| Availability: | |

|---|---|

SMARTECH

New Product 2020

9000mm * 1400mm * 1800mm

5kW

red

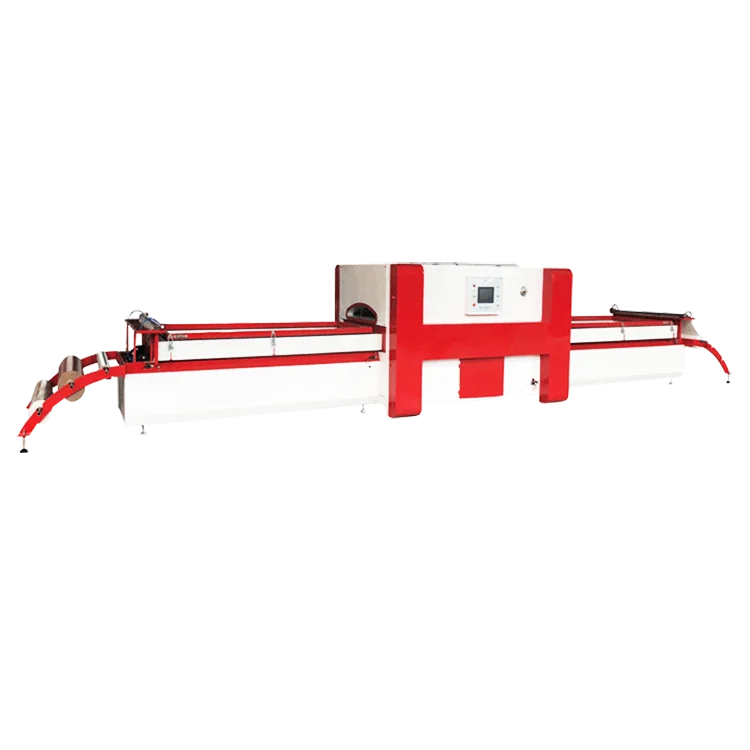

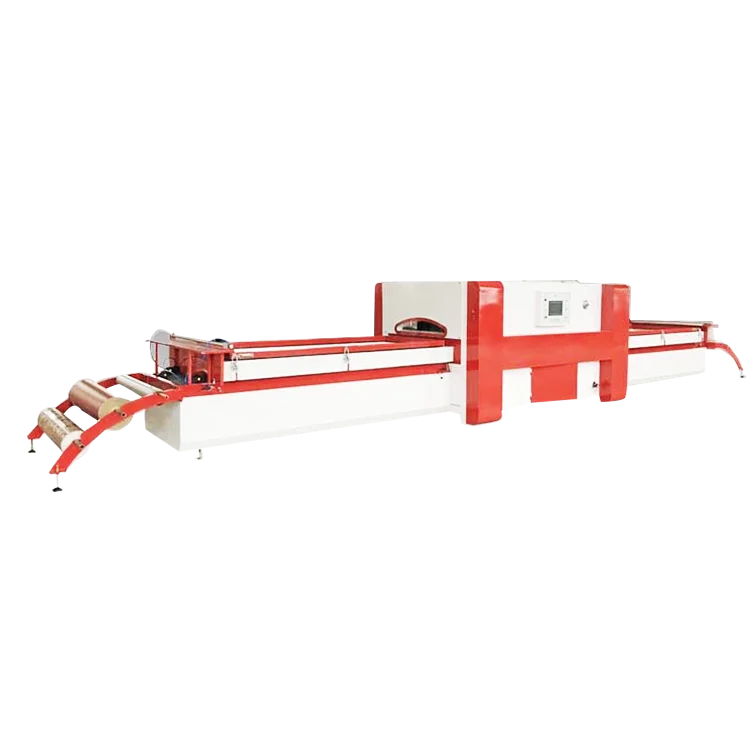

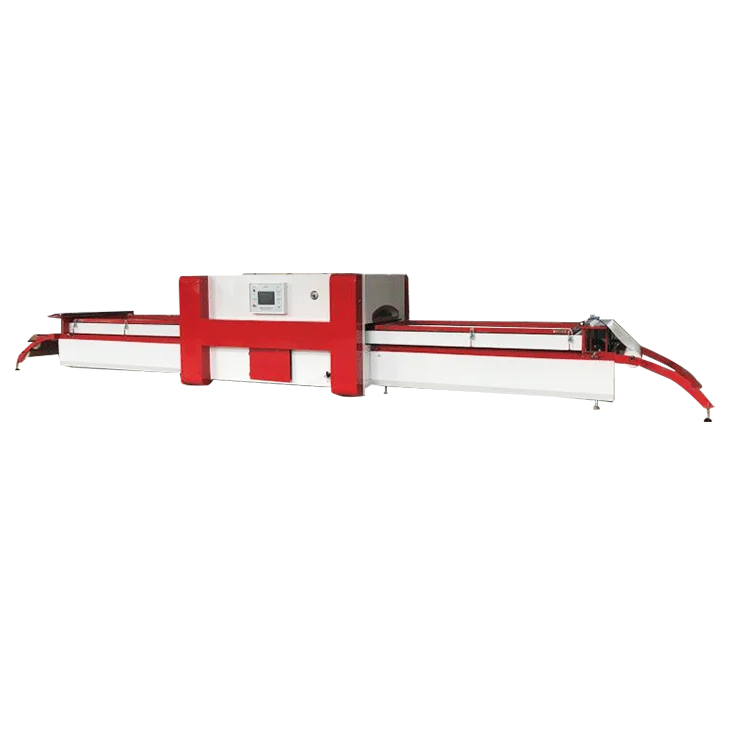

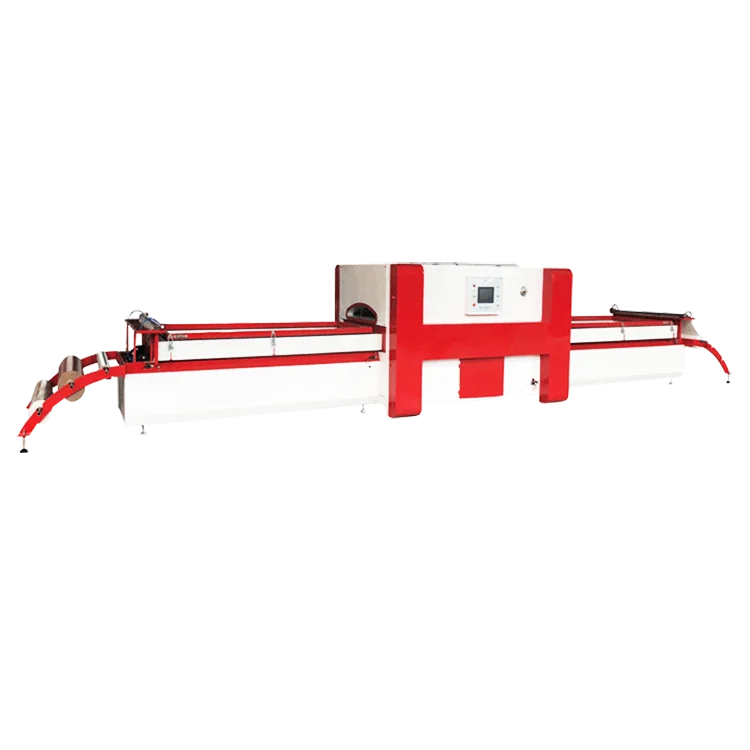

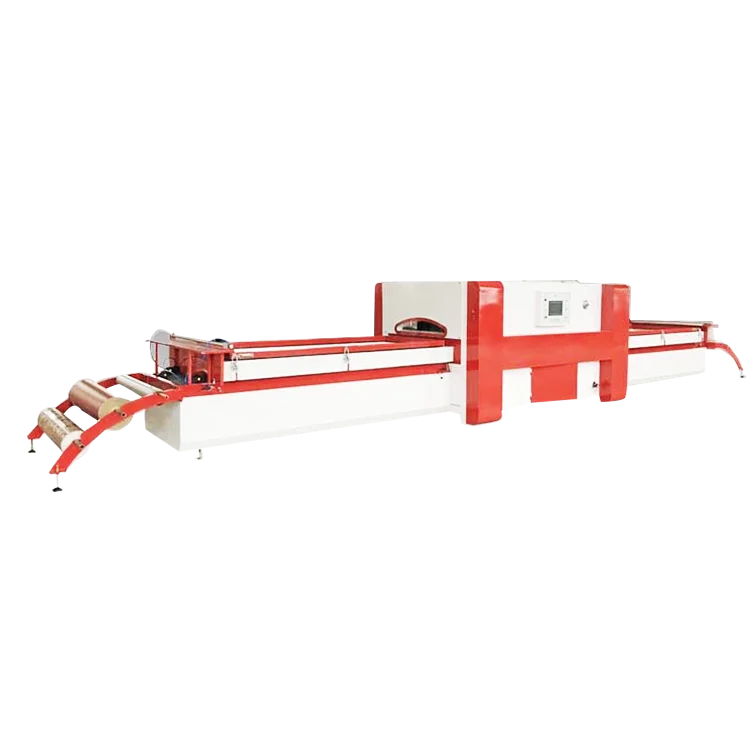

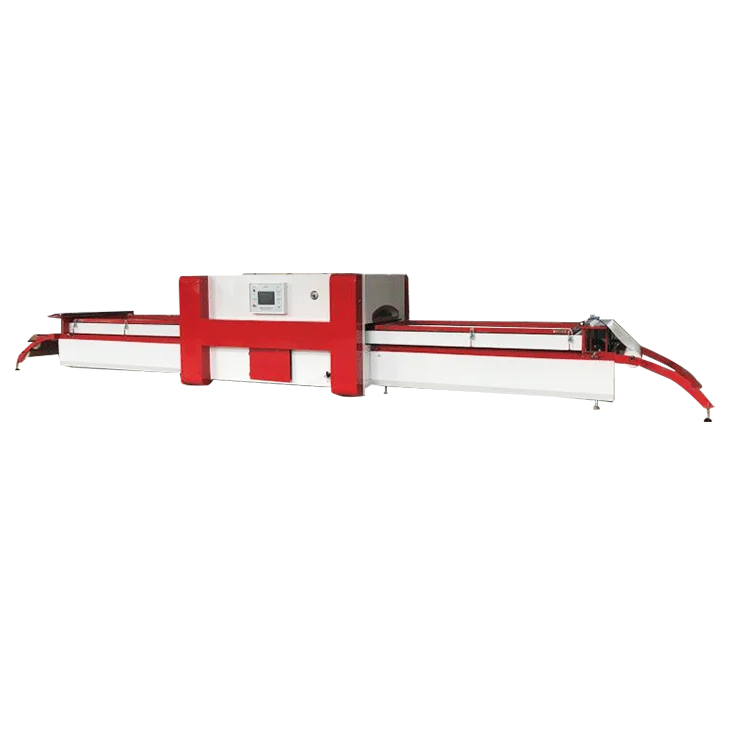

1. This SMARTECH Laminating pvc vacuum membrane machine has 2 work table,The electronic part is fully automatic and digitalized control. The components are produced by famous domestic enterprises with good quality. The temperature is controlled by computer chips so that the heatingspeed is adjustable and the temperature can be perfectly managed.

2. Use infrared heating system and high quality heat preservation material, which can ensure even heating and energy saving.

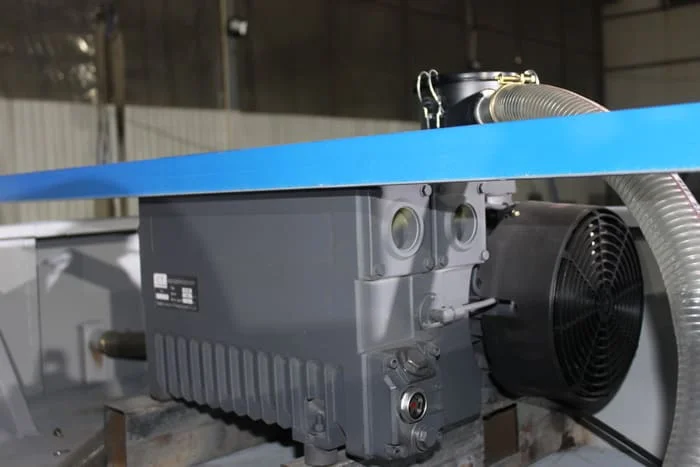

3. This machine uses integrated movement electromotor. It produces less noise and seldom breaks down.

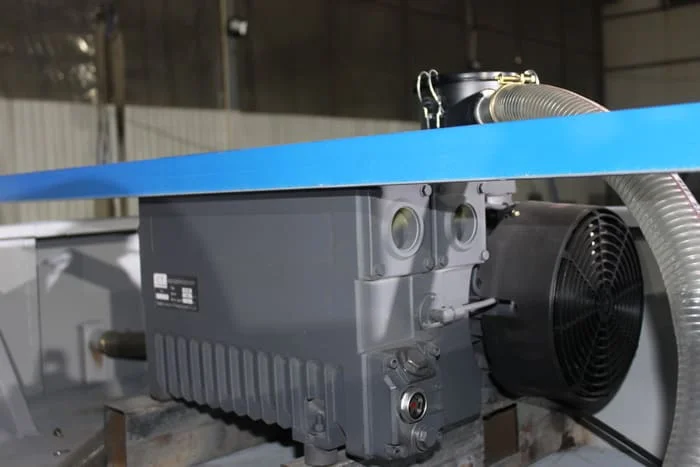

4. This machine uses top 2X series vacuum pump. It is stable and reliable and the maintenance work is simple. (You can also adopt for German-made vacuum pump, which is strong and tough).

5. Large volume vacuum tank. It charges with double channels so that it can work with strong power.

6.Double heating (Up/Down temperature heating) could heat more quickly and save time.

7.Double pumps more powerful.

8.Touching screen instead of the switches, more easy for operation and no potential cost for maintenance.

9.Double observing windows help operators notice the pvc situation more conveniently.

10.Double Edge heating lights to help heat the pvc edges to assure a complete beautiful efficiency.

9,000x1,400x1,800 mm

2) Worktable dimensions: 2,550 x 1,250 (1,300) x 50mm(3000x1250/3500*1250mm for options)

3) Max. processing height: 80mm

4) PVC thickness:0.1-0.45mm;

5)Max vacuum press:-0.1Mpa;

6) Total power: 20kW

7) Actual power:5kW

8)Total weight: 1,500kg

Overall Dimension 9000mm*1400mm*1800mm(Double Table)

Platen Size 2,550 x 1,250 (1,300) x 50mm(3000x1250/3500*1250mm for options)

Max vacuum press: -0.1MpaNumber of worktable One or two

Working speed 2-4min/piece

PVC thickness 0.10-0.60mm

Machine wight 1500kg

The total power 20kw Power Consumable 5kw

Top temperature 180°C

Voltage 380V, 50Hz,3phase

Heating Double upper and lower heating

Vacuum pump XKS vacuum pump

Control system PLC LED Touching Screen

Temperature control Themo couple

Heating system heat preservation

Packing Size 3500×2100×2400mm

PLC Control panel touching score

en

double heating system

Project in Thailand

-Q What is the payment terms? A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A:Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways?

A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China, about 2hours train from Beijing and Shanghai.

-Q Can I arrange sample for cutting test?

A:Yes, always welcome.

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95% customers can learn by themselves.

1. This SMARTECH Laminating pvc vacuum membrane machine has 2 work table,The electronic part is fully automatic and digitalized control. The components are produced by famous domestic enterprises with good quality. The temperature is controlled by computer chips so that the heatingspeed is adjustable and the temperature can be perfectly managed.

2. Use infrared heating system and high quality heat preservation material, which can ensure even heating and energy saving.

3. This machine uses integrated movement electromotor. It produces less noise and seldom breaks down.

4. This machine uses top 2X series vacuum pump. It is stable and reliable and the maintenance work is simple. (You can also adopt for German-made vacuum pump, which is strong and tough).

5. Large volume vacuum tank. It charges with double channels so that it can work with strong power.

6.Double heating (Up/Down temperature heating) could heat more quickly and save time.

7.Double pumps more powerful.

8.Touching screen instead of the switches, more easy for operation and no potential cost for maintenance.

9.Double observing windows help operators notice the pvc situation more conveniently.

10.Double Edge heating lights to help heat the pvc edges to assure a complete beautiful efficiency.

9,000x1,400x1,800 mm

2) Worktable dimensions: 2,550 x 1,250 (1,300) x 50mm(3000x1250/3500*1250mm for options)

3) Max. processing height: 80mm

4) PVC thickness:0.1-0.45mm;

5)Max vacuum press:-0.1Mpa;

6) Total power: 20kW

7) Actual power:5kW

8)Total weight: 1,500kg

Overall Dimension 9000mm*1400mm*1800mm(Double Table)

Platen Size 2,550 x 1,250 (1,300) x 50mm(3000x1250/3500*1250mm for options)

Max vacuum press: -0.1MpaNumber of worktable One or two

Working speed 2-4min/piece

PVC thickness 0.10-0.60mm

Machine wight 1500kg

The total power 20kw Power Consumable 5kw

Top temperature 180°C

Voltage 380V, 50Hz,3phase

Heating Double upper and lower heating

Vacuum pump XKS vacuum pump

Control system PLC LED Touching Screen

Temperature control Themo couple

Heating system heat preservation

Packing Size 3500×2100×2400mm

PLC Control panel touching score

en

double heating system

Project in Thailand

-Q What is the payment terms? A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A:Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways?

A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China, about 2hours train from Beijing and Shanghai.

-Q Can I arrange sample for cutting test?

A:Yes, always welcome.

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95% customers can learn by themselves.