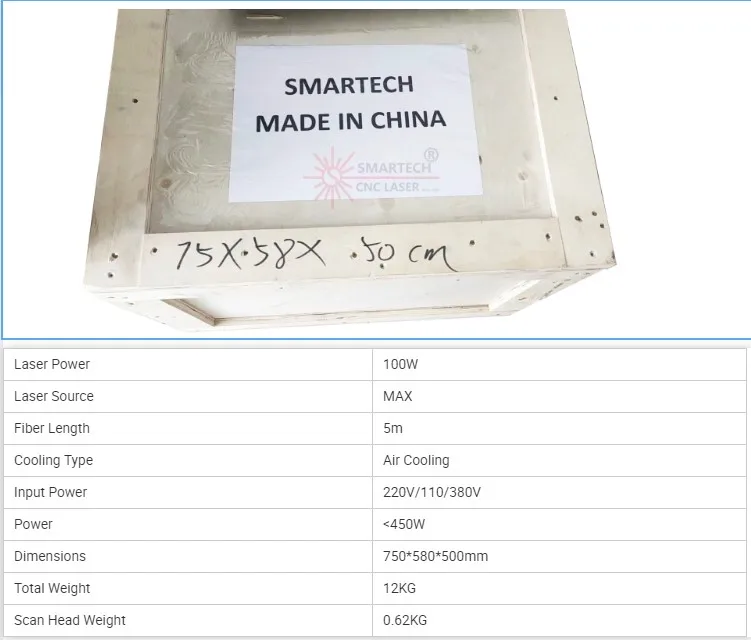

Laser Cleaning Machine Package Before Delivery

Laser cleaning technology is the process of using laser beam to irradiate the surface of the workpiece to peel off or vaporize the dirt and rust coating on the surface, so as to clean the surface of the workpiece to achieve the purpose. What is recognized is the thermal effect and vibration effect of laser.

Laser cleaning as a new cleaning technology, laser cleaning has many advantages, such as environmental protection, high efficiency and so on. It is one of the main development directions of laser technology, and has a wide application prospect. It has been well applied in aerospace, shipbuilding, rail transit, automobile manufacturing, steel manufacturing, electronic industry, medical treatment and cultural relic restoration.

Advantages of laser cleaning

Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid solid strong impact cleaning and high frequency ultrasonic cleaning, laser cleaning has obvious advantages.

1.Laser cleaning is a kind of "green" cleaning method. It doesn't need any chemical agents and cleaning liquid. The waste material is solid powder, small in volume, easy to store and recyclable. It can easily solve the environmental pollution problem caused by chemical cleaning;

2.The traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the object to be

cleaned, which damages the surface of the object or the cleaning medium adheres to the surface of the object to be cleaned, which can not be removed, resulting in secondary pollution;

3. Laser can be transmitted through optical fiber, cooperate with robot hand and robot to realize remote operation conveniently.

It can clean the parts that are not easy to reach by traditional methods, which can ensure the safety of personnel when used in some dangerous places;

4.Laser cleaning can remove all kinds of pollutants on the surface of all kinds of materials, which can not be achieved by

conventional cleaning. Moreover, the pollutants on the material surface can be selectively cleaned without damaging the material surface;

5. High efficiency of laser cleaning and time saving;

6.Although the initial one-time investment of laser cleaning system is high, the cleaning system can be used stably for a long time with low operating cost. More importantly, it can realize automatic operation conveniently.

FAQ

Q1:.How we choose the power?

A:Let us know what do you want to clean,Rust/oil/paint/oxide.... , and the thickness ,then we can recommand suit power to you.

Q2:Can you test samples for us?

A:Yes, of course. You can send samples or if we have similar samples , we can test it it and send vidoe for you

to check and send the samples back to you

Q3:Can we visit your company?

A:Yes, of course. Warmly welcome~

Q4:Are you factory?

A:Yes,We are factory.

Q5:Can you change the language in software for us ?

A:Yes,of course.

Q6:Do you have overseas after-sales ?

A:Yes,we have, if you want overseas after-sales, let us know first.

any more questions , be free ~

Jinan Smart Technology Co.,ltd (SMARTECH)

100 meters south of fengqi,Shizhong District,Jinan,Shandong China

Whats App:+0086-15064149218

Official Website:

https://www.jncnclaser.com

https://smartcnc.en.alibaba.com/

https://www.facebook.com/smartcnclaser/

https://www.instagram.com/smartcnclasermachine/

https://twitter.com/SmartCNCLaser

https://www.youtube.com/channel/UC_KHu77gwdXcP0xStzYIPAg

https://www.pinterest.com/chinasmartech/

To Improve Your Business Is Our Business Goal!——21 Years' Manufacturing experience!

Scope of application of industril laser cleaning device

Small area or local cleaning applications, paint removal, red rust removal, black rust removal, oil removal; stainless steel and aluminum alloy

and other alloys before and after welding; removal of copper oxide, zirconia, etc., metal surface wool and surface wiredrawing.

Laser Cleaning Machine Package Before Delivery

Laser cleaning technology is the process of using laser beam to irradiate the surface of the workpiece to peel off or vaporize the dirt and rust coating on the surface, so as to clean the surface of the workpiece to achieve the purpose. What is recognized is the thermal effect and vibration effect of laser.

Laser cleaning as a new cleaning technology, laser cleaning has many advantages, such as environmental protection, high efficiency and so on. It is one of the main development directions of laser technology, and has a wide application prospect. It has been well applied in aerospace, shipbuilding, rail transit, automobile manufacturing, steel manufacturing, electronic industry, medical treatment and cultural relic restoration.

Advantages of laser cleaning

Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid solid strong impact cleaning and high frequency ultrasonic cleaning, laser cleaning has obvious advantages.

1.Laser cleaning is a kind of "green" cleaning method. It doesn't need any chemical agents and cleaning liquid. The waste material is solid powder, small in volume, easy to store and recyclable. It can easily solve the environmental pollution problem caused by chemical cleaning;

2.The traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the object to be

cleaned, which damages the surface of the object or the cleaning medium adheres to the surface of the object to be cleaned, which can not be removed, resulting in secondary pollution;

3. Laser can be transmitted through optical fiber, cooperate with robot hand and robot to realize remote operation conveniently.

It can clean the parts that are not easy to reach by traditional methods, which can ensure the safety of personnel when used in some dangerous places;

4.Laser cleaning can remove all kinds of pollutants on the surface of all kinds of materials, which can not be achieved by

conventional cleaning. Moreover, the pollutants on the material surface can be selectively cleaned without damaging the material surface;

5. High efficiency of laser cleaning and time saving;

6.Although the initial one-time investment of laser cleaning system is high, the cleaning system can be used stably for a long time with low operating cost. More importantly, it can realize automatic operation conveniently.

FAQ

Q1:.How we choose the power?

A:Let us know what do you want to clean,Rust/oil/paint/oxide.... , and the thickness ,then we can recommand suit power to you.

Q2:Can you test samples for us?

A:Yes, of course. You can send samples or if we have similar samples , we can test it it and send vidoe for you

to check and send the samples back to you

Q3:Can we visit your company?

A:Yes, of course. Warmly welcome~

Q4:Are you factory?

A:Yes,We are factory.

Q5:Can you change the language in software for us ?

A:Yes,of course.

Q6:Do you have overseas after-sales ?

A:Yes,we have, if you want overseas after-sales, let us know first.

any more questions , be free ~

Jinan Smart Technology Co.,ltd (SMARTECH)

100 meters south of fengqi,Shizhong District,Jinan,Shandong China

Whats App:+0086-15064149218

Official Website:

https://www.jncnclaser.com

https://smartcnc.en.alibaba.com/

https://www.facebook.com/smartcnclaser/

https://www.instagram.com/smartcnclasermachine/

https://twitter.com/SmartCNCLaser

https://www.youtube.com/channel/UC_KHu77gwdXcP0xStzYIPAg

https://www.pinterest.com/chinasmartech/

To Improve Your Business Is Our Business Goal!——21 Years' Manufacturing experience!