| Availability: | |

|---|---|

Smart-3200MM

SMARTECH

Technical description

1). Product detailed configuration

No. | Item | numerical value | unit | |

1 | Nominal pressure | 100 | KN | |

2 | Workbench length | 3200 | mm | |

3 | distance between columns | 2500 | mm | |

4 | throat depth | 350 | mm | |

5 | Slider stroke | 180 | mm | |

6 | maximum opening height | 580 | mm | |

7 | Slide stroke speed | Get off quickly | 120 | mm/s |

Work progresses | 9 | mm/s | ||

Return trip | 100 | mm/s | ||

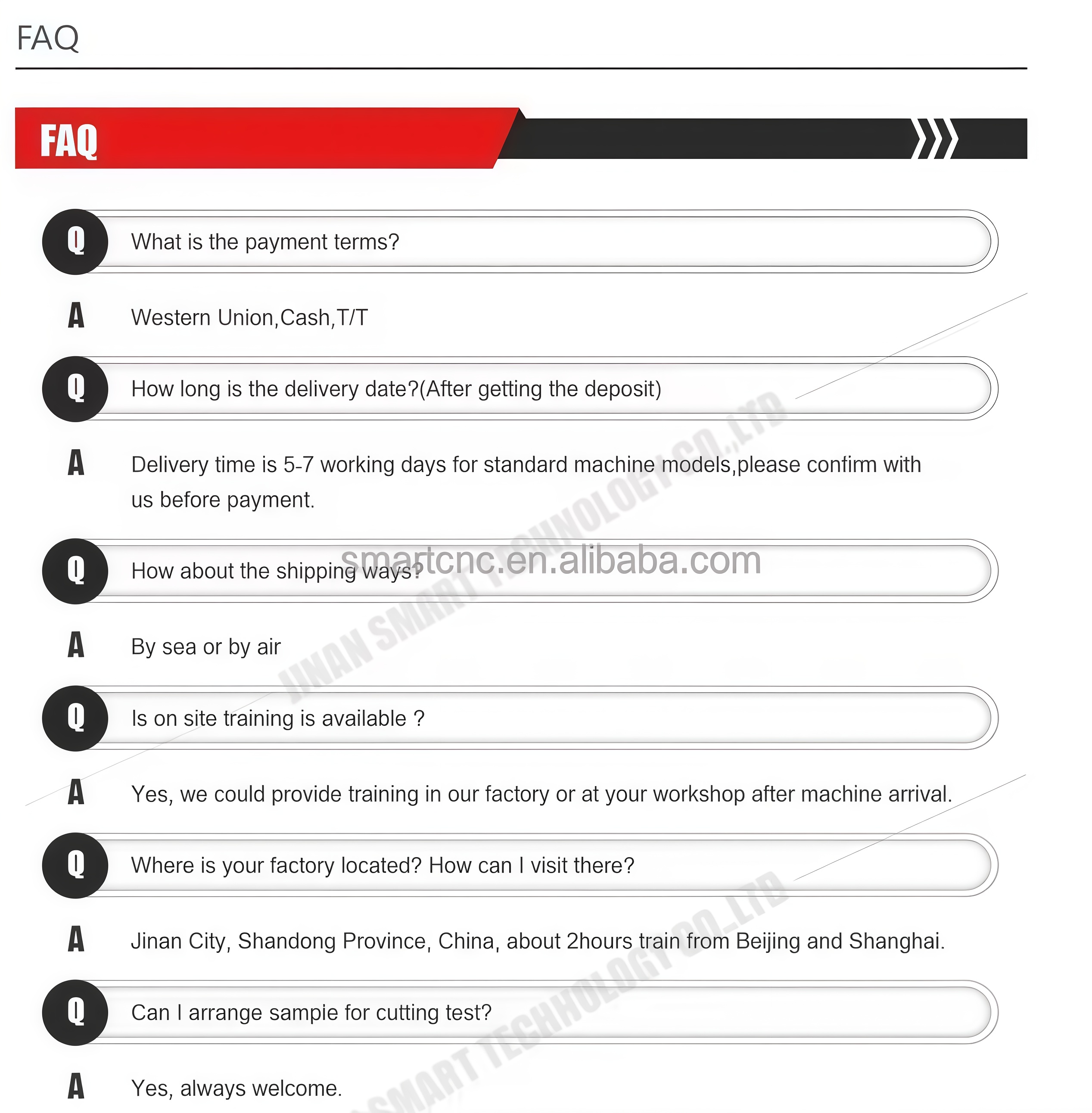

8 | main motor power | 7.5-6 | kw | |

2) Main product parameters

project | unit | Accuracy requirements |

1. Slider Y1, Y2 axis accuracy | ||

Repeat accuracy | mm | ≤0.05 |

positioning accuracy | mm | ≤0.08 |

2. Back gauge X-axis working accuracy | ||

Repeat accuracy | mm | ≤0.05 |

positioning accuracy | mm | ≤0.08 |

3. Machine tool working accuracy | ||

Test piece bending angle accuracy | mm | +0.5°mm/3000mm |

Test piece straightness accuracy | mm | ±0.15/1000 mm |

The system has the following characteristics:

1. Electro-hydraulic servo valve group drive, compact structure, strong sealing performance, high synchronization accuracy and long life

2. External large-diameter liquid filling valve, high speed and low loss.

3. The internal gear high-pressure pump can withstand high pressure and has low noise.

4. The cylinder seal adopts sealing components, which has low wear and no leakage.

5. The hydraulic system has overload overflow safety protection.

6. The oil level has a clear and intuitive display.

7. High-precision guidance system, position measurement system and hydraulic balancing function can meet the needs of full-length processing.

8. The machine tool can work continuously under rated load. The hydraulic system has no leakage and is continuously stable and has high precision.

9. The hydraulic oil cooling circulation system should be able to meet the requirements of the equipment’s working environment.

Machine parts

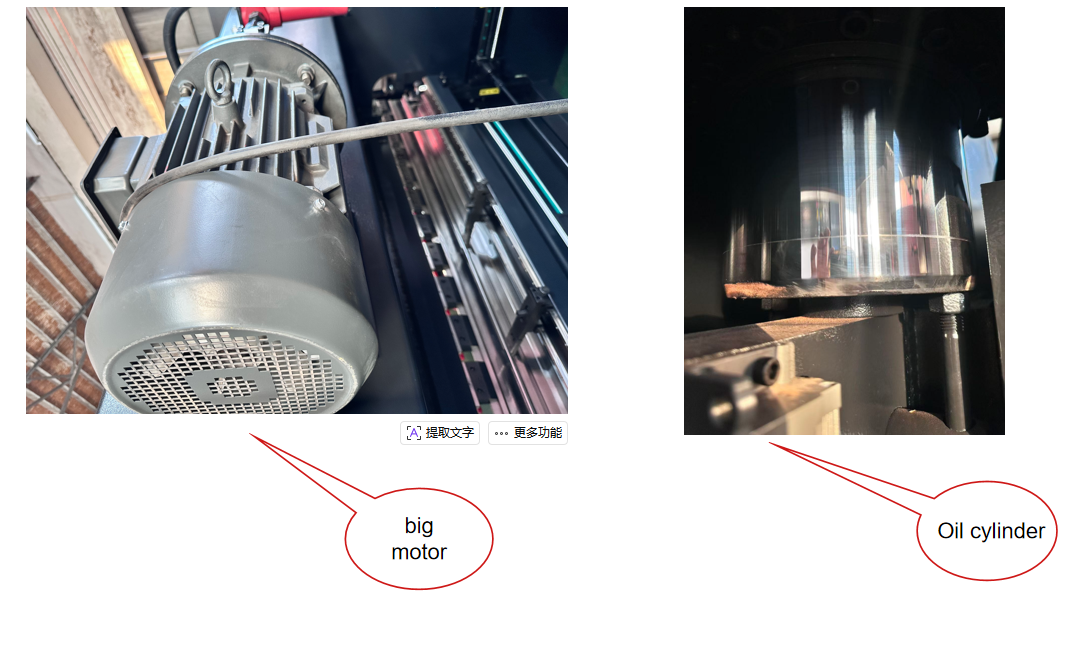

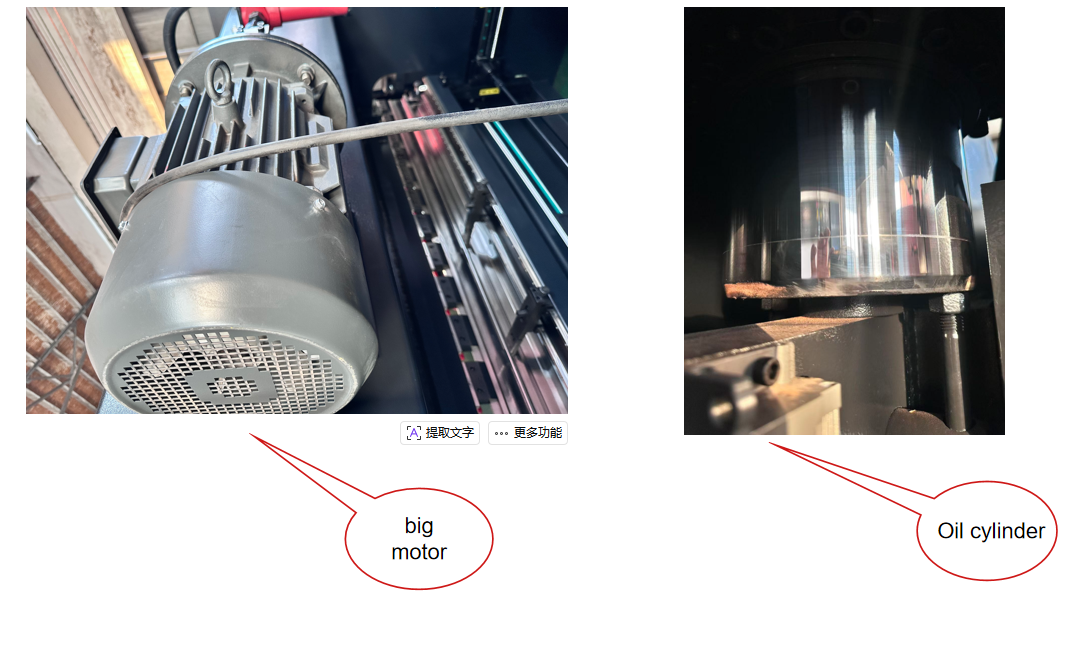

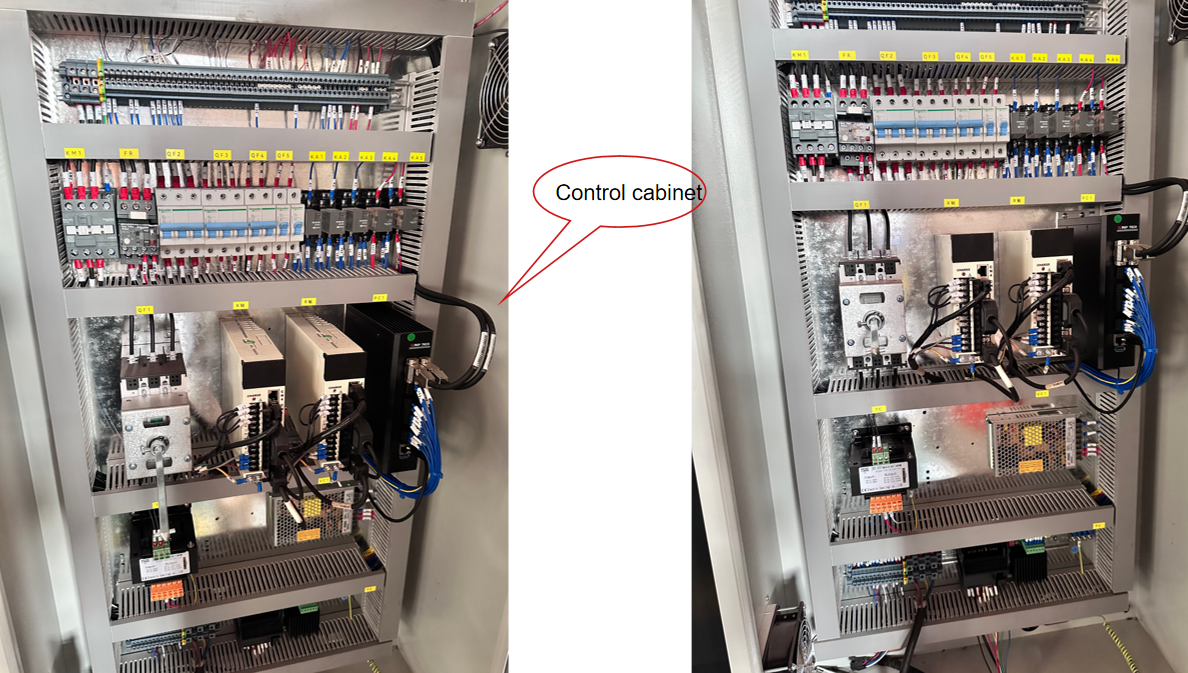

Machine Tool Structure

This machine is assembled from a frame, slider, workbench,

oil cylinder, hydraulic proportional servo system,

position detection system, numerical control system and electrical system.

The transmission structure of this machine tool

is an upward-moving design;

1. The mechanical structure of this machine tool mainly consists of the frame, workbench, slider, main cylinder, and back gauge. Perfect design and manufacturing technology can effectively ensure the manufacturing and use accuracy of machine tools.

2. The rack adopts frame structure, the all-steel overall welded structure eliminates internal stress through

normalizing and high-frequency vibration aging to ensure the overall accuracy of the machine tool, has excellent stiffness, and has excellent anti-twisting and anti-tilt capabilities. The thickened worktable and slider make the whole machine highly rigid, so the slider and worktable deform very little during bending, and the workpiece has excellent straightness and angle consistency.

●Use a large floor-standing boring and milling machine to perform precision processing using the overall one-time processing method., to ensure the overall processing accuracy of the machine tool.

●The up and down movement of the slider is controlled by two oil cylinders. The slide synchronization mechanism adopts CNC electro-hydraulic servo control synchronization, which is stable and reliable.

●showThe current position and target position of Y1 axis, Y2 axis, X axis and R axis.

●There are adjustment, semi-automatic and fully automatic modes.

●The backgauge device has the functions of automatically retracting materials and delaying action.

●The backgauge device adopts Mitsubishi servo motor and Taiwan Intime ball screw and linear guide rail.X axis Transmission positioning accuracy and repeat positioning accuracy are reliably guaranteed.

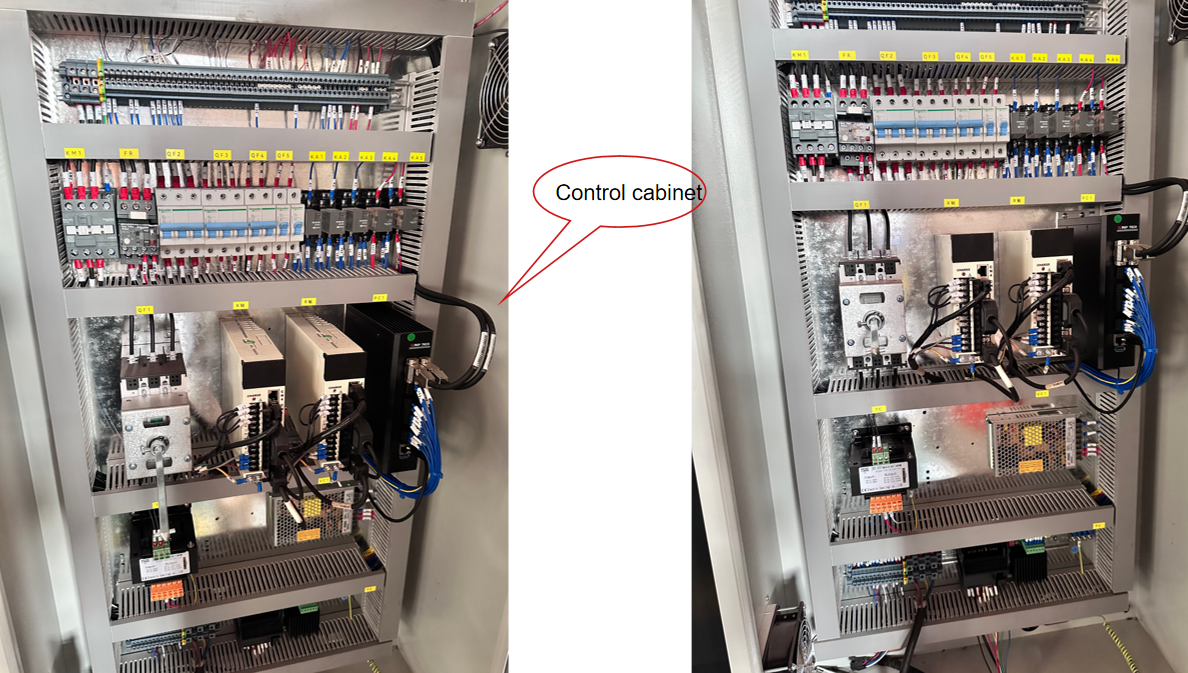

CNC system

CNC system

DE15 electro-hydraulic servo CNC system features and functions:

The DE15 bending machine CNC system provides users with a friendly operation interface, high-efficiency programming methods, and proud integration of stability, which will greatly improve the working efficiency of the CNC bending machine.

The latest graphical programming technology inherits the traditional programming advantages of DE15 and displays workpieces, molds and machine tools in true proportions.

The CNC system has automatic calculation of the bending process, workpiece interference detection and self-learning database. The use of the database will greatly improve the bending accuracy. Use more efficient algorithms to optimize the entireThe Y-axis working cycle shortens the cycle of the Y-axis cycle, improves the working efficiency of the machine tool, and makes the Y-axis adjustment and control more convenient.

Windows The network function is easily integrated with the factory network, allowing the CNC system to exchange data with computers anywhere on the network and access product programs.

About us

Related Production Line Machines You Might Be Interested In:

Technical description

1). Product detailed configuration

No. | Item | numerical value | unit | |

1 | Nominal pressure | 100 | KN | |

2 | Workbench length | 3200 | mm | |

3 | distance between columns | 2500 | mm | |

4 | throat depth | 350 | mm | |

5 | Slider stroke | 180 | mm | |

6 | maximum opening height | 580 | mm | |

7 | Slide stroke speed | Get off quickly | 120 | mm/s |

Work progresses | 9 | mm/s | ||

Return trip | 100 | mm/s | ||

8 | main motor power | 7.5-6 | kw | |

2) Main product parameters

project | unit | Accuracy requirements |

1. Slider Y1, Y2 axis accuracy | ||

Repeat accuracy | mm | ≤0.05 |

positioning accuracy | mm | ≤0.08 |

2. Back gauge X-axis working accuracy | ||

Repeat accuracy | mm | ≤0.05 |

positioning accuracy | mm | ≤0.08 |

3. Machine tool working accuracy | ||

Test piece bending angle accuracy | mm | +0.5°mm/3000mm |

Test piece straightness accuracy | mm | ±0.15/1000 mm |

The system has the following characteristics:

1. Electro-hydraulic servo valve group drive, compact structure, strong sealing performance, high synchronization accuracy and long life

2. External large-diameter liquid filling valve, high speed and low loss.

3. The internal gear high-pressure pump can withstand high pressure and has low noise.

4. The cylinder seal adopts sealing components, which has low wear and no leakage.

5. The hydraulic system has overload overflow safety protection.

6. The oil level has a clear and intuitive display.

7. High-precision guidance system, position measurement system and hydraulic balancing function can meet the needs of full-length processing.

8. The machine tool can work continuously under rated load. The hydraulic system has no leakage and is continuously stable and has high precision.

9. The hydraulic oil cooling circulation system should be able to meet the requirements of the equipment’s working environment.

Machine parts

Machine Tool Structure

This machine is assembled from a frame, slider, workbench,

oil cylinder, hydraulic proportional servo system,

position detection system, numerical control system and electrical system.

The transmission structure of this machine tool

is an upward-moving design;

1. The mechanical structure of this machine tool mainly consists of the frame, workbench, slider, main cylinder, and back gauge. Perfect design and manufacturing technology can effectively ensure the manufacturing and use accuracy of machine tools.

2. The rack adopts frame structure, the all-steel overall welded structure eliminates internal stress through

normalizing and high-frequency vibration aging to ensure the overall accuracy of the machine tool, has excellent stiffness, and has excellent anti-twisting and anti-tilt capabilities. The thickened worktable and slider make the whole machine highly rigid, so the slider and worktable deform very little during bending, and the workpiece has excellent straightness and angle consistency.

●Use a large floor-standing boring and milling machine to perform precision processing using the overall one-time processing method., to ensure the overall processing accuracy of the machine tool.

●The up and down movement of the slider is controlled by two oil cylinders. The slide synchronization mechanism adopts CNC electro-hydraulic servo control synchronization, which is stable and reliable.

●showThe current position and target position of Y1 axis, Y2 axis, X axis and R axis.

●There are adjustment, semi-automatic and fully automatic modes.

●The backgauge device has the functions of automatically retracting materials and delaying action.

●The backgauge device adopts Mitsubishi servo motor and Taiwan Intime ball screw and linear guide rail.X axis Transmission positioning accuracy and repeat positioning accuracy are reliably guaranteed.

CNC system

CNC system

DE15 electro-hydraulic servo CNC system features and functions:

The DE15 bending machine CNC system provides users with a friendly operation interface, high-efficiency programming methods, and proud integration of stability, which will greatly improve the working efficiency of the CNC bending machine.

The latest graphical programming technology inherits the traditional programming advantages of DE15 and displays workpieces, molds and machine tools in true proportions.

The CNC system has automatic calculation of the bending process, workpiece interference detection and self-learning database. The use of the database will greatly improve the bending accuracy. Use more efficient algorithms to optimize the entireThe Y-axis working cycle shortens the cycle of the Y-axis cycle, improves the working efficiency of the machine tool, and makes the Y-axis adjustment and control more convenient.

Windows The network function is easily integrated with the factory network, allowing the CNC system to exchange data with computers anywhere on the network and access product programs.

About us

Related Production Line Machines You Might Be Interested In: