| price: | |

|---|---|

| Availability: | |

SJF

SMARTECH

410CMX300CMX130

1000W/2000W/3000W/6000W

as your preference

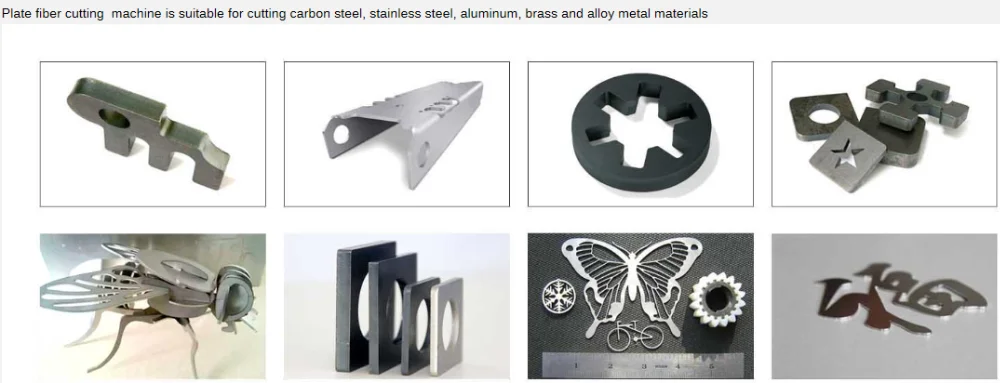

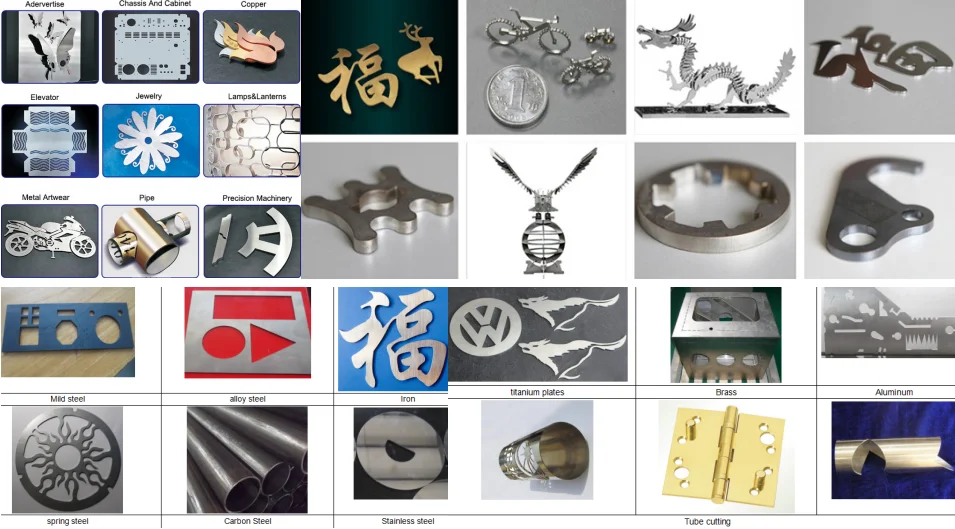

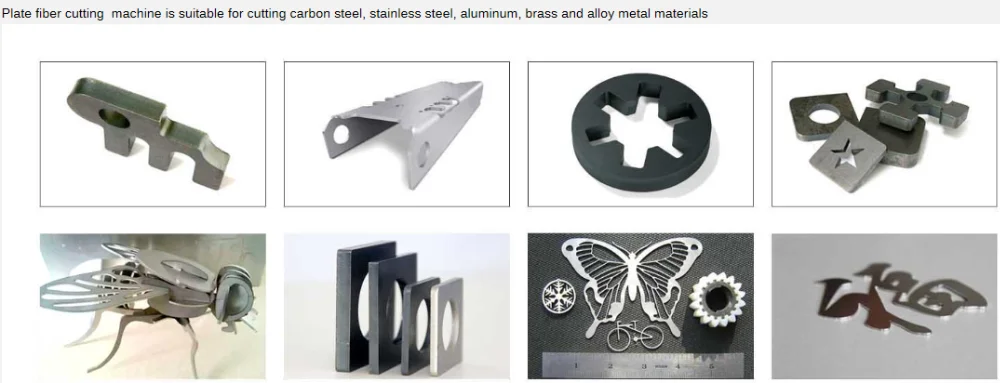

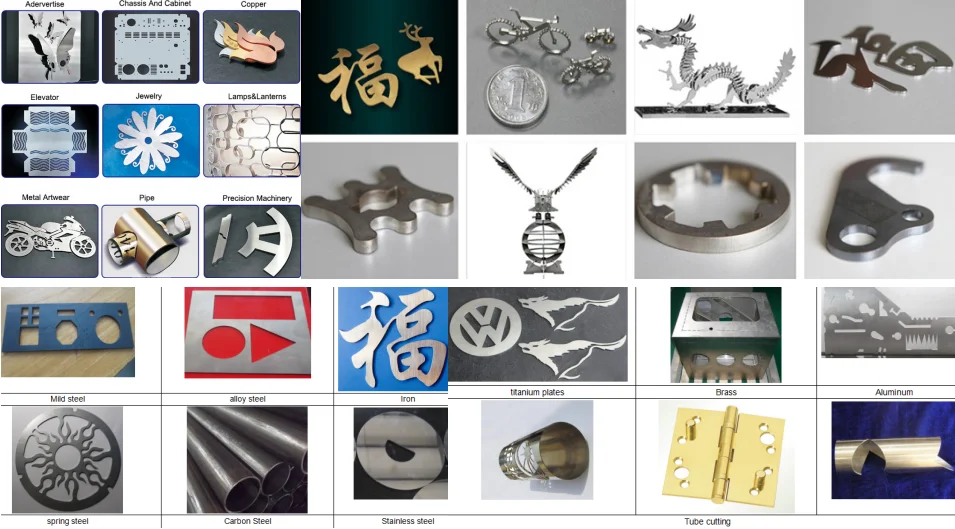

Application Materials:

Fiber Laser Cutting Equipment is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet,

Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet,Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Application Industries:

SMARTECH Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs,Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts,Glasses Frame, Electronic Parts, Nameplates, etc.

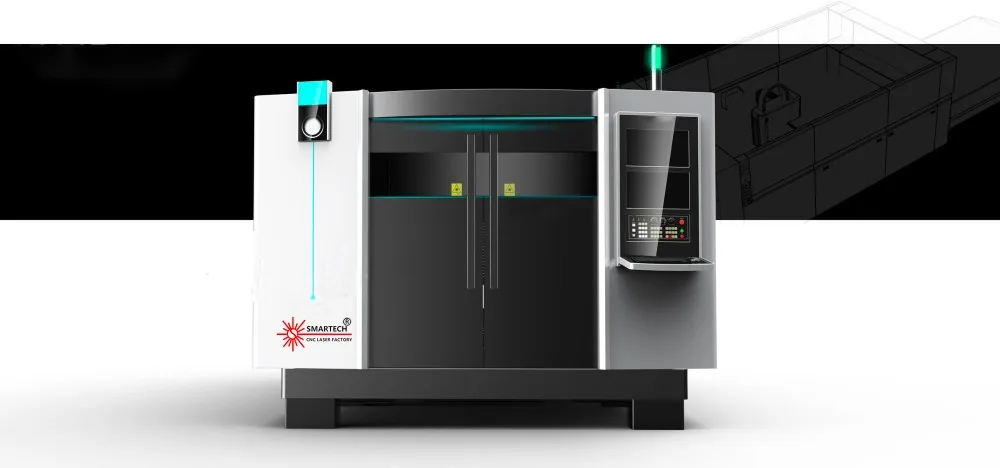

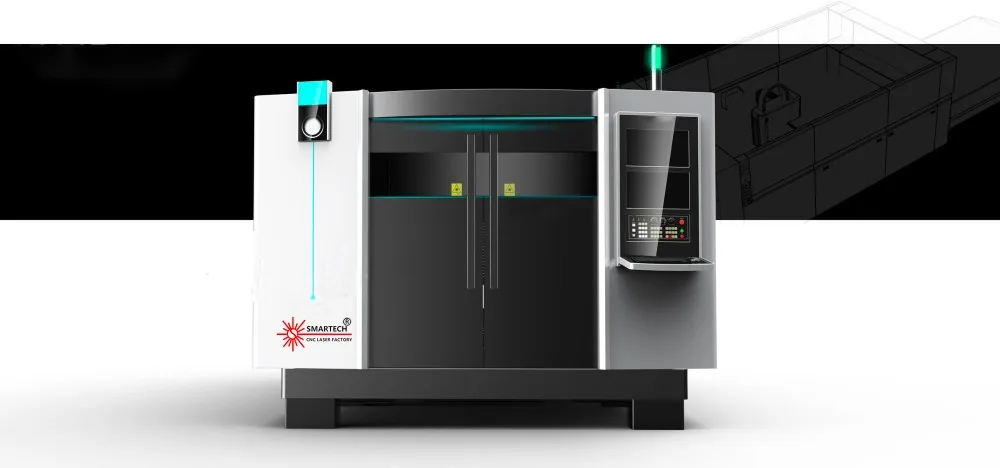

4020 Metal Plate Laser Cutting Machine with full cover and shuttle table Main feature:

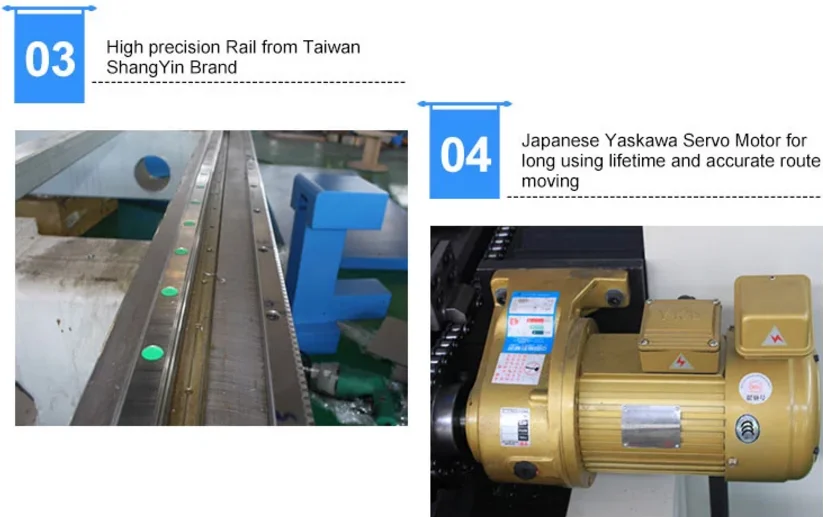

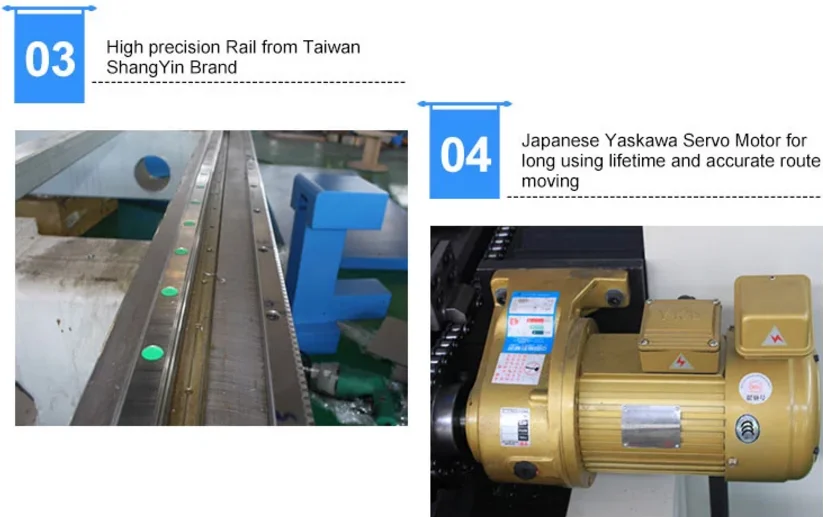

1.High-performance servo transmission equipment, imported gear rack and linear guide, also adopted the Harley laser independent research and development of aluminum alloy extrusion bar, gantry lathe bed ,to ensure that the equipment of high speed, extremely precision.

2.Maximum simultaneous positioning speed: 160m/min

3.Quick and easy installation

4.Up to 300% faster cutting High wall plug efficiency (>30%)

5. Consumable part cost is low. The only parts that need to be changed are nozzles, ceramics and protection glasses over long

periods. There are no other consumable costs.

6.Resonator life is over 100,000 working hours.

7. Double ball screw close-loop system and imported open-type CNC system, ensure high accuracy and high working efficiency during

high speed cutting.

8. Enclosure design conforms to CE standard for reliable and safe processing. Pallet changer is convenient for material uploading and unloading, improving efficiency.

9.Open structure is easy and convenient for material uploading and unloading.

10.Drawer collecting device makes receiving materials more convenient.

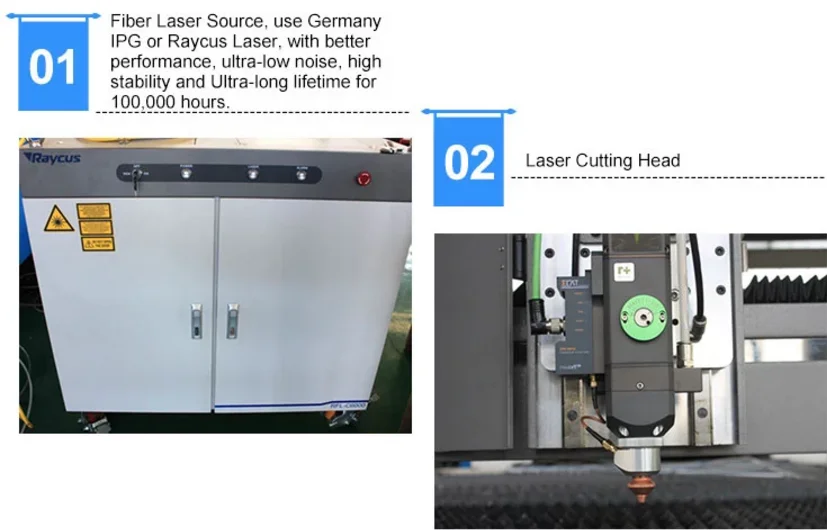

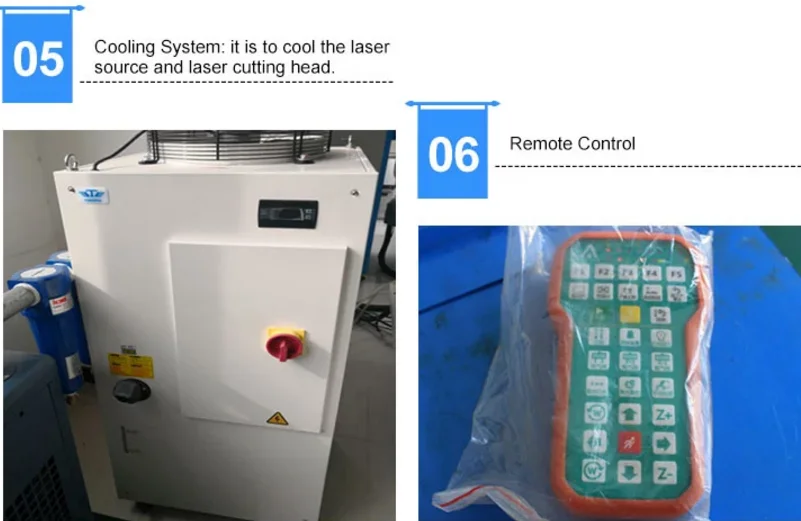

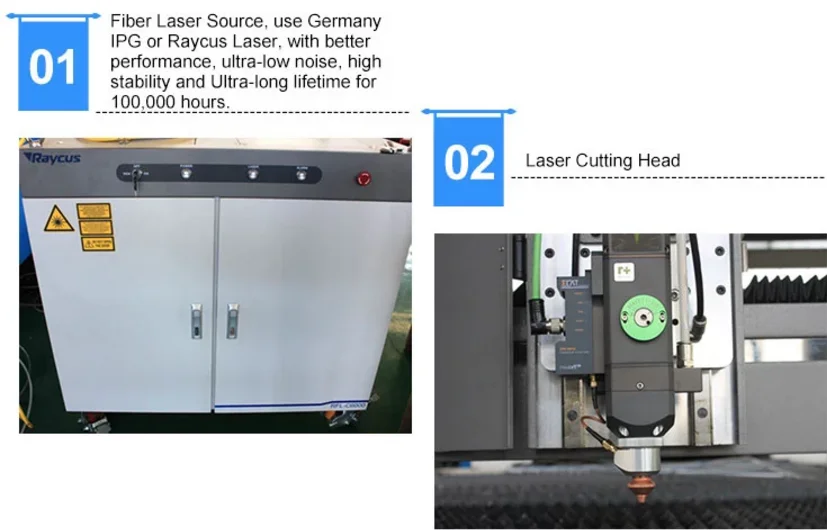

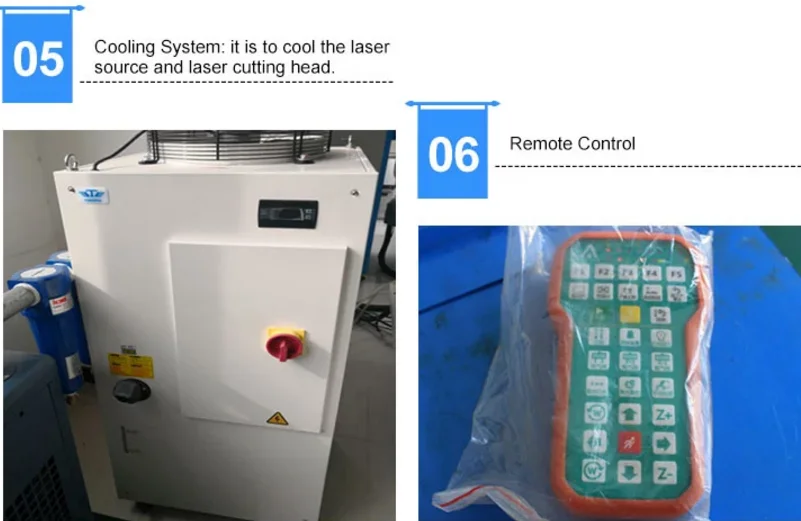

Details Images

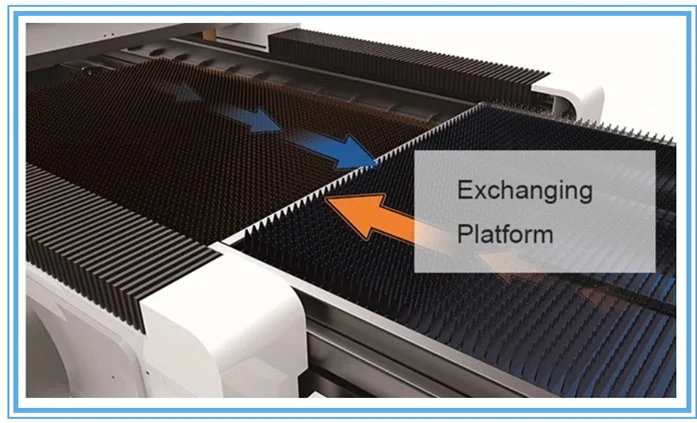

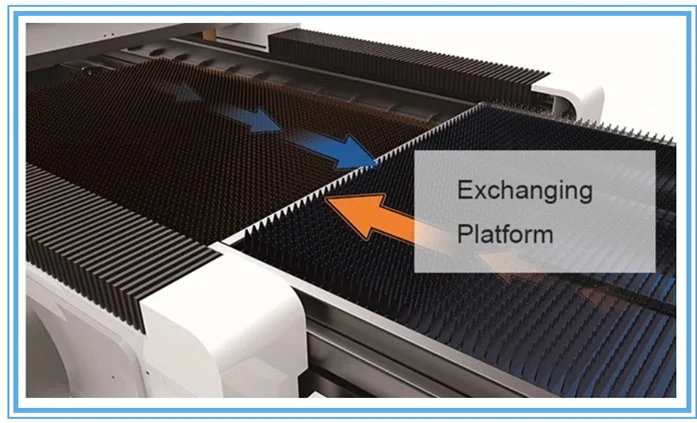

1. Rapid exchanging between two platforms greatly improve work efficiency. Rack and pinion transmission system has higher accuracy, saving feeding time, making operation more efficient.

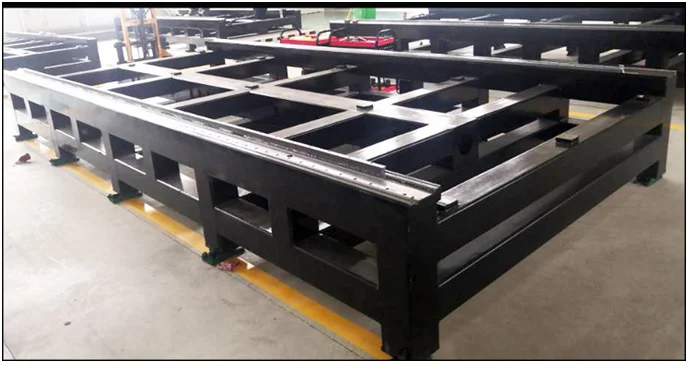

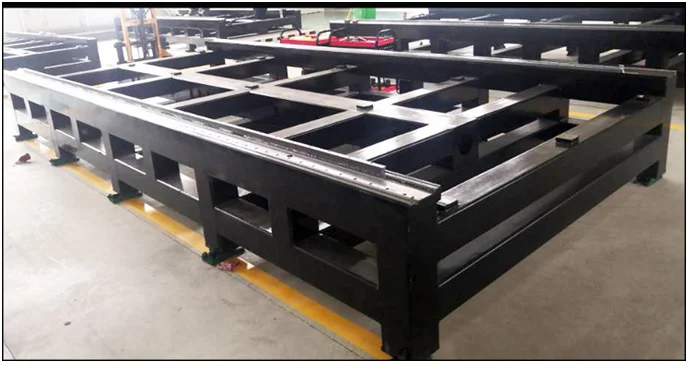

2.Adopt pipe-plate and multiple pipe welding structure or Triangle structure. Strong shock absorption and wear resistance.

3.Good casting and cutting performance. Excellent lubricity, corrosion resistance and dimensional stability.

4.Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using, so the machine accuracy could maintain for a long time, and no deformation in a life cycle.

1.With the professional automatci type seting software ,the cutting plate availability increase 1%-5%,cutting productivity

10%-30%,significantly improve the cut quality ,process data management,data collection and statistics and other data management functions, visualization integrated interface, simple operation ,easy to learn CNC controller is the most widely used and the most sophisticated controller.

2. It is high speed response , mainly used in high-level laser cutting machine. its processing technology and the powerful graphics editing features are very reliable and

practical, extremely High precision.

1.Tempering process

2.The structure adopts industrial heavy steel structure, under heat treatment, suffers lower emperature tempering and annealing, won’t deform after long time use.

3.Flake graphite cast iron with a minimum tensile strength of 200 MPa.

The cast aluminum beam ,Smartech laser cutting machine with light weight, good dynamic response, faster acceleration, better comprehensive cutting effect

Equipment work and environmental requirements

Requirement | |

1 | Cutting with auxiliary gas: Clean, dry compressed air and high purity oxygen (O2) and nitrogen (N2) ,purity no less than 99.9% purity |

2 | The compressed air supply device (1) the rated pressure: 14 bar (2)Capacityt: 1 m3 |

We would provide English Version working manual.

Service

Lifetime after sale service.

Machine warranty: 5 years.(For any questions during warranty period,we would send new parts to you for free!)

On-site training is both available at buyers’ place or seller’s factory

If you have any questions during using and maintaining,our engineers who could speak very good english would answer you online or by calls.

If your machine has big problems if by any chance,our engineers would arrive your place to debug and fix.

Could be remote control at anytime if needed.

Lifetime 24 hours after sale service.

machine recommendation

Application Materials:

Fiber Laser Cutting Equipment is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet,

Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet,Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Application Industries:

SMARTECH Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs,Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts,Glasses Frame, Electronic Parts, Nameplates, etc.

4020 Metal Plate Laser Cutting Machine with full cover and shuttle table Main feature:

1.High-performance servo transmission equipment, imported gear rack and linear guide, also adopted the Harley laser independent research and development of aluminum alloy extrusion bar, gantry lathe bed ,to ensure that the equipment of high speed, extremely precision.

2.Maximum simultaneous positioning speed: 160m/min

3.Quick and easy installation

4.Up to 300% faster cutting High wall plug efficiency (>30%)

5. Consumable part cost is low. The only parts that need to be changed are nozzles, ceramics and protection glasses over long

periods. There are no other consumable costs.

6.Resonator life is over 100,000 working hours.

7. Double ball screw close-loop system and imported open-type CNC system, ensure high accuracy and high working efficiency during

high speed cutting.

8. Enclosure design conforms to CE standard for reliable and safe processing. Pallet changer is convenient for material uploading and unloading, improving efficiency.

9.Open structure is easy and convenient for material uploading and unloading.

10.Drawer collecting device makes receiving materials more convenient.

Details Images

1. Rapid exchanging between two platforms greatly improve work efficiency. Rack and pinion transmission system has higher accuracy, saving feeding time, making operation more efficient.

2.Adopt pipe-plate and multiple pipe welding structure or Triangle structure. Strong shock absorption and wear resistance.

3.Good casting and cutting performance. Excellent lubricity, corrosion resistance and dimensional stability.

4.Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using, so the machine accuracy could maintain for a long time, and no deformation in a life cycle.

1.With the professional automatci type seting software ,the cutting plate availability increase 1%-5%,cutting productivity

10%-30%,significantly improve the cut quality ,process data management,data collection and statistics and other data management functions, visualization integrated interface, simple operation ,easy to learn CNC controller is the most widely used and the most sophisticated controller.

2. It is high speed response , mainly used in high-level laser cutting machine. its processing technology and the powerful graphics editing features are very reliable and

practical, extremely High precision.

1.Tempering process

2.The structure adopts industrial heavy steel structure, under heat treatment, suffers lower emperature tempering and annealing, won’t deform after long time use.

3.Flake graphite cast iron with a minimum tensile strength of 200 MPa.

The cast aluminum beam ,Smartech laser cutting machine with light weight, good dynamic response, faster acceleration, better comprehensive cutting effect

Equipment work and environmental requirements

Requirement | |

1 | Cutting with auxiliary gas: Clean, dry compressed air and high purity oxygen (O2) and nitrogen (N2) ,purity no less than 99.9% purity |

2 | The compressed air supply device (1) the rated pressure: 14 bar (2)Capacityt: 1 m3 |

We would provide English Version working manual.

Service

Lifetime after sale service.

Machine warranty: 5 years.(For any questions during warranty period,we would send new parts to you for free!)

On-site training is both available at buyers’ place or seller’s factory

If you have any questions during using and maintaining,our engineers who could speak very good english would answer you online or by calls.

If your machine has big problems if by any chance,our engineers would arrive your place to debug and fix.

Could be remote control at anytime if needed.

Lifetime 24 hours after sale service.

machine recommendation