COMMODITY&DESCRIPTION

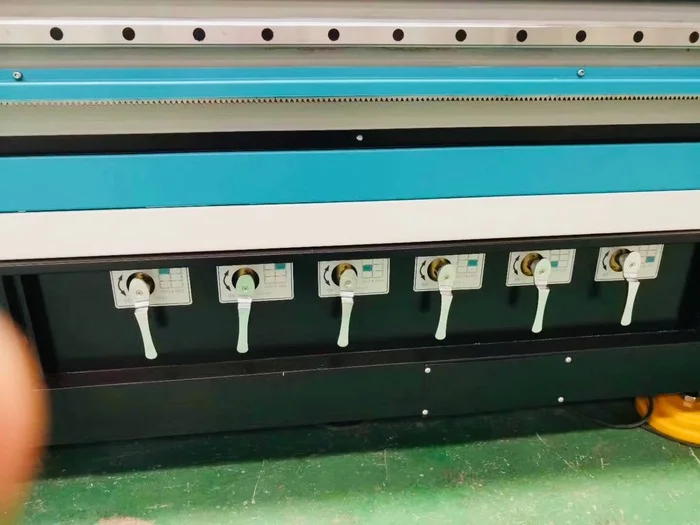

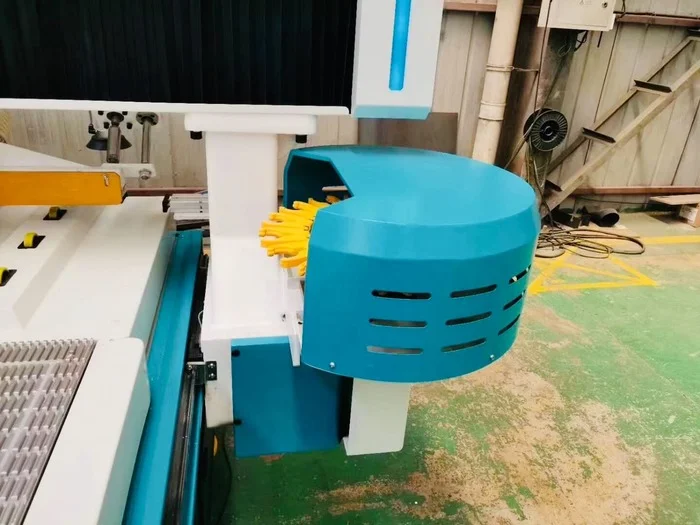

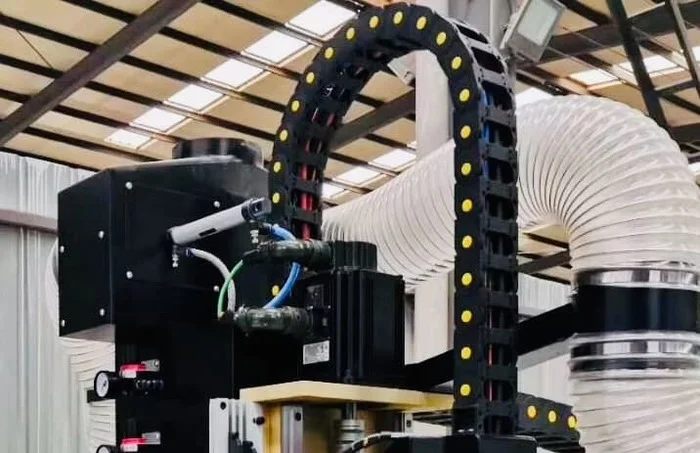

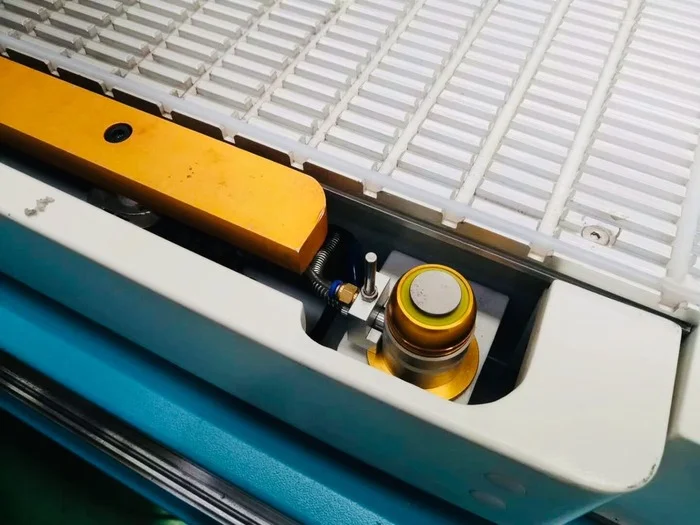

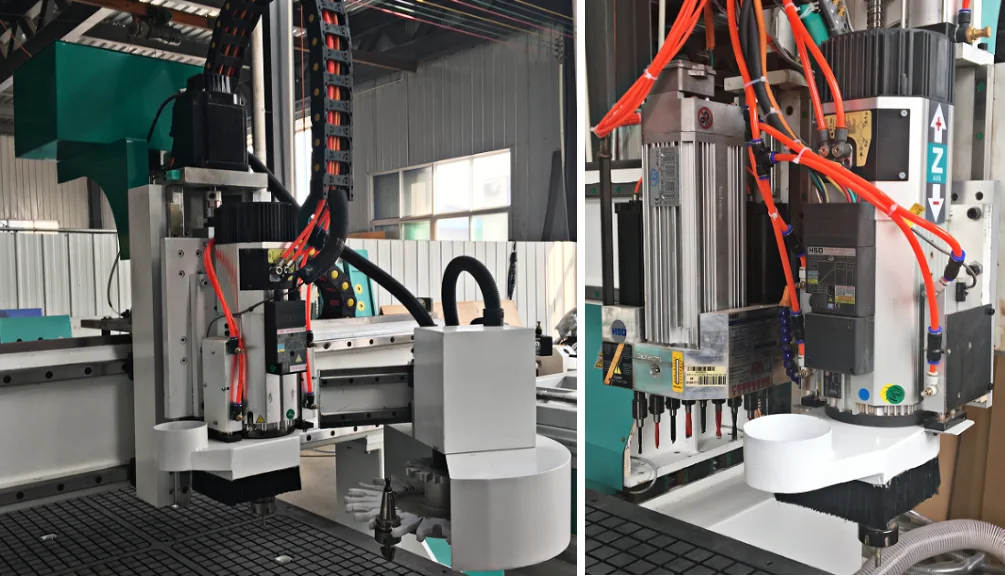

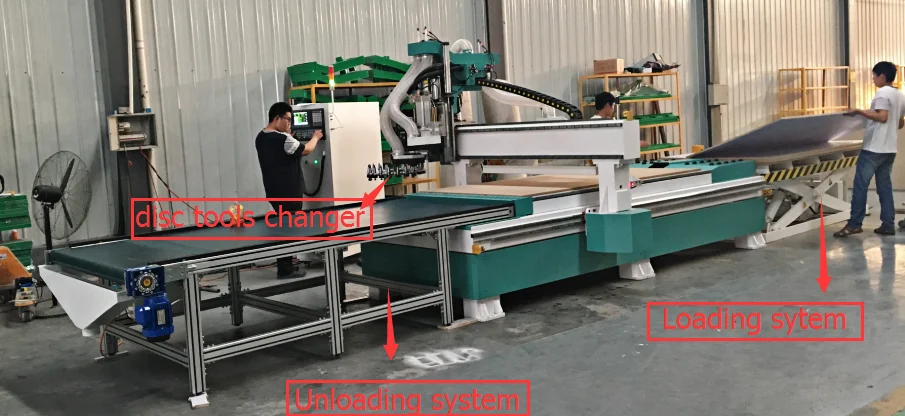

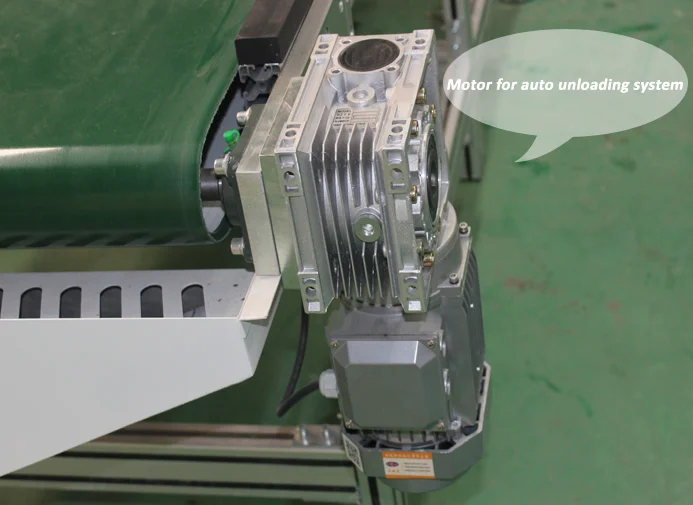

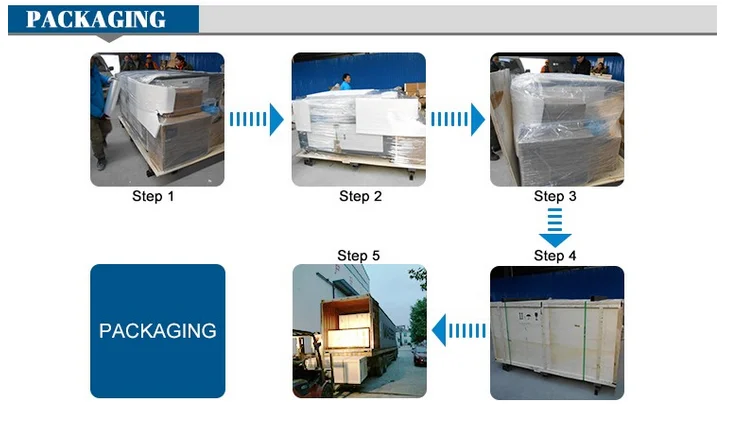

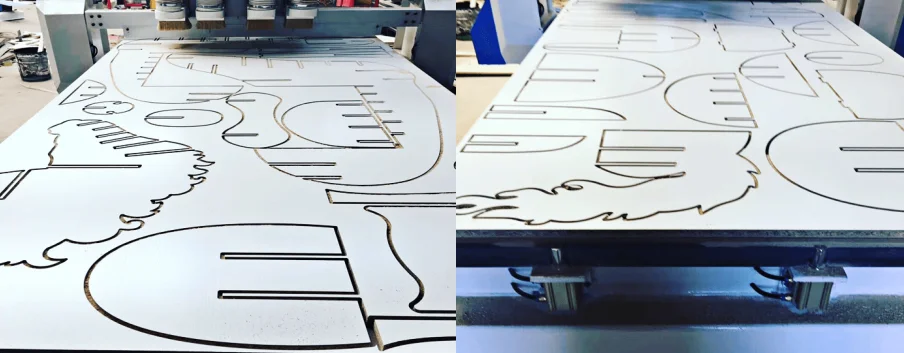

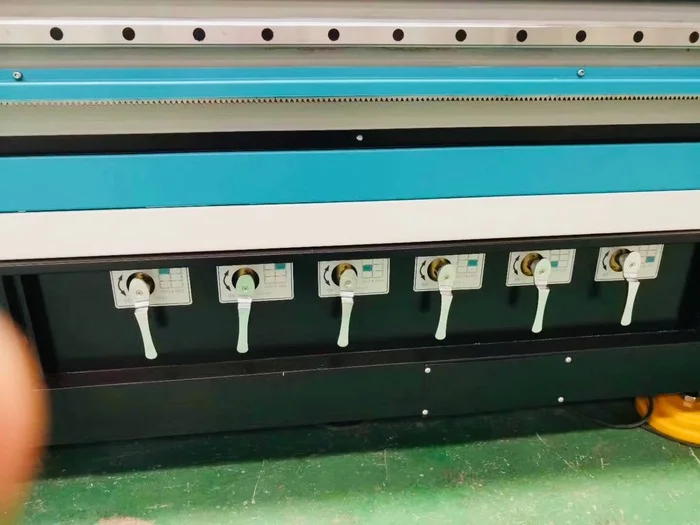

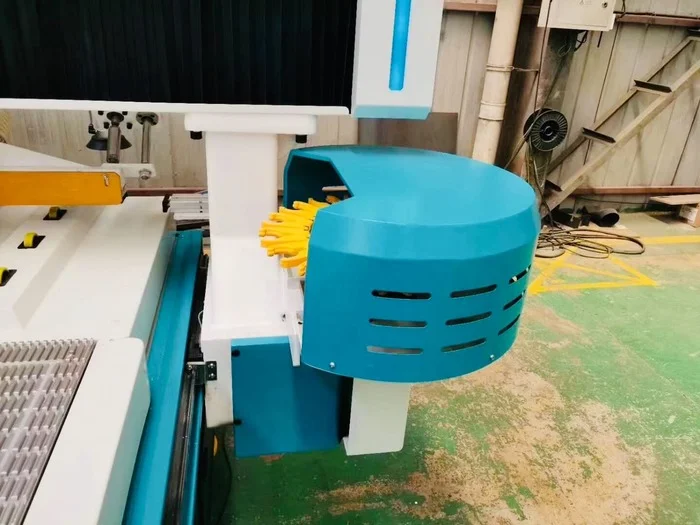

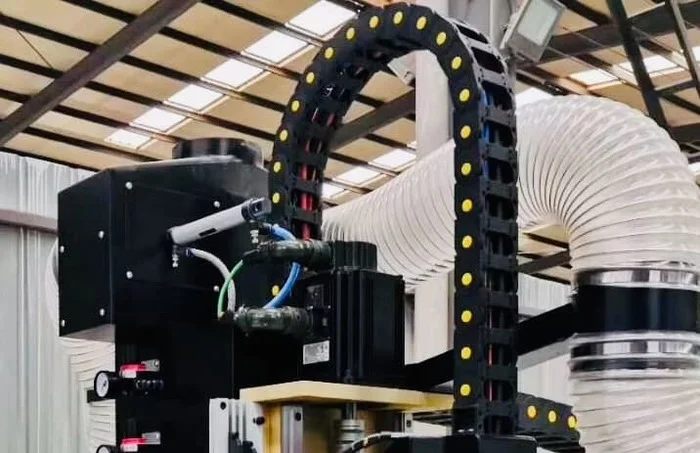

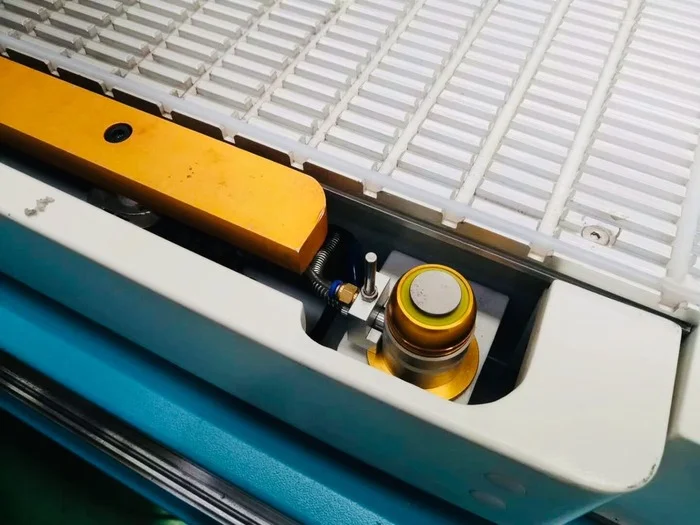

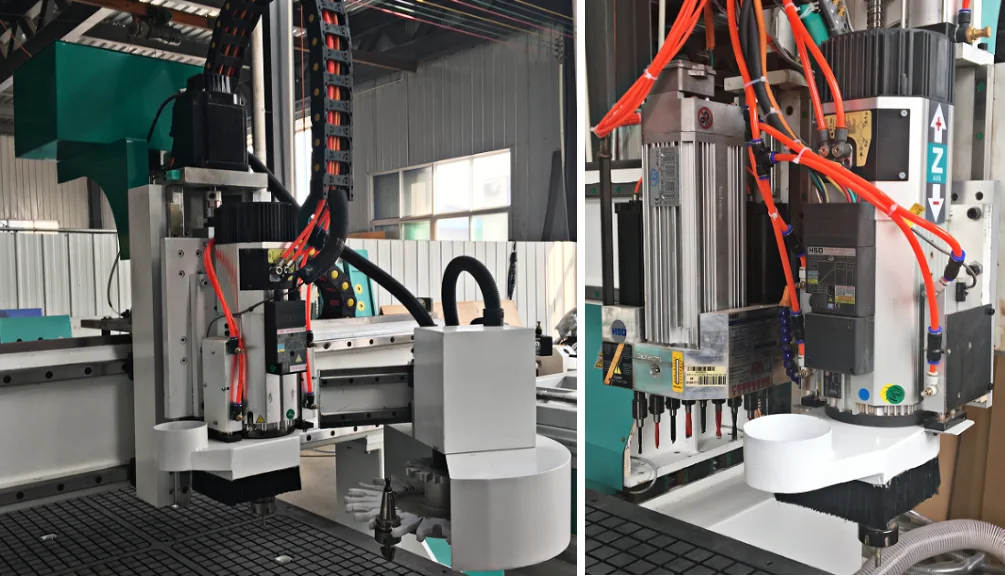

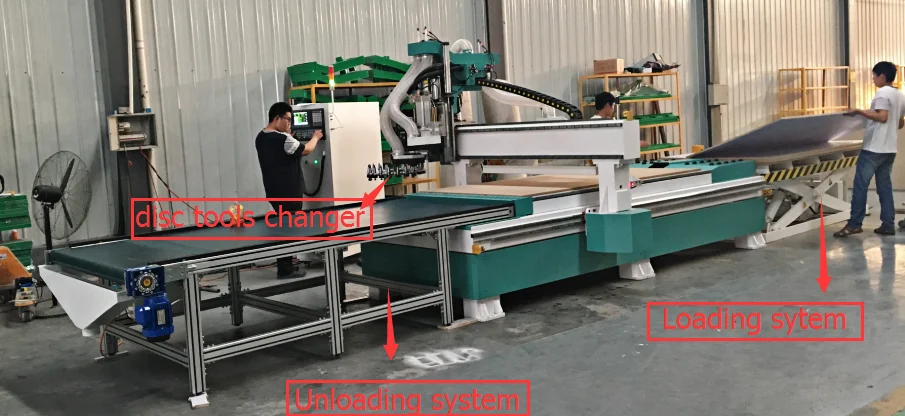

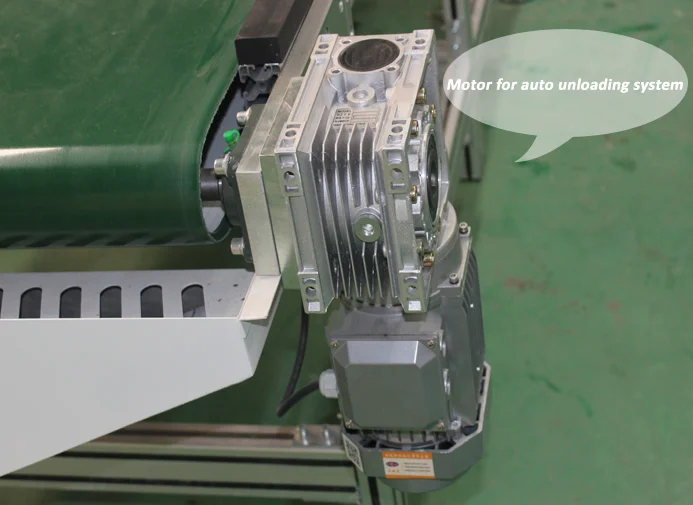

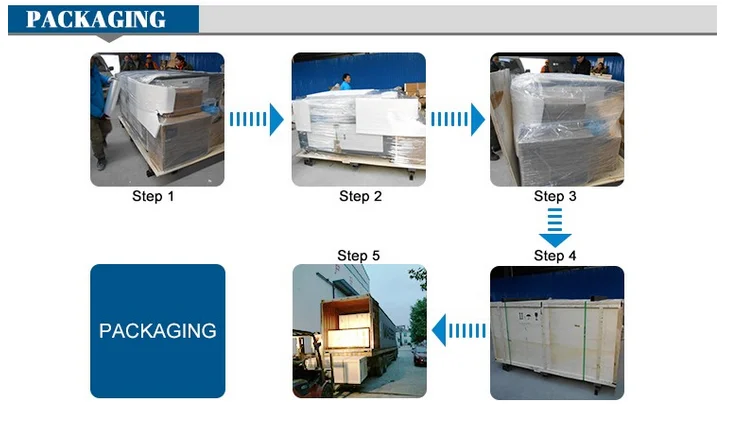

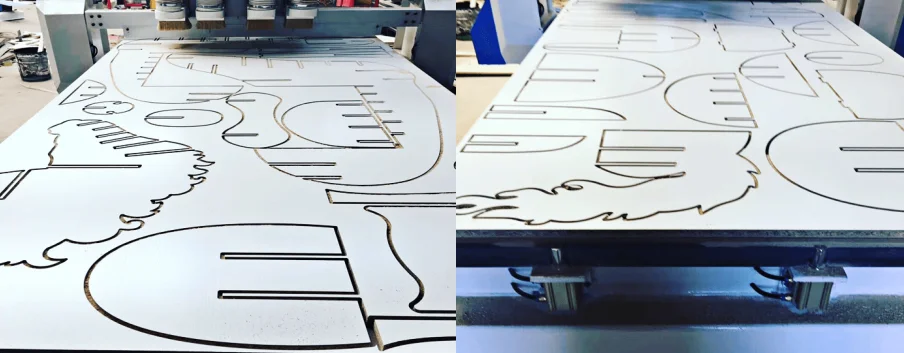

SA Series ATC 2040 Model CNC Router (CE standard) #Working area:2000x4000*200mm #9.0KW hsd italy air cooling automatic tools changer Spindle #10 magazine tools holder #Japan shimpo reducer #Origin point for table protection. #Safety sensor for option(protect human safety) #Auto feeding and pushing system (for materials loading unloading) #Gear-wheel transmission imported from Taiwan for X,Y,ball screw transmission for z axis #1.5 M high precision Herion gear rack pinions. #Rack and Rails 30mm With full anti dust professional structure.(one of the features.) #Yaskawa servo motor and driver FOR X Y Z AXIS. 850W with brakes #Vacuum pump 5.5KW*2 pieces #delta inverter #Auto lubricating system for machine maintenance #Automatic tool sensor+Hand wheel+POP PIN #6 zones vacuum table+Cast Aluminium #Dust collector with dust hood, pipeline switch #Pressure roller #Unloading pusher # mist sprayer fir tool cooling #Taiwan Syntec 60WA #Strong Seamless Steel frame #3 Years’ warranty,Lifetime after sale service #On-site technicians are available. #Famous brand CHNT and schneider electrical components, high flexible shielded cable Optional parts: Auto loading unloading system