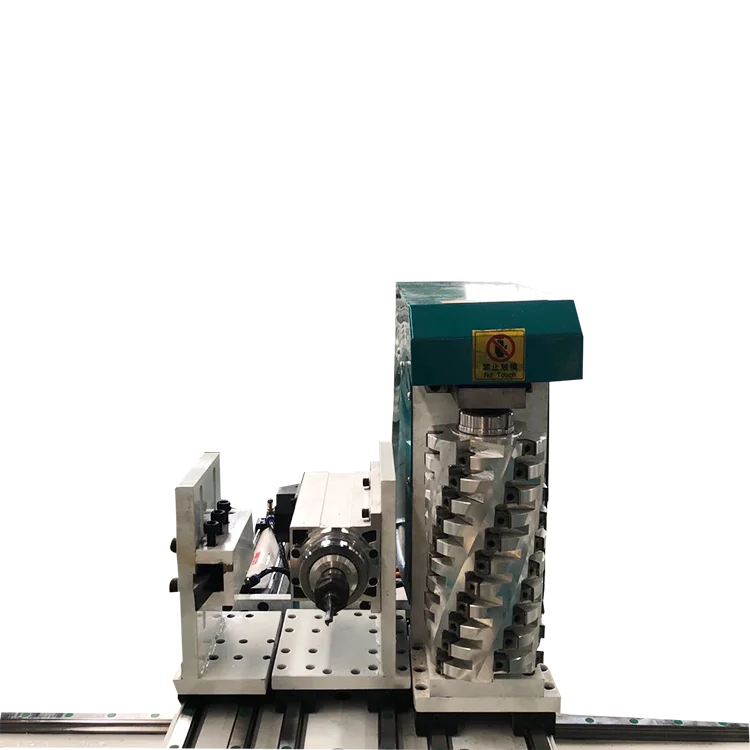

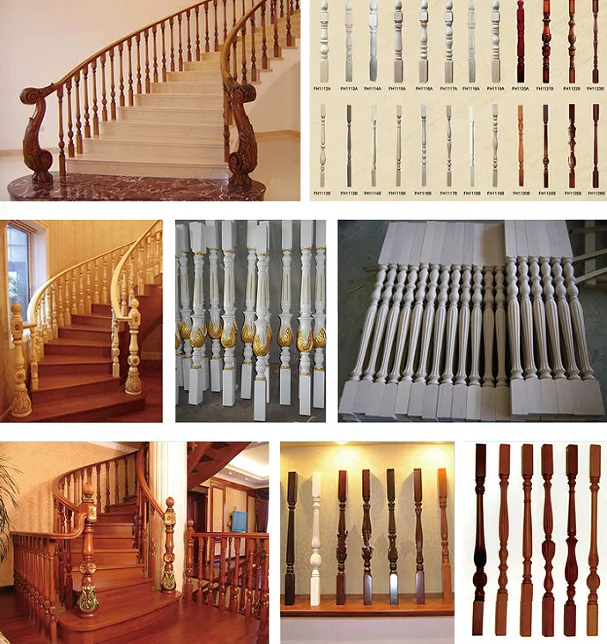

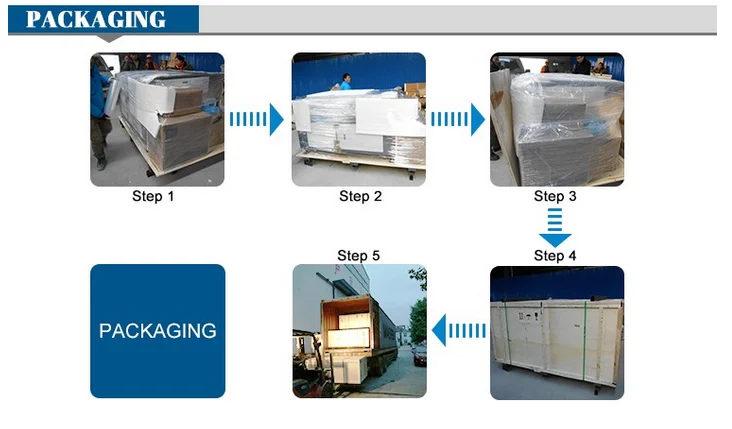

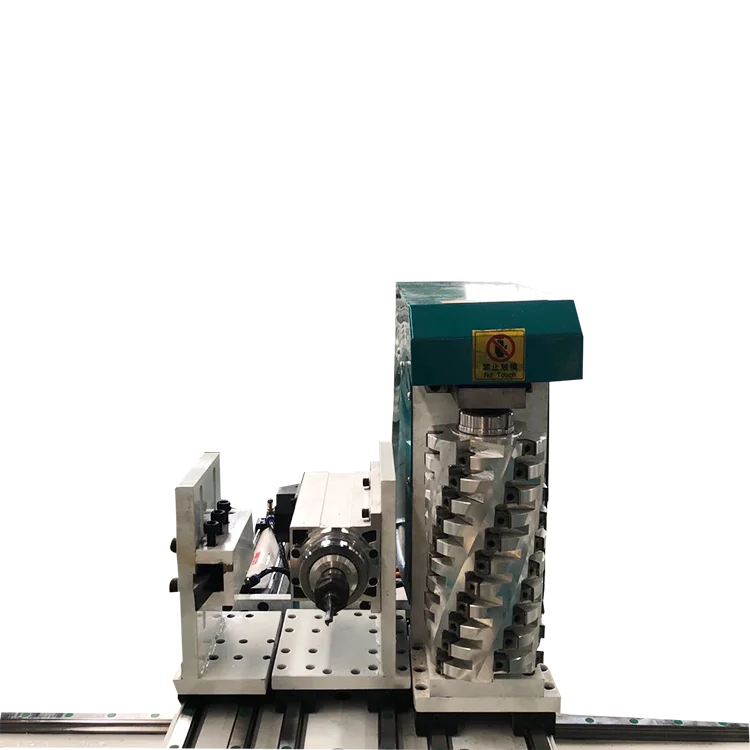

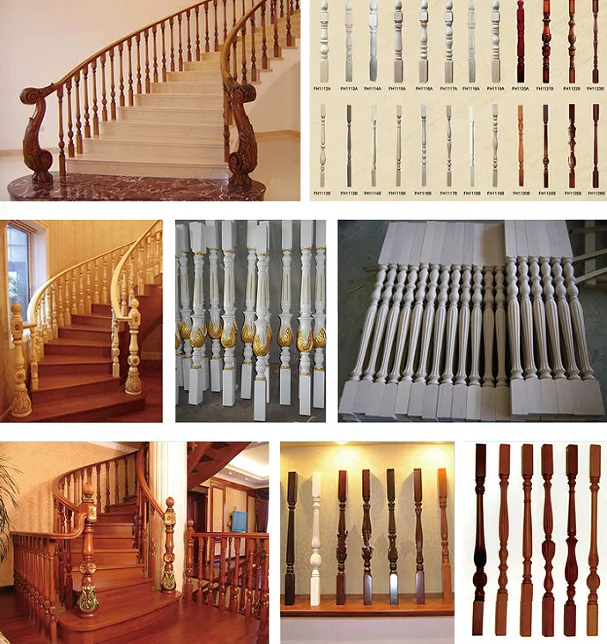

SL1530-P Model For wooden chairs making *Working area:1500mm(L)X300MM(Diameter) *Cast iron body (not easy to be deformed and will not be wobbly after 10 years,better than welded body) *4KW Four grade pure cooper 3 phase asynchronous motor *Motors 3 pieces(XY Axis 450B 10Nm,Z axis 450C 12Nm) *Rails and blocks 25 mm/ 32mm ball screw for y axis *Y axis Helical rack gear transmission *Fuling inverter *Fuwang first grade best quality blades * DSP Controller *Filter/Leakage protector *Helical tooth rails,higher efficiency With optional part @2.Change into 4 axis system: (for designs’ engraving) @3.Add optional auto feeding system @4.Add optional polishing system(for products polishing) @5.Add optional shaving tool @6.Give 2 sets more belts for free for spare parts. 7,999 USD FOB Qingdao port 1 SET Optional parts: @1.Electrical blade system for bowls making +600 USD Warranty:3 years since delivery Payment:30% deposit,70% T.T after machine production is finished from your company bank to our company bank. Or payment assurance Lead time: 15 working days for standards