| Availability: | |

|---|---|

Smart -P Series

SMARTECH

800w/1200w/1500w/2000w

Performance characteristics

●Adapt for various metal materials, Carbon steel, stainless steel, high-strength steel, aluminum, copper and alloy materials;

●The light can be emitted continuously or pulsed, not only for thermal conductivity, but also for continuous deep penetration. It can realize spot welding, butt welding, stitch welding, sealing welding, seam welding, cleaning,cutting.

●Adopt continuous Fiber laser, excellent beam quality, maintenance-free, photoelectric conversion efficiency is greater than 25%, and the service life of the pump source is greater than 100,000 hours;

●Fast processing speed;

●Small thermal deformation and heat affected zone (suitable for processing high melting point, high hardness, special materials);

●It can process parts with complex shapes and small parts, and can also be processed in vacuum;

●and Robotic arm and other automated institutions Combined, the processing can be automated;

●Can realize filler wire welding,Due to advanced processimethods, existproduct structures and materials can be improved.

●All-aluminum exterior, lightweight

Technical Data

Laser type | Continuous fiber laser | |||

Rated output power | 800W | 1200w | 1500w | 2000w |

Applicable power | ≤800W ≤1200W ≤1500W | |||

Laser center wavelength | 1080nm (±10nm) | |||

Cooling method | Air cooling | |||

Maximum modulation frequency | 50kHz | |||

Power instability | <3% | |||

Fiber output interface | QBH | |||

Indicating system | Red light | |||

Supply voltage (V) | 220V±5% AC 50/60Hz | |||

Torch cable length | 10m 10m | |||

Torch type | 3 In 1 laser head | |||

Collimating mirror | D16*T5-F50 | |||

Focus mirror size (mm) | D20 * T4.5-F150 | |||

Wire feed diameter | 0.8, 1.0, 1.2, 1.6,2,2.5,3 | |||

Protective mirror size (mm) | D18xT2 |

Protective gas method | Coaxial protection |

Adjustable weld width | 0~6mm |

product structure | Portable |

Product size L*D*H | 560*340*580mm |

product weight | 53kg |

Working temperature | 10~40℃ |

Working environment humidity | <70% |

Recommended air flow | 10~15L/min (20℃ 0.15MPa) |

Focus vertical adjustment range | ±10mm |

Compatible laser | The beam is collimated to φ≤10mm |

Machine parts

Control System

Laser Head

1.Comfortable Grip

Ergonomically designed for a comfortable grip, its compact structure makes it lightweight and portable.

2.Quick Replacement

The focusing lens and protective lens feature an integrated drawer design, allowing for quick and easy

replacement and maintenance, ensuring the continuity and efficiency of the welding process.

3.Intelligent Monitoring

Equipped with self-developed control software, it monitors key parameters such as machine temperature,

power status, motor operation, and laser output in real time, ensuring stable operation and improving

welding accuracy and efficiency.

4.Convenient Operation

Features a one-button wire feed/stop switch for easy switching, greatly enhancing operational convenience

and work efficiency.

Interface Type | QCS |

Laser Incident Method | Coaxial |

Laser Power | ≤2KW |

Laser Wavelength Range | 1070±20nm |

Weight | 0.53kg |

Collimation Focal Length | 60mm |

Focusing Focal Length | 150mm |

Adjustable Amplitude | 0-6mm |

Protective Gas | Nitrogen |

Wiring Diagram

Laser Power Source

Laser Power Source

Electrical parts

Flexible Optical Fiber & Nozzles

Welded aluminum accessories

Processed samples

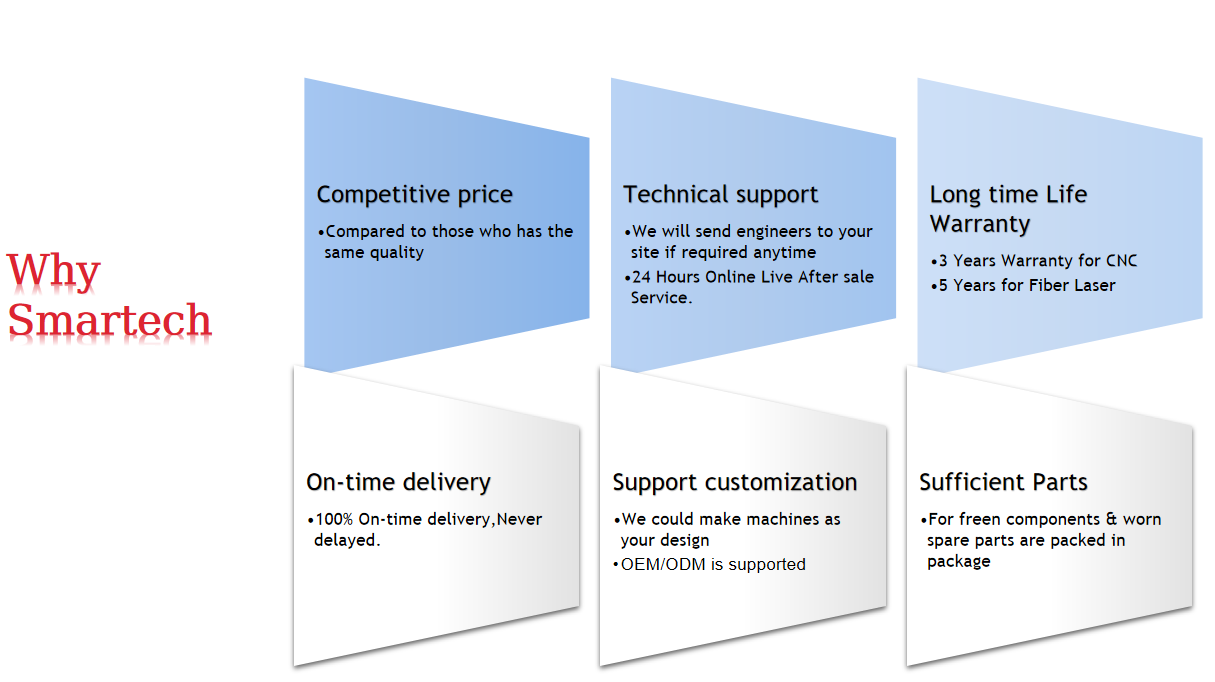

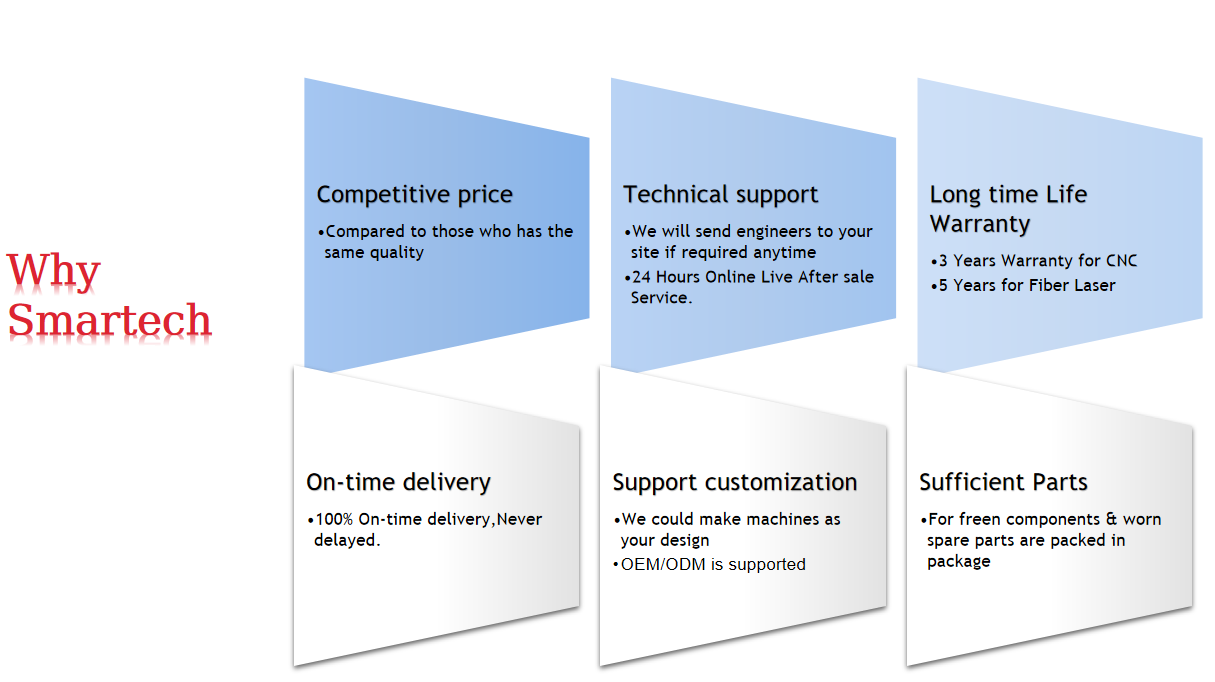

About us

Related Production Line Machines You Might Be Interested In:

Performance characteristics

●Adapt for various metal materials, Carbon steel, stainless steel, high-strength steel, aluminum, copper and alloy materials;

●The light can be emitted continuously or pulsed, not only for thermal conductivity, but also for continuous deep penetration. It can realize spot welding, butt welding, stitch welding, sealing welding, seam welding, cleaning,cutting.

●Adopt continuous Fiber laser, excellent beam quality, maintenance-free, photoelectric conversion efficiency is greater than 25%, and the service life of the pump source is greater than 100,000 hours;

●Fast processing speed;

●Small thermal deformation and heat affected zone (suitable for processing high melting point, high hardness, special materials);

●It can process parts with complex shapes and small parts, and can also be processed in vacuum;

●and Robotic arm and other automated institutions Combined, the processing can be automated;

●Can realize filler wire welding,Due to advanced processimethods, existproduct structures and materials can be improved.

●All-aluminum exterior, lightweight

Technical Data

Laser type | Continuous fiber laser | |||

Rated output power | 800W | 1200w | 1500w | 2000w |

Applicable power | ≤800W ≤1200W ≤1500W | |||

Laser center wavelength | 1080nm (±10nm) | |||

Cooling method | Air cooling | |||

Maximum modulation frequency | 50kHz | |||

Power instability | <3% | |||

Fiber output interface | QBH | |||

Indicating system | Red light | |||

Supply voltage (V) | 220V±5% AC 50/60Hz | |||

Torch cable length | 10m 10m | |||

Torch type | 3 In 1 laser head | |||

Collimating mirror | D16*T5-F50 | |||

Focus mirror size (mm) | D20 * T4.5-F150 | |||

Wire feed diameter | 0.8, 1.0, 1.2, 1.6,2,2.5,3 | |||

Protective mirror size (mm) | D18xT2 |

Protective gas method | Coaxial protection |

Adjustable weld width | 0~6mm |

product structure | Portable |

Product size L*D*H | 560*340*580mm |

product weight | 53kg |

Working temperature | 10~40℃ |

Working environment humidity | <70% |

Recommended air flow | 10~15L/min (20℃ 0.15MPa) |

Focus vertical adjustment range | ±10mm |

Compatible laser | The beam is collimated to φ≤10mm |

Machine parts

Control System

Laser Head

1.Comfortable Grip

Ergonomically designed for a comfortable grip, its compact structure makes it lightweight and portable.

2.Quick Replacement

The focusing lens and protective lens feature an integrated drawer design, allowing for quick and easy

replacement and maintenance, ensuring the continuity and efficiency of the welding process.

3.Intelligent Monitoring

Equipped with self-developed control software, it monitors key parameters such as machine temperature,

power status, motor operation, and laser output in real time, ensuring stable operation and improving

welding accuracy and efficiency.

4.Convenient Operation

Features a one-button wire feed/stop switch for easy switching, greatly enhancing operational convenience

and work efficiency.

Interface Type | QCS |

Laser Incident Method | Coaxial |

Laser Power | ≤2KW |

Laser Wavelength Range | 1070±20nm |

Weight | 0.53kg |

Collimation Focal Length | 60mm |

Focusing Focal Length | 150mm |

Adjustable Amplitude | 0-6mm |

Protective Gas | Nitrogen |

Wiring Diagram

Laser Power Source

Laser Power Source

Electrical parts

Flexible Optical Fiber & Nozzles

Welded aluminum accessories

Processed samples

About us

Related Production Line Machines You Might Be Interested In: