| Availability: | |

|---|---|

CNC Oscillating Knife Machine For Leather/bags/garment/fabric/pvc/carpet/cloth/kt board

SMARTECH

New Product 2020

3600*2280*1600

1100W

red

Applicable materials

Leather, cardboard, paper honeycomb, corrugated cardboard, glass fiber, carbon fiber, sticker, film, KT-board, foam board, acrylic board, rubber, cloth, fabric, gasket material, garment cloth, footwear materials, bags materials, non-woven fabrics, carpets materials, car mat materials, sponge, PU, EVA, XPE, PVC, PP,PE, PTFE, ETFE and composites.

Advantages

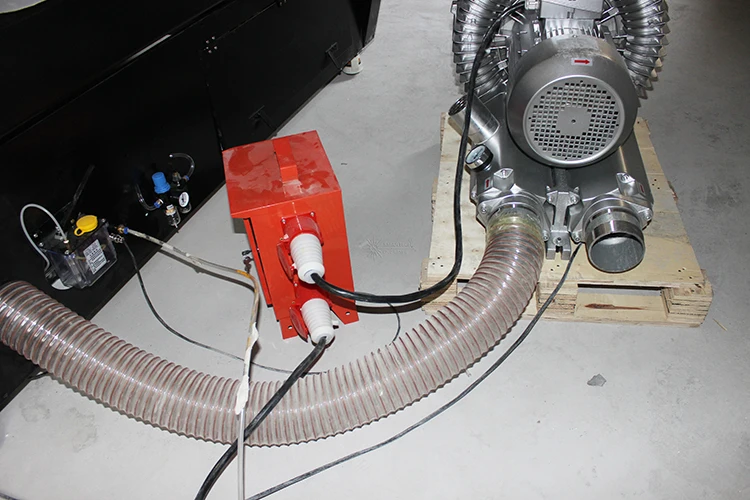

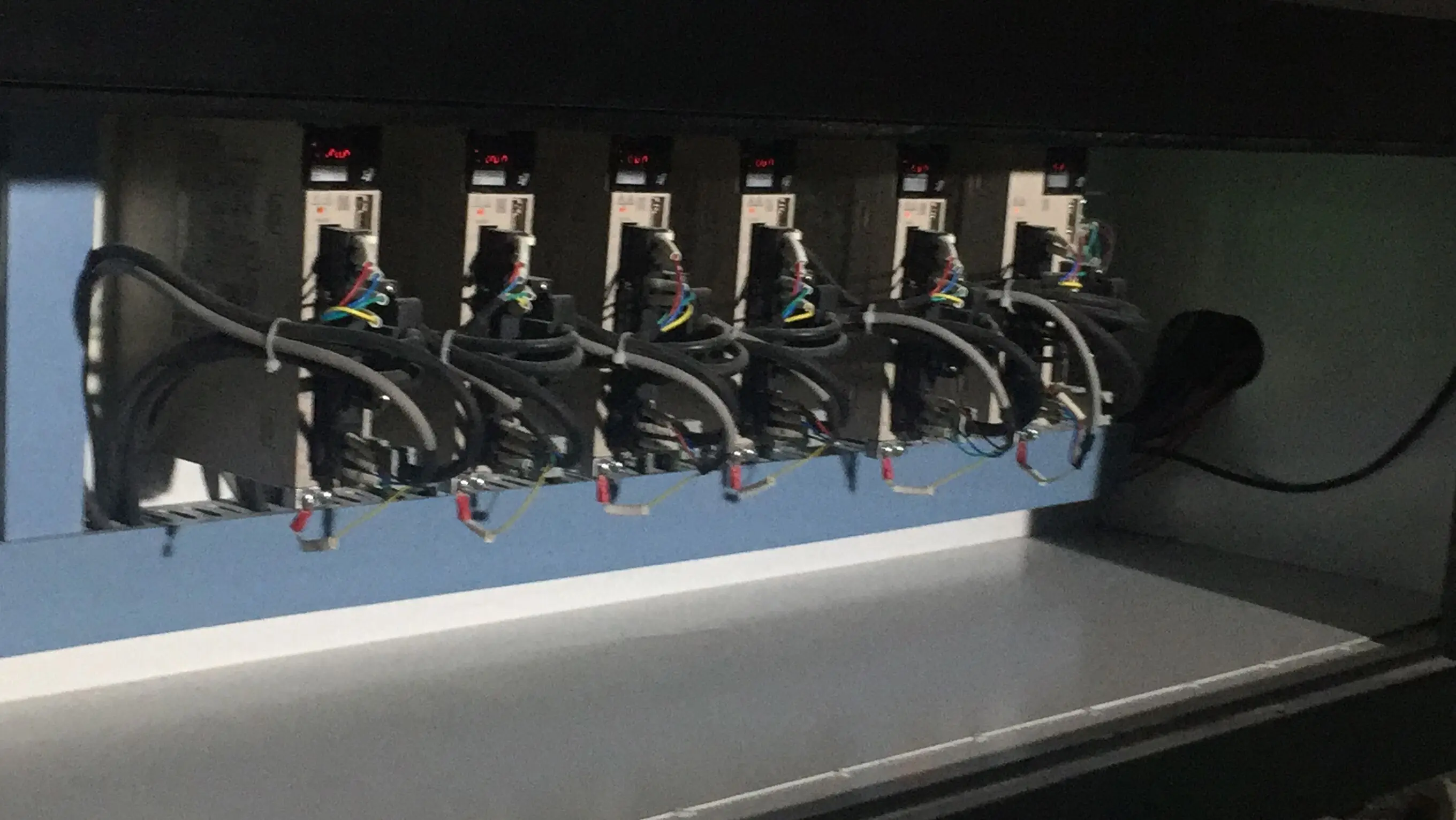

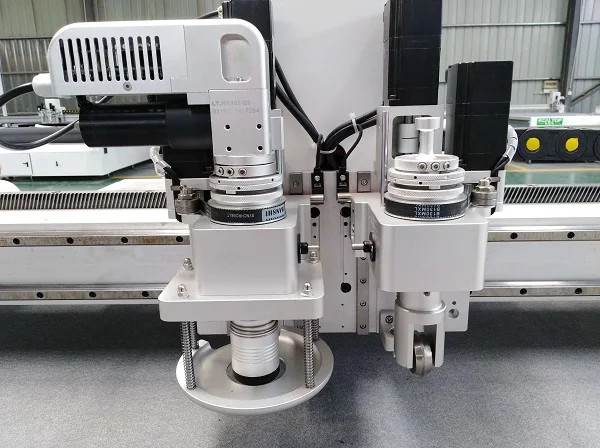

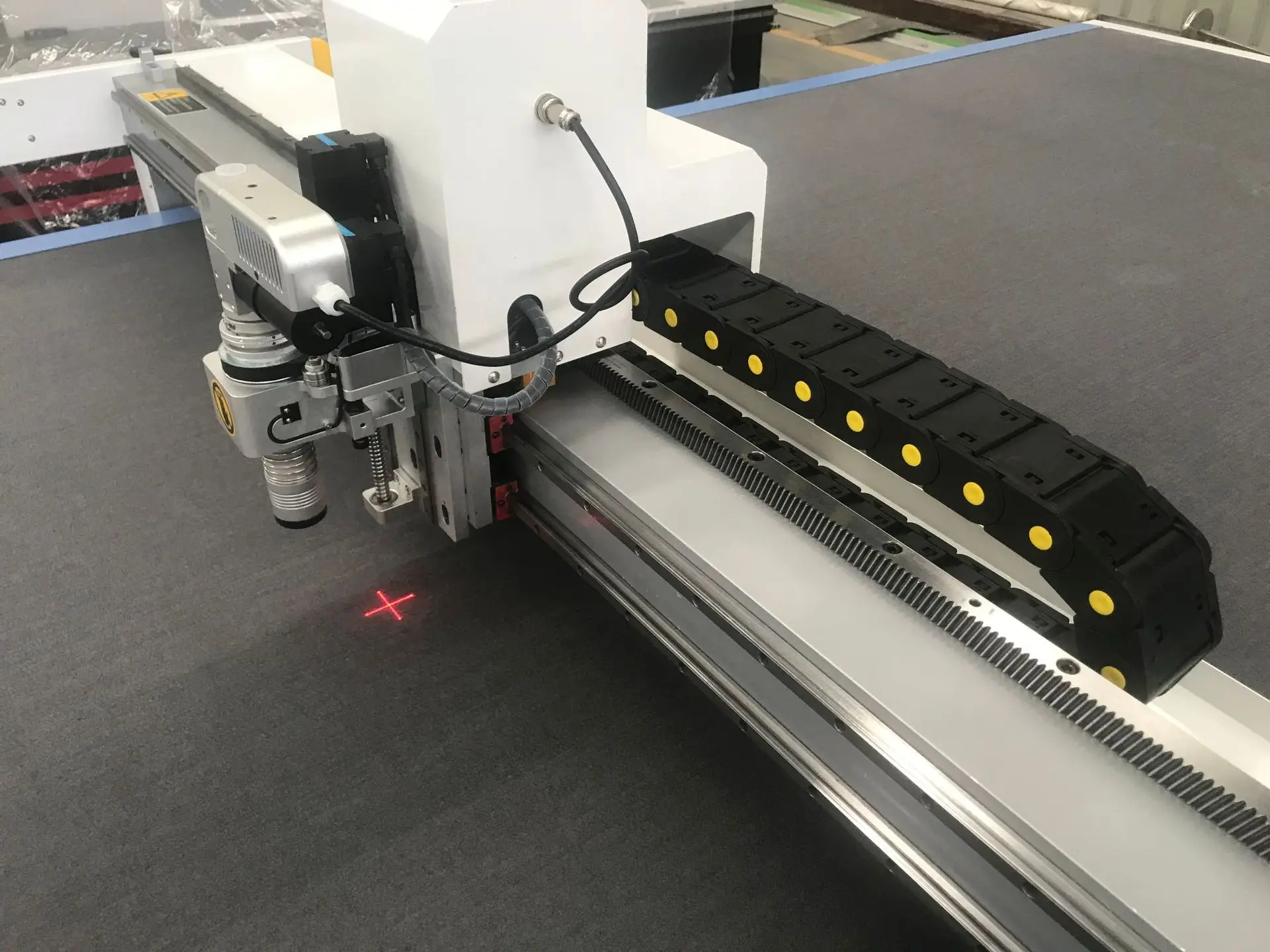

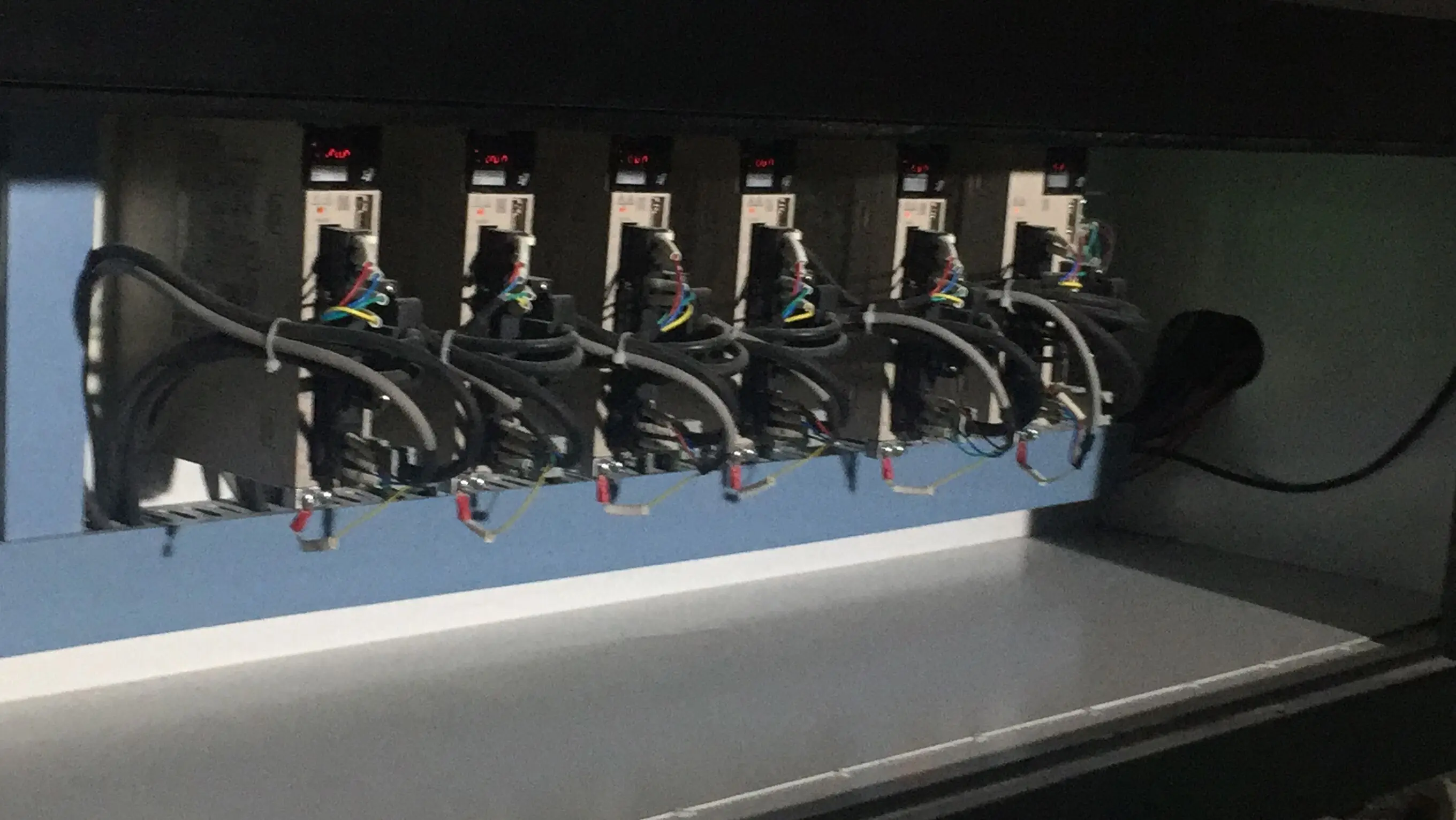

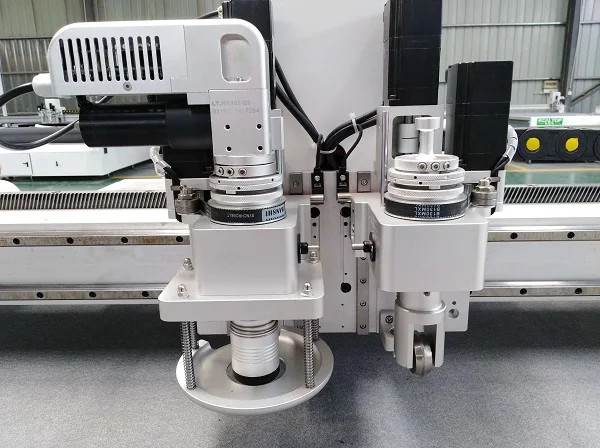

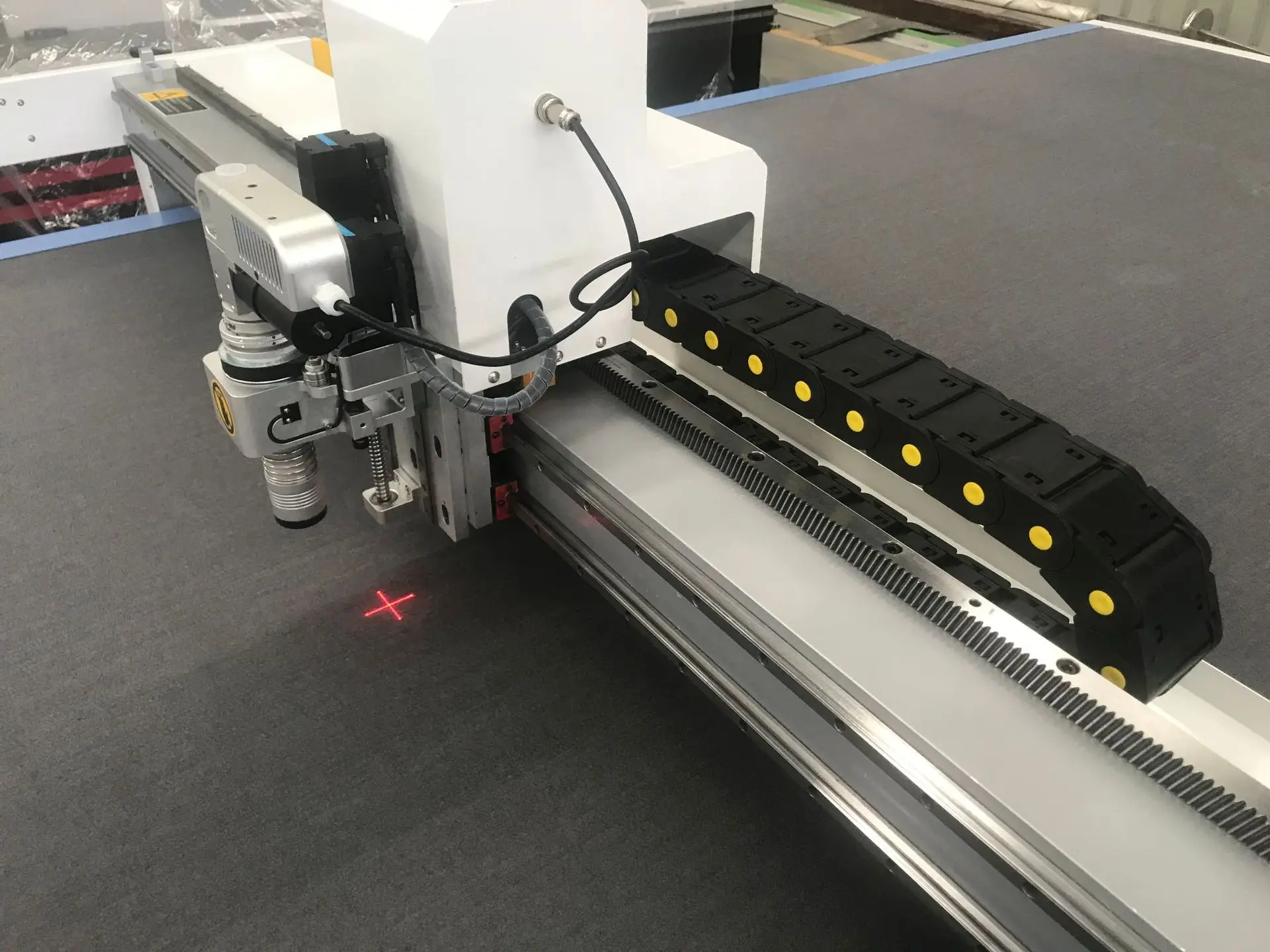

SMARTECH CNC oscillating knife leather cutting machine is designed for production with small quantities and can save Features: Automatic CNC Oscillating Knife Cutting Fabric Leather PVC Cutter Machines for sale 1. Imported Taiwan square linear guide and Japanese servo motor ensure high accuracy, fast cutting speed and stable working performance; 2. Whole machine is welded with thick square seamless steel structure and treated with high temperature, ensures high accuracy, no deformation and super long service life; 3. The whole piece aluminum platform is honeycomb structure, not easy to deform, sound-absorbing, etc. 4. SMARTECH digital cutting machine was designed easy to install, set-up and operate; 5. Being equipped with infrared sensor and emergency stop devices, guarantees safety; 6. Cutting by knife not laser, no air pollution, no burnt edge, cutting speed is 5-8 times faster than laser cutting machine;

Automatic CNC Oscillating Knife Cutting Fabric Leather PVC Cutter Machines for sale 1. Imported Taiwan square linear guide and Japanese servo motor ensure high accuracy, fast cutting speed and stable working performance; 2. Whole machine is welded with thick square seamless steel structure and treated with high temperature, ensures high accuracy, no deformation and super long service life; 3. The whole piece aluminum platform is honeycomb structure, not easy to deform, sound-absorbing, etc. 4. SMARTECH digital cutting machine was designed easy to install, set-up and operate; 5. Being equipped with infrared sensor and emergency stop devices, guarantees safety; 6. Cutting by knife not laser, no air pollution, no burnt edge, cutting speed is 5-8 times faster than laser cutting machine;

Applicable materials

Leather, cardboard, paper honeycomb, corrugated cardboard, glass fiber, carbon fiber, sticker, film, KT-board, foam board, acrylic board, rubber, cloth, fabric, gasket material, garment cloth, footwear materials, bags materials, non-woven fabrics, carpets materials, car mat materials, sponge, PU, EVA, XPE, PVC, PP,PE, PTFE, ETFE and composites.

Advantages

SMARTECH CNC oscillating knife leather cutting machine is designed for production with small quantities and can save Features: Automatic CNC Oscillating Knife Cutting Fabric Leather PVC Cutter Machines for sale 1. Imported Taiwan square linear guide and Japanese servo motor ensure high accuracy, fast cutting speed and stable working performance; 2. Whole machine is welded with thick square seamless steel structure and treated with high temperature, ensures high accuracy, no deformation and super long service life; 3. The whole piece aluminum platform is honeycomb structure, not easy to deform, sound-absorbing, etc. 4. SMARTECH digital cutting machine was designed easy to install, set-up and operate; 5. Being equipped with infrared sensor and emergency stop devices, guarantees safety; 6. Cutting by knife not laser, no air pollution, no burnt edge, cutting speed is 5-8 times faster than laser cutting machine;

Automatic CNC Oscillating Knife Cutting Fabric Leather PVC Cutter Machines for sale 1. Imported Taiwan square linear guide and Japanese servo motor ensure high accuracy, fast cutting speed and stable working performance; 2. Whole machine is welded with thick square seamless steel structure and treated with high temperature, ensures high accuracy, no deformation and super long service life; 3. The whole piece aluminum platform is honeycomb structure, not easy to deform, sound-absorbing, etc. 4. SMARTECH digital cutting machine was designed easy to install, set-up and operate; 5. Being equipped with infrared sensor and emergency stop devices, guarantees safety; 6. Cutting by knife not laser, no air pollution, no burnt edge, cutting speed is 5-8 times faster than laser cutting machine;