| Availability: | |

|---|---|

laser cleaning machine

SMARTECH

New Product 2021

538*411*685mm

538*411*685mm

100W, 200w, 300w

as your preference

Machine Offer

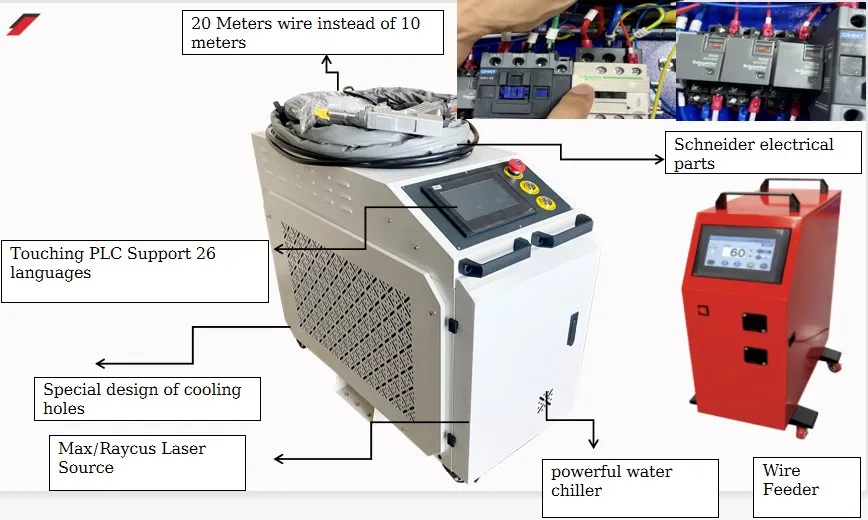

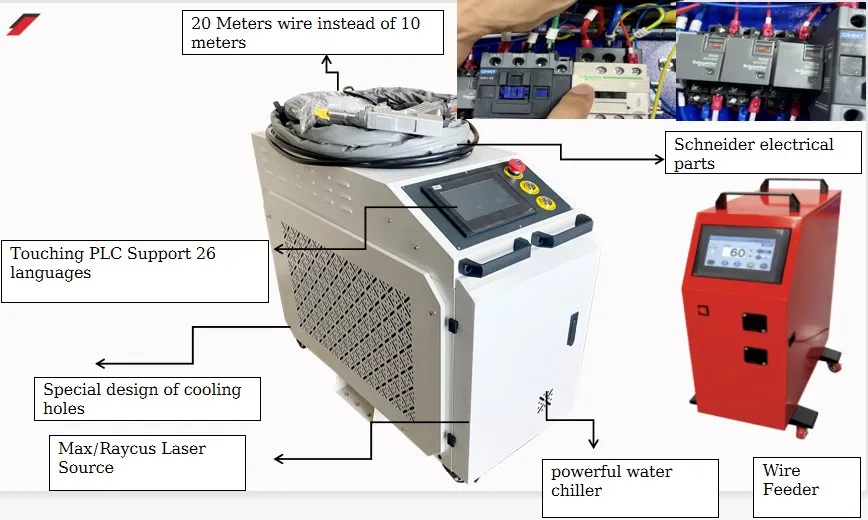

2023 New Desing Model: Smart -P3000W

Main Configuration:

#Fiber laser power 3000W Max/Raycus;

#New Generation laser head SUP 21T

#Double wires feeder

#Schneider parts for electricity

#Fiber cable 20 meters instead of 10;

#Ultra-light weight and compact, it swings the light spot left and right, and has a safety circuit trigger protection function.

#Multi-language operation interface, touch screen control System

#One-piece design,With universal walking casters

#Wire feeding system;

#Hanli/S&A Water Chiller;

#Intelligent control system Wire feeding mechanism

General Information

Features:

1.4 in 1 multifunctional which is more cost effective,your best choice !

2.The internal design is smart, and the good interactive control system expands the tolerance range of the processed parts and the width of the weld seam(range 0-6mm), solves the disadvantage of small light spot, and makes the weld seam better.

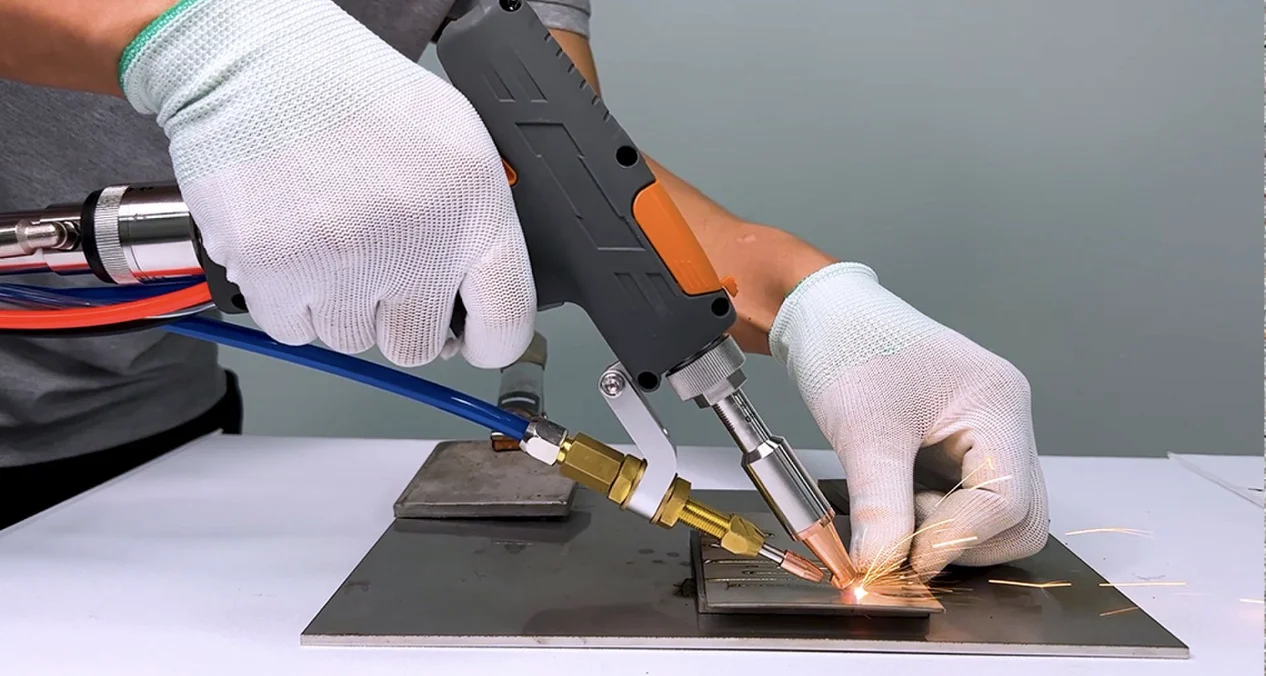

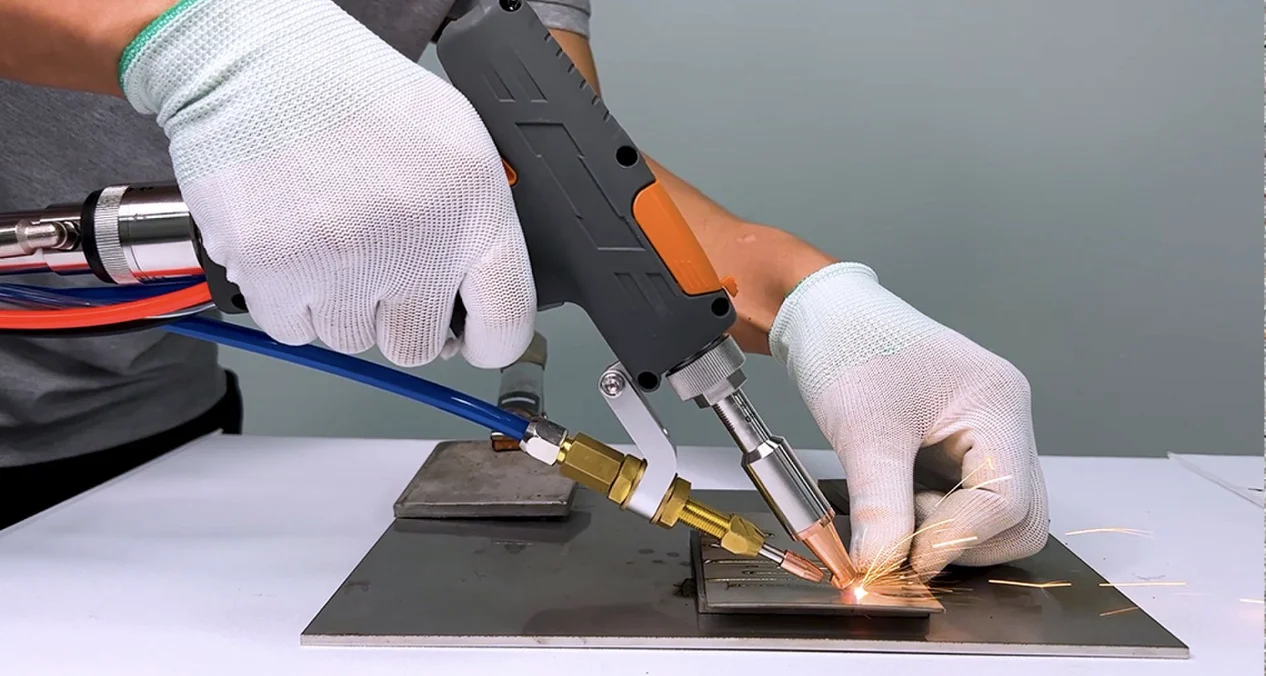

3.Lightweight, using body engineering design method, comfortable grip; easy control with one hand

4.simple operation,Easy to use,no have to be experienced workers,fresh workers are fine.

5.With multiple safety alarms, the light will be automatically locked after the work piece is removed, which is highly safe.

6.Beautiful welding seam, fast speed, no welding marks,not deformation, not blackening, strong welding, no grinding required no need for later polishing,Consumables few.

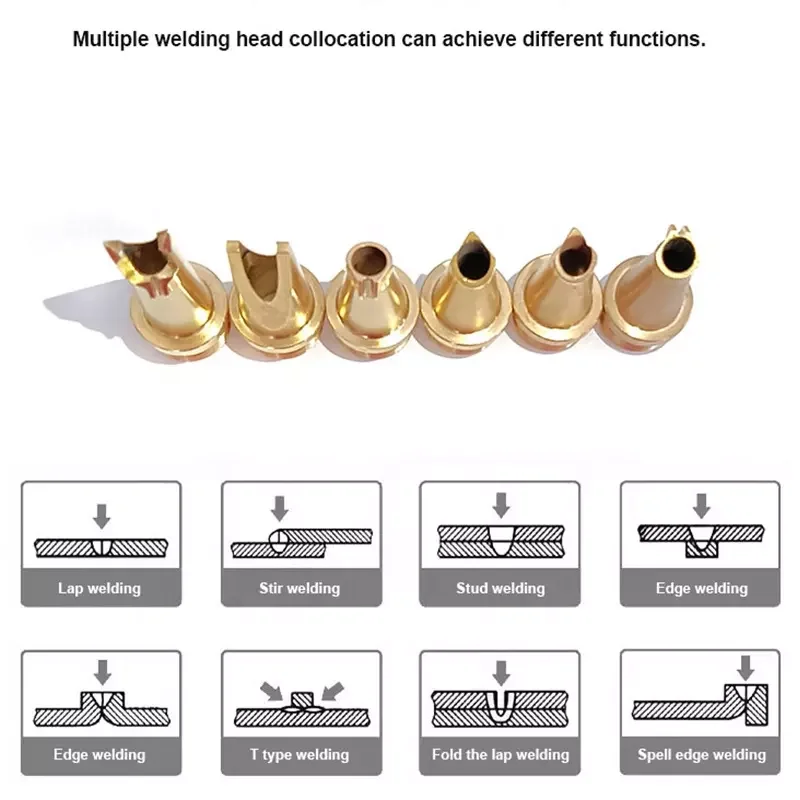

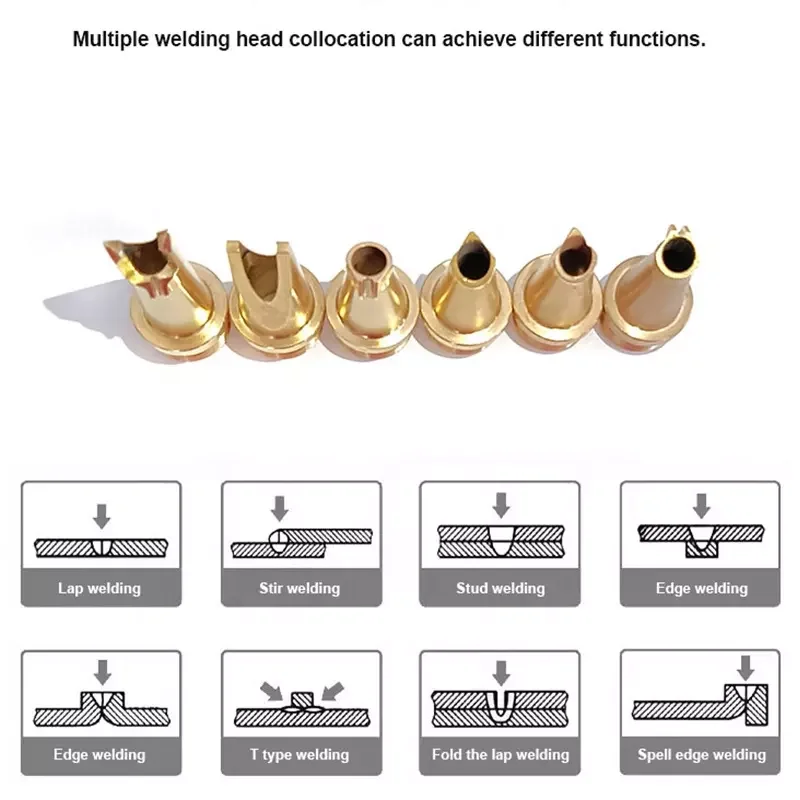

7.Various angle nozzles can be configured to meet the welding needs of different products. 8.Swing welding head can be used for welding at any angle or shape.

Performance characteristics

1.Adapt for various metal materials, Carbon steel, stainless steel, high-strength steel, aluminum, copper and alloy materials;

2.The light can be emitted continuously or pulsed, not only for thermal conductivity, but also for continuous deep penetration. It can realize spot welding, butt welding, stitch welding, sealing welding, seam welding, cleaning,cutting.

3.Adopt continuous Fiber laser, excellent beam quality, maintenance-free, photoelectric conversion efficiency is greater than 25%, and the service life of the pump source is greater than 100,000 hours;

4.Fast processing speed;

5.Small thermal deformation and heat affected zone (suitable for processing high melting point, high hardness, special materials);

6.It can process parts with complex shapes and small parts, and can also be processed in vacuum;

7.and Robotic arm and other automated institutions Combined, the processing can be automated; 8.Can realize filler wire welding,Due to advanced processimethods, existproduct structures and materials can be improved.

Technical data

Model | Smart-W1500 | Smart-W2000 | Smart-W3000 |

Laser type | Continuous fiber laser | ||

Rated output power | 1500W | 2000W | 3000W |

Power adjustment range | 10%~100% | ||

Applicable wavelength | 1070 nm | ||

output method | Continuous/modulation | ||

Maximum modulation frequency | 50kHz | ||

Power instability | <3% | ||

Max air pressure | 15 Bar | ||

Fiber output interface | QBH | ||

Indicating system | Red light | ||

Fiber length | 15mm | ||

Fiber cable length | 20m | ||

Torch type | 4 in 1 laser head | ||

Collimated focal length | 60mm | ||

Focus focal length | 150mm | ||

Spot adjustment range | 0-8mm | ||

Torch weight | 0.7 kg | |||

Protective gas method | Coaxial protection | |||

Adjustable weld width | 0~6mm | |||

Water flow | >15L/min | >25L/min | >30L/min | |

product structure | Standard/ Mini | |||

Product size L*D*H | 1200*600*1300mm/ 680*590*1140mm | |||

product weight | 160kg/150kg | |||

Working temperature | 10~40℃ | |||

Working environment humidity | <70% | |||

Operating Voltage | Single phase 220VAC | Three-phase five-wire 380VACSingle phase 220VAC | ||

Total power | <7kw | <9.5 kw | <16 kw | |

Accessories

Random accessories come with machine | ||

Item | Quantity | Remark |

wrench | 1 pair | GIFT |

barometer | 1 piece | GIFT |

Gloves | 1 pair | GIFT |

Protective lens | 5 slices | GIFT |

Wire | 1 box | GIFT |

Copper mouth | 8 | GIFT |

Product manual | 1 serving | GIFT |

Certificate of conformity | 1 serving | |

Warranty Card | 1 serving | |

Laser manual | 1 serving | |

Laser U Disk Information | 1set | |

Machine - Introduction

Machine - Side View

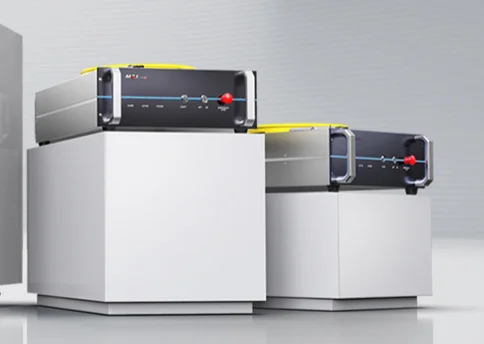

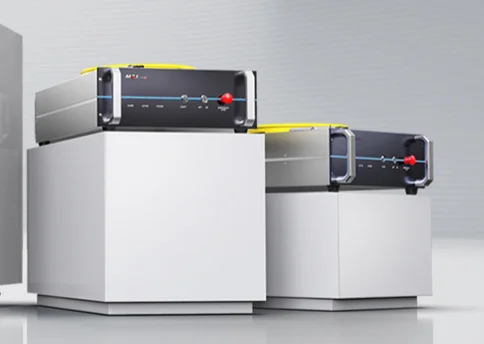

Laser Power Source

Max Laser Source

Raycus Laser Source

Wire Feeding System

Features of laser head:

@1.Easy installation, long life, low noise, low energy consumption;

@2.Small size, small weight, large torque, can be used with long-distance hand-held welding wire feeding;

@3.Wire feeding and welding control are synchronized, the wire feeding is stable and adjustable, suitable for use in different scenarios, and it is easy for the operator to master and quickly get started and skillfully operate.

@4.Software control, design wire feeding speed parameters through the control screen, can save multiple sets of data, and call it arbitrarily.

@5.Visable control screen,more easy to set

@6.Double wires feeder

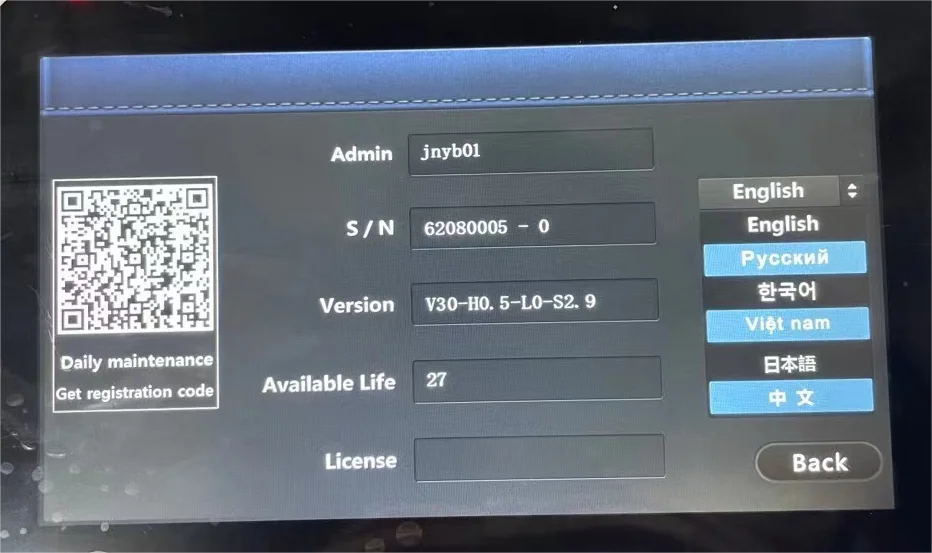

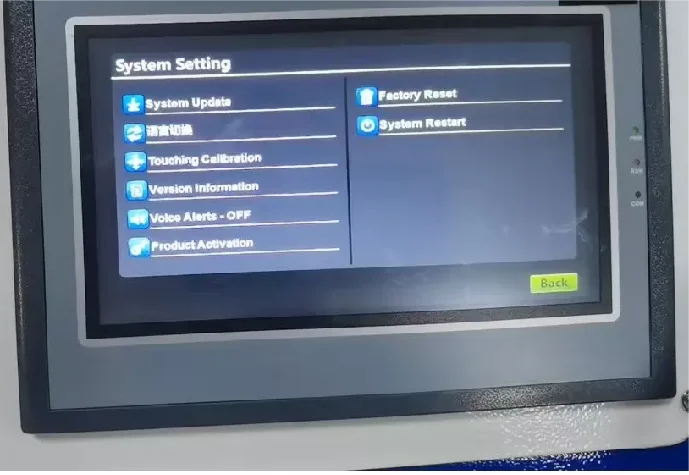

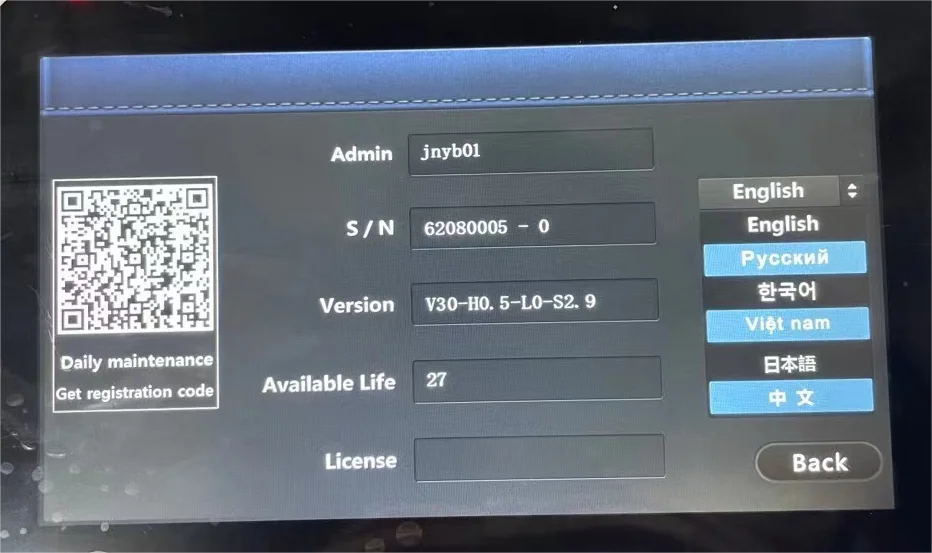

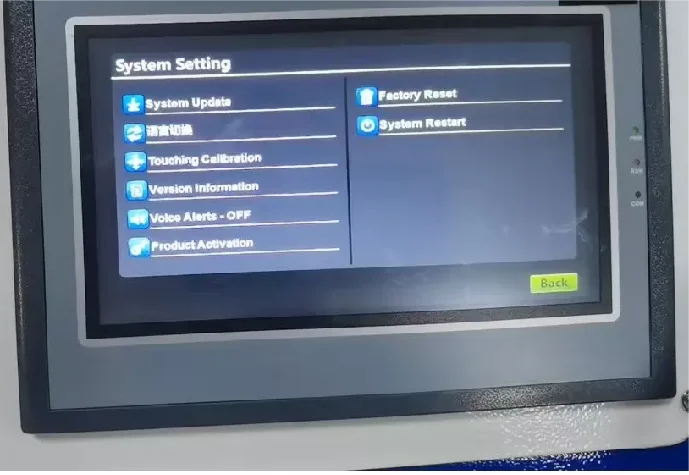

Control System

Easy and Multilanguage System

Laser Head

Weight: 0.7KG ONLY

Weight: 0.7KG ONLY

Cooling system

(1) The three-layer condenser sub-technology has large cooling capacity and good heat dissipation, ensuring the equipment is durable in harsh environments.

(2) The water quality is good, the precision is high, and the laser is carefully taken care of to prolong its service life.

(3) With automatic heating and heating technology, it can reduce the waiting time for customers to turn on the laser in winter and improve production efficiency.

(4) The arc-shaped design, the atmosphere is beautiful, and the laser is improved equipment The matching grade.

(5) Energy-saving and electricity-saving, effectively reducing customers' production costs.

(6) High, medium and low matching to meet the diversified needs of customers.

Flexible optical fiber and full set cutting nozzles

A single laser welding system is equipped with a length of15riceFlexible fiber; The bending radius can reach 80MM. When the optical fiber transmits energy, the laser optical fiber has perfect self-protection function. It can automatically cut off the optical path or turn off the laser in the case of fiber wear and aging, too small bending radius, overheating and laser leakage, to ensure the safety of personnel and the use of fiber.

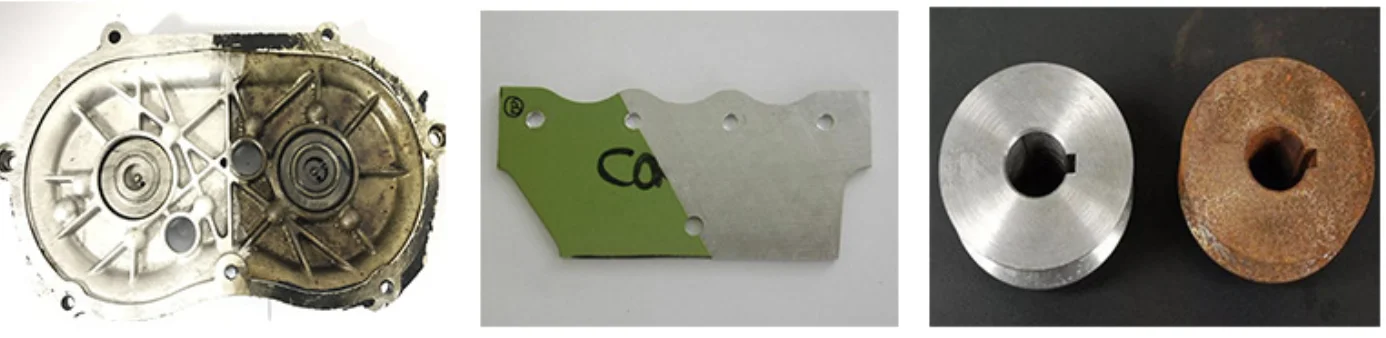

Processed samples-Welding

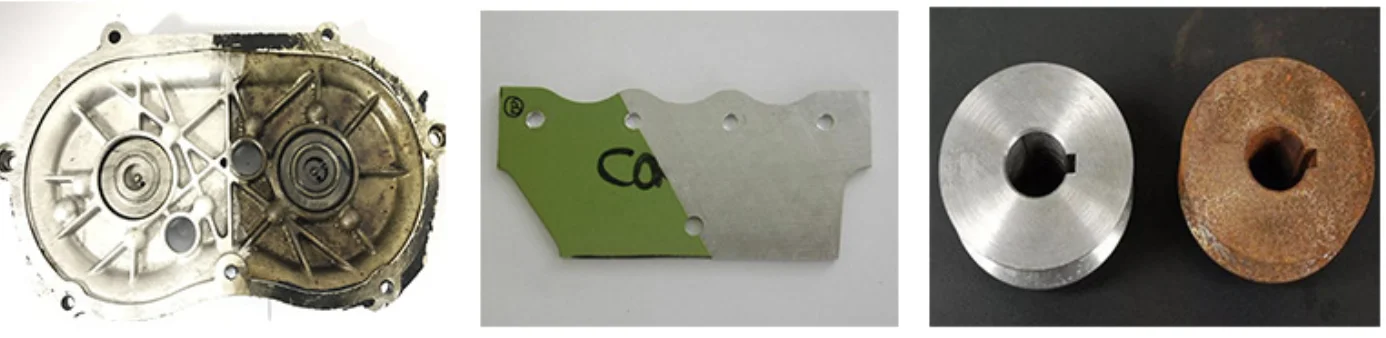

Processed Samples-Cleaning

Processed samples- Cutting

Related Production Line Machines You Might Be Interested In:

Jinan Smart Technology Co.,ltd (SMARTECH)

100 meters south of fengqi,Shizhong District,Jinan,Shandong China

Whats App:+0086-15064149218

Official Website:

https://www.jncnclaser.com

https://smartcnc.en.alibaba.com/

https://www.facebook.com/smartcnclaser/

https://www.instagram.com/smartcnclasermachine/

https://twitter.com/SmartCNCLaser

https://www.youtube.com/channel/UC_KHu77gwdXcP0xStzYIPAg

https://www.pinterest.com/chinasmartech/

To Improve Your Business Is Our Business Goal!--21 Years' Manufacturing experience!

Machine Offer

2023 New Desing Model: Smart -P3000W

Main Configuration:

#Fiber laser power 3000W Max/Raycus;

#New Generation laser head SUP 21T

#Double wires feeder

#Schneider parts for electricity

#Fiber cable 20 meters instead of 10;

#Ultra-light weight and compact, it swings the light spot left and right, and has a safety circuit trigger protection function.

#Multi-language operation interface, touch screen control System

#One-piece design,With universal walking casters

#Wire feeding system;

#Hanli/S&A Water Chiller;

#Intelligent control system Wire feeding mechanism

General Information

Features:

1.4 in 1 multifunctional which is more cost effective,your best choice !

2.The internal design is smart, and the good interactive control system expands the tolerance range of the processed parts and the width of the weld seam(range 0-6mm), solves the disadvantage of small light spot, and makes the weld seam better.

3.Lightweight, using body engineering design method, comfortable grip; easy control with one hand

4.simple operation,Easy to use,no have to be experienced workers,fresh workers are fine.

5.With multiple safety alarms, the light will be automatically locked after the work piece is removed, which is highly safe.

6.Beautiful welding seam, fast speed, no welding marks,not deformation, not blackening, strong welding, no grinding required no need for later polishing,Consumables few.

7.Various angle nozzles can be configured to meet the welding needs of different products. 8.Swing welding head can be used for welding at any angle or shape.

Performance characteristics

1.Adapt for various metal materials, Carbon steel, stainless steel, high-strength steel, aluminum, copper and alloy materials;

2.The light can be emitted continuously or pulsed, not only for thermal conductivity, but also for continuous deep penetration. It can realize spot welding, butt welding, stitch welding, sealing welding, seam welding, cleaning,cutting.

3.Adopt continuous Fiber laser, excellent beam quality, maintenance-free, photoelectric conversion efficiency is greater than 25%, and the service life of the pump source is greater than 100,000 hours;

4.Fast processing speed;

5.Small thermal deformation and heat affected zone (suitable for processing high melting point, high hardness, special materials);

6.It can process parts with complex shapes and small parts, and can also be processed in vacuum;

7.and Robotic arm and other automated institutions Combined, the processing can be automated; 8.Can realize filler wire welding,Due to advanced processimethods, existproduct structures and materials can be improved.

Technical data

Model | Smart-W1500 | Smart-W2000 | Smart-W3000 |

Laser type | Continuous fiber laser | ||

Rated output power | 1500W | 2000W | 3000W |

Power adjustment range | 10%~100% | ||

Applicable wavelength | 1070 nm | ||

output method | Continuous/modulation | ||

Maximum modulation frequency | 50kHz | ||

Power instability | <3% | ||

Max air pressure | 15 Bar | ||

Fiber output interface | QBH | ||

Indicating system | Red light | ||

Fiber length | 15mm | ||

Fiber cable length | 20m | ||

Torch type | 4 in 1 laser head | ||

Collimated focal length | 60mm | ||

Focus focal length | 150mm | ||

Spot adjustment range | 0-8mm | ||

Torch weight | 0.7 kg | |||

Protective gas method | Coaxial protection | |||

Adjustable weld width | 0~6mm | |||

Water flow | >15L/min | >25L/min | >30L/min | |

product structure | Standard/ Mini | |||

Product size L*D*H | 1200*600*1300mm/ 680*590*1140mm | |||

product weight | 160kg/150kg | |||

Working temperature | 10~40℃ | |||

Working environment humidity | <70% | |||

Operating Voltage | Single phase 220VAC | Three-phase five-wire 380VACSingle phase 220VAC | ||

Total power | <7kw | <9.5 kw | <16 kw | |

Accessories

Random accessories come with machine | ||

Item | Quantity | Remark |

wrench | 1 pair | GIFT |

barometer | 1 piece | GIFT |

Gloves | 1 pair | GIFT |

Protective lens | 5 slices | GIFT |

Wire | 1 box | GIFT |

Copper mouth | 8 | GIFT |

Product manual | 1 serving | GIFT |

Certificate of conformity | 1 serving | |

Warranty Card | 1 serving | |

Laser manual | 1 serving | |

Laser U Disk Information | 1set | |

Machine - Introduction

Machine - Side View

Laser Power Source

Max Laser Source

Raycus Laser Source

Wire Feeding System

Features of laser head:

@1.Easy installation, long life, low noise, low energy consumption;

@2.Small size, small weight, large torque, can be used with long-distance hand-held welding wire feeding;

@3.Wire feeding and welding control are synchronized, the wire feeding is stable and adjustable, suitable for use in different scenarios, and it is easy for the operator to master and quickly get started and skillfully operate.

@4.Software control, design wire feeding speed parameters through the control screen, can save multiple sets of data, and call it arbitrarily.

@5.Visable control screen,more easy to set

@6.Double wires feeder

Control System

Easy and Multilanguage System

Laser Head

Weight: 0.7KG ONLY

Weight: 0.7KG ONLY

Cooling system

(1) The three-layer condenser sub-technology has large cooling capacity and good heat dissipation, ensuring the equipment is durable in harsh environments.

(2) The water quality is good, the precision is high, and the laser is carefully taken care of to prolong its service life.

(3) With automatic heating and heating technology, it can reduce the waiting time for customers to turn on the laser in winter and improve production efficiency.

(4) The arc-shaped design, the atmosphere is beautiful, and the laser is improved equipment The matching grade.

(5) Energy-saving and electricity-saving, effectively reducing customers' production costs.

(6) High, medium and low matching to meet the diversified needs of customers.

Flexible optical fiber and full set cutting nozzles

A single laser welding system is equipped with a length of15riceFlexible fiber; The bending radius can reach 80MM. When the optical fiber transmits energy, the laser optical fiber has perfect self-protection function. It can automatically cut off the optical path or turn off the laser in the case of fiber wear and aging, too small bending radius, overheating and laser leakage, to ensure the safety of personnel and the use of fiber.

Processed samples-Welding

Processed Samples-Cleaning

Processed samples- Cutting

Related Production Line Machines You Might Be Interested In:

Jinan Smart Technology Co.,ltd (SMARTECH)

100 meters south of fengqi,Shizhong District,Jinan,Shandong China

Whats App:+0086-15064149218

Official Website:

https://www.jncnclaser.com

https://smartcnc.en.alibaba.com/

https://www.facebook.com/smartcnclaser/

https://www.instagram.com/smartcnclasermachine/

https://twitter.com/SmartCNCLaser

https://www.youtube.com/channel/UC_KHu77gwdXcP0xStzYIPAg

https://www.pinterest.com/chinasmartech/

To Improve Your Business Is Our Business Goal!--21 Years' Manufacturing experience!