Views: 21 Author: Site Editor Publish Time: 2024-03-18 Origin: Site

Fiber vs CO2 vs UV Laser Marking Machines: Picking the Right Fit for Your Business

The differences between fiber laser marking machines, UV laser marking machines and carbon dioxide laser marking machines are reflected in the following three aspects:

1. Laser Source

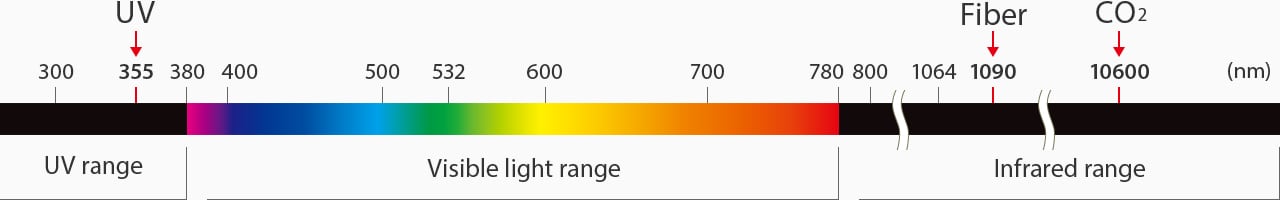

Fiber laser marking machines use fiber lasers, carbon dioxide laser marking machines use CO2 gas lasers, and ultraviolet laser marking machines use short-wavelength ultraviolet lasers. Ultraviolet laser is a technology that is completely different from carbon dioxide and fiber laser technology. Ultraviolet laser is also called a blue laser beam. This technology has low-heat engraving capabilities and is a cold light engraving.

2. Working principle

-Fiber laser marking machine uses laser beam to mark permanent marks on the surface of various materials. The effect of marking is to expose the deep material through the evaporation of the surface material, or to engrave traces through the physical changes of the surface material caused by light energy, or to burn off part of the material through light energy to reveal the required etched patterns and characters. , barcodes and other graphics

-Carbon dioxide laser marking machine fills CO2 gas into a high-voltage discharge tube to generate glow discharge, causing the gas molecules to release laser light. After amplifying the laser energy, a laser beam is formed for material processing. The laser beam causes the surface of the object to be processed to be processed. Gasification achieves the purpose of engraving.

-The principle of UV laser marking machine is similar to that of laser marking machine. They both use laser beam to mark permanent marks on the surface of various materials. The marking effect is to directly break the molecular chains of substances through short-wavelength lasers (unlike the evaporation of surface substances produced by long-wavelength lasers to expose deep substances), thereby revealing the required etched patterns and text.

3.Application fields:

-Fiber laser marking machine can process a variety of metal and non-metal materials, especially for marking high hardness, high melting point, and brittle materials. For example: marking of stainless steel, iron, copper, magnesium, aluminum, gold, silver, titanium, platinum and other metals and various metal oxides. In addition, it can also mark various high-hard alloys, oxides, electroplating, Coating, ABS, epoxy resin, ink, engineering plastics, etc.

-CO2 laser marking machine is mainly used for non-metallic materials, such as leather, cloth, wood, bamboo products, plastics, rubber, PVC, etc. It is widely used in pharmaceutical packaging, food packaging, beverage packaging, plastic, textile, leather , wood, handicrafts, electronic components, communications, watches, glasses, printing and other industries.

-UV laser marking machine is mainly used for ultra-fine marking and engraving. It is especially suitable for applications such as marking food and medical packaging materials, drilling micro holes, high-speed dividing of glass materials, and complex pattern cutting of silicon wafers. field

CO2, Fiber, and UV machines are all incredible tools for cutting and engraving materials. Each of them have their own strengths and weaknesses that make them appeal to various different customers. CO2 machines are quite affordable, while Fiber and UV machines are considered worthwhile investments for growing industries.