| Availability: | |

|---|---|

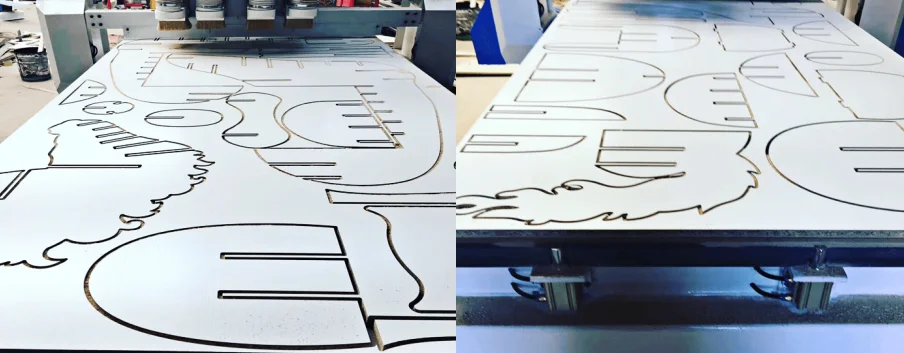

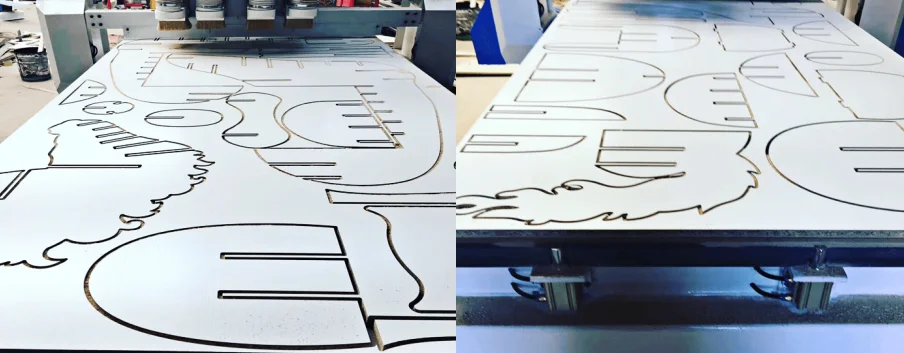

SWP Series 1325-4 3 Axis CNC Router

SMARTECH

New Product

2500x1300x200mm

380V

red

Vacuum table with pop-pin

system for materials location Strong heavy duty body auto feeding roller

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A: Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways? A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China, about 2hours train from Beijing and Shanghai.

-Q Can I arrange sample for cutting test?

A:Yes, always welcome.

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95% customers can learn by themselve

Vacuum table with pop-pin

system for materials location Strong heavy duty body auto feeding roller

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A: Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways? A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China, about 2hours train from Beijing and Shanghai.

-Q Can I arrange sample for cutting test?

A:Yes, always welcome.

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95% customers can learn by themselve