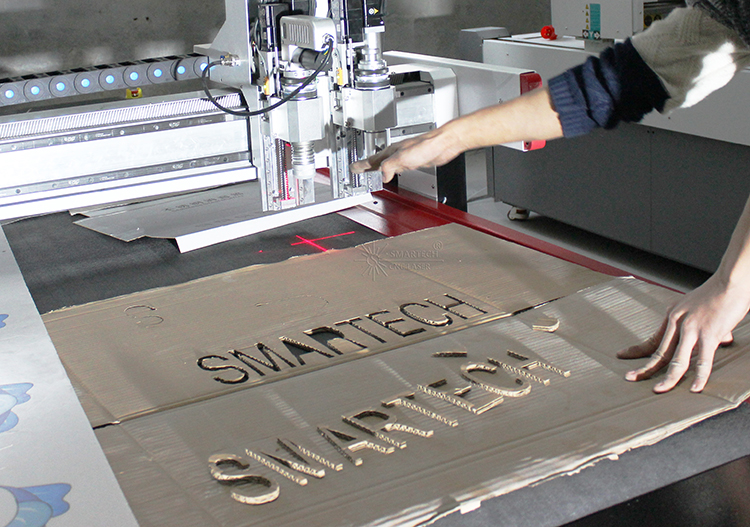

CNC Oscillating Knife Machine For Leather/bags/garment/fabric/pvc/carpet/cloth/kt board

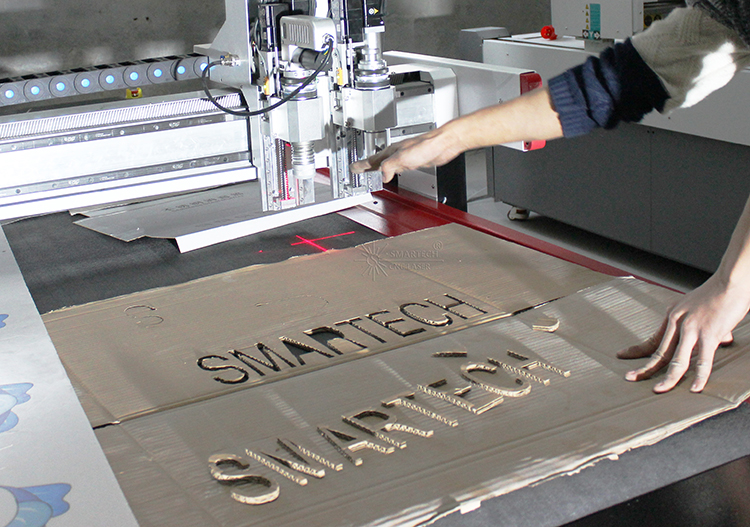

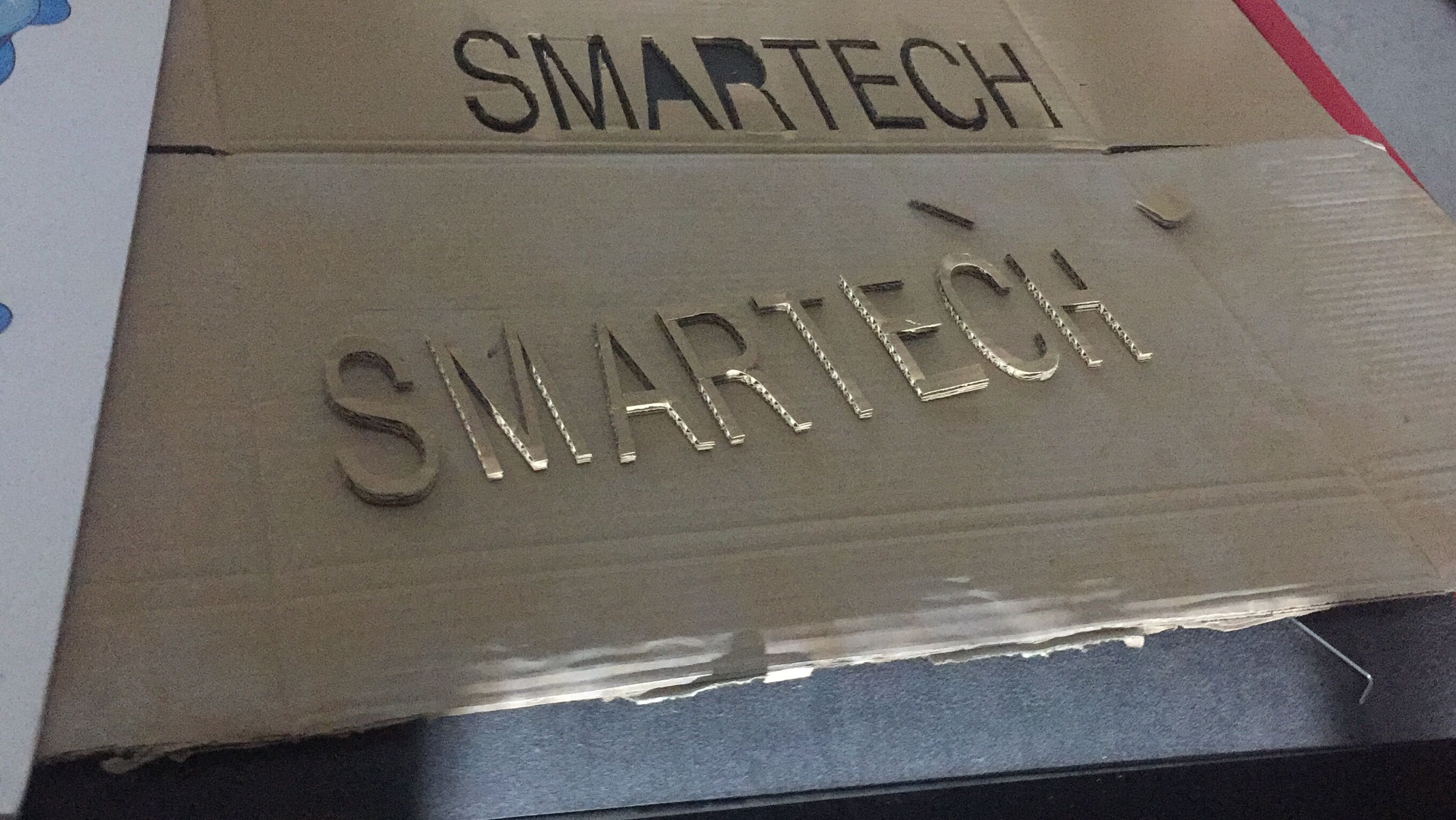

SMARTECH

3600*2280*1600

1100W

red

CNC Oscillating Knife Machine For Leather/bags/garment/fabric/pvc/carpet/cloth/kt board

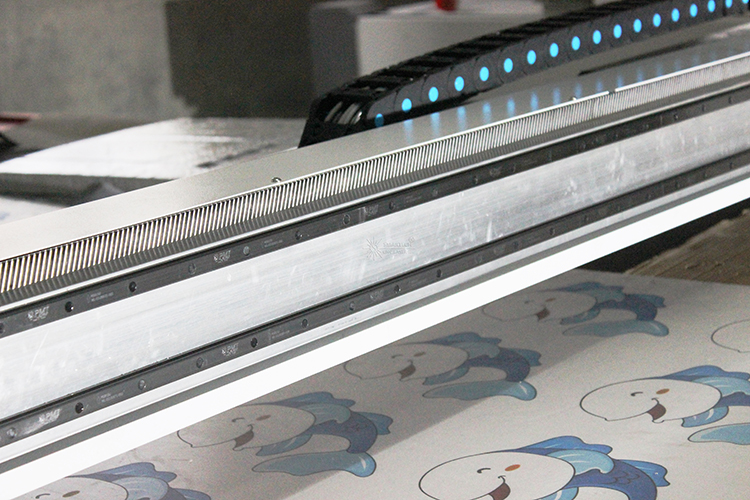

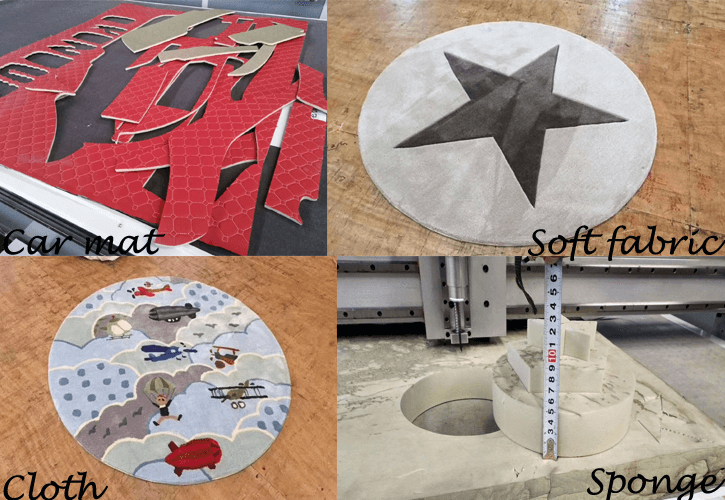

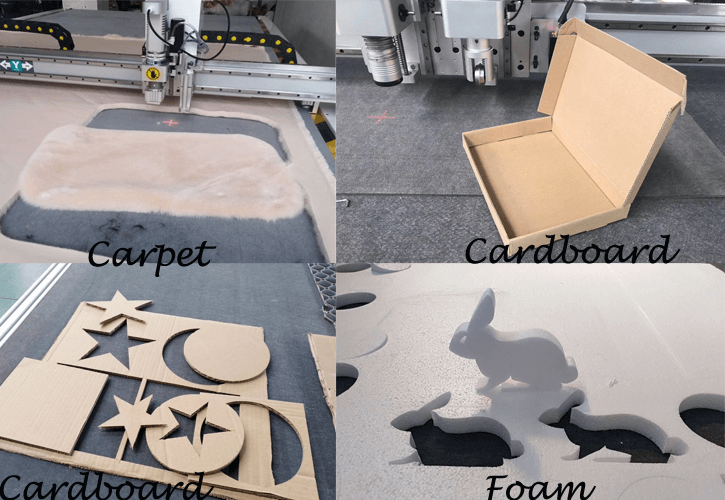

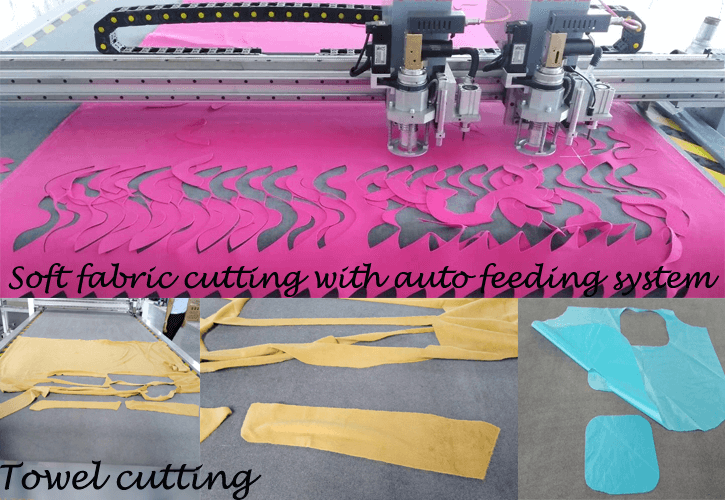

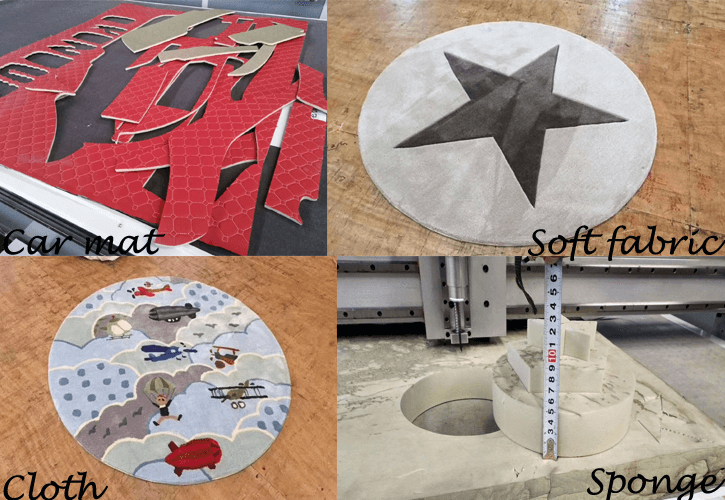

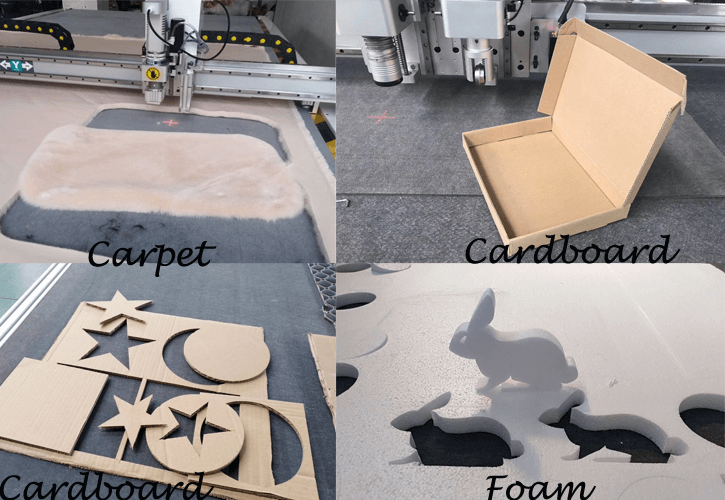

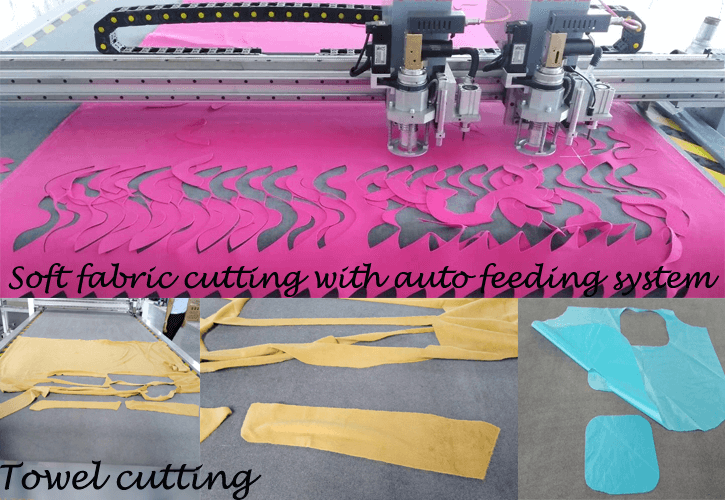

Applicable materials

Leather, cardboard, paper honeycomb, corrugated cardboard, glass fiber, carbon fiber, sticker, film, KT-board, foam board, acrylic board, rubber, cloth, fabric, gasket material, garment cloth, footwear materials, bags materials, non-woven fabrics, carpets materials, car mat materials, sponge, PU, EVA, XPE, PVC, PP,PE, PTFE, ETFE and composites.

Advantages

SMARTECH CNC oscillating knife leather cutting machine is designed for production with small quantities and can save Features: Automatic CNC Oscillating Knife Cutting Fabric Leather PVC Cutter Machines for sale

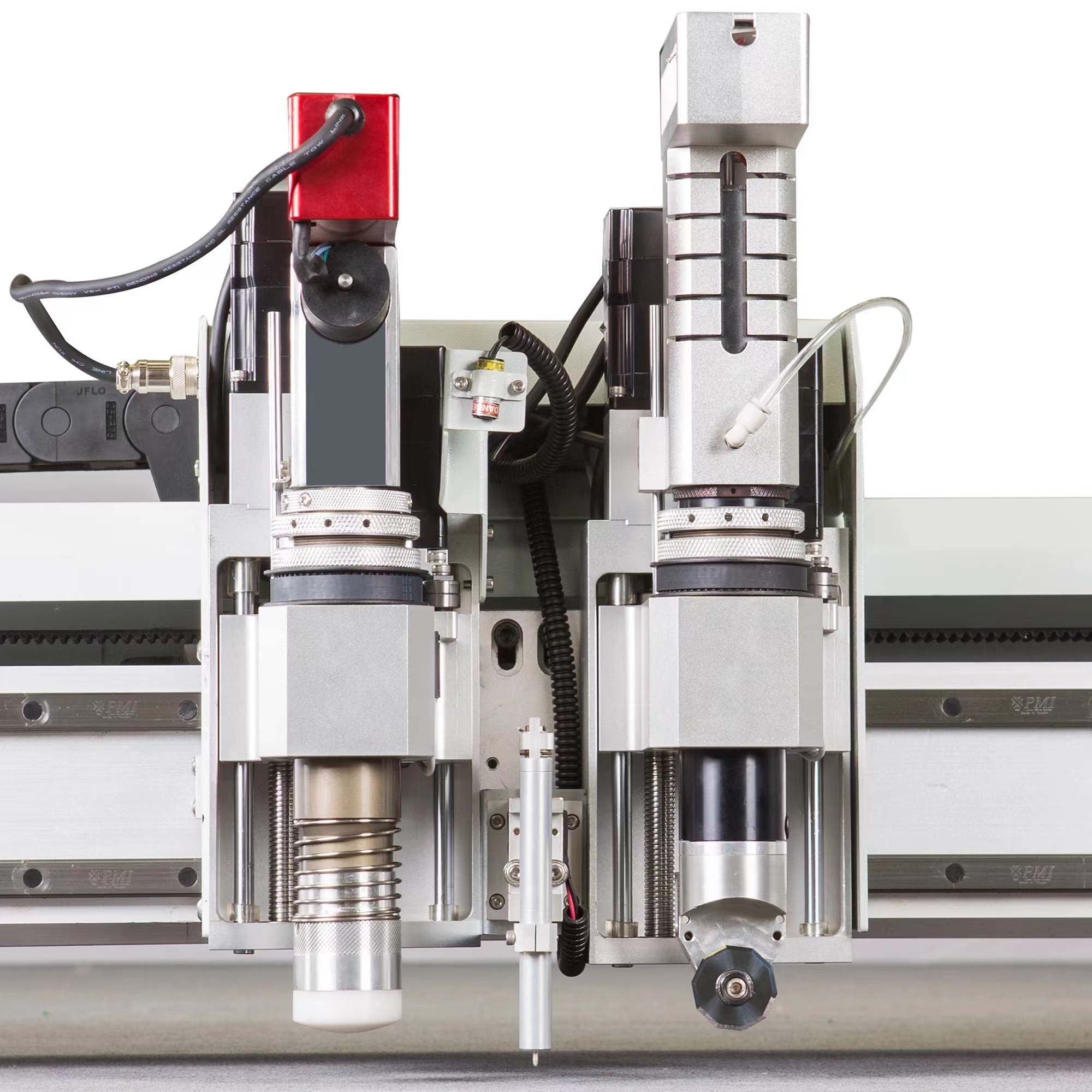

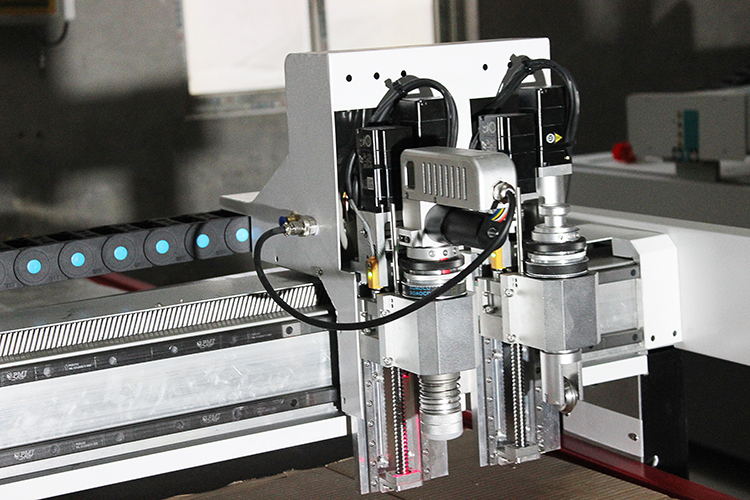

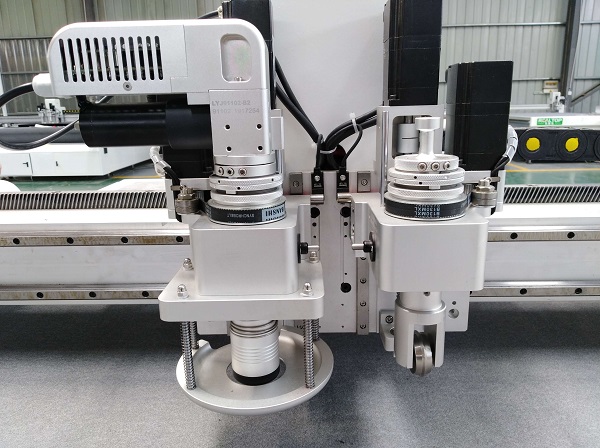

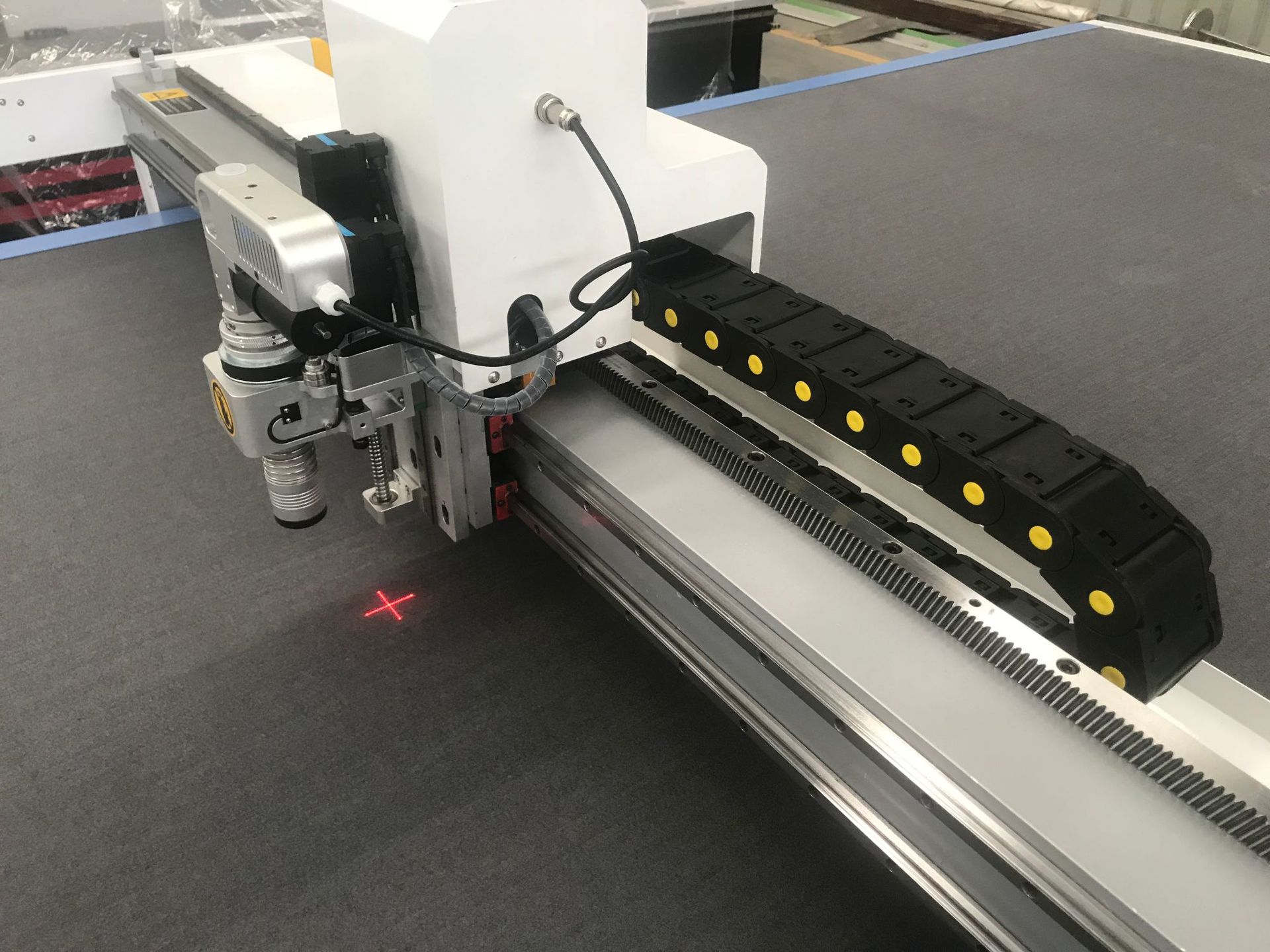

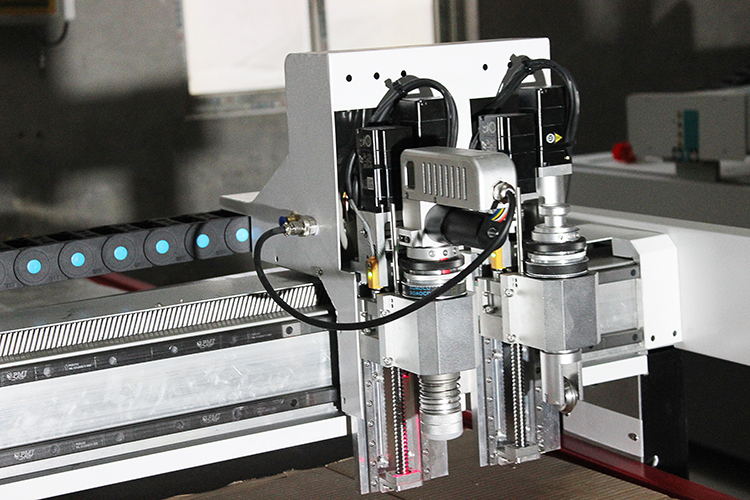

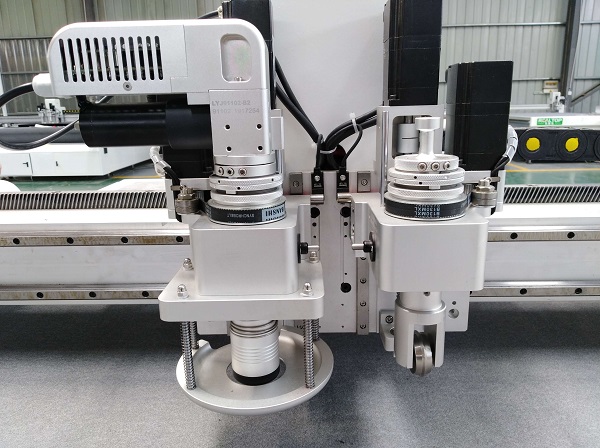

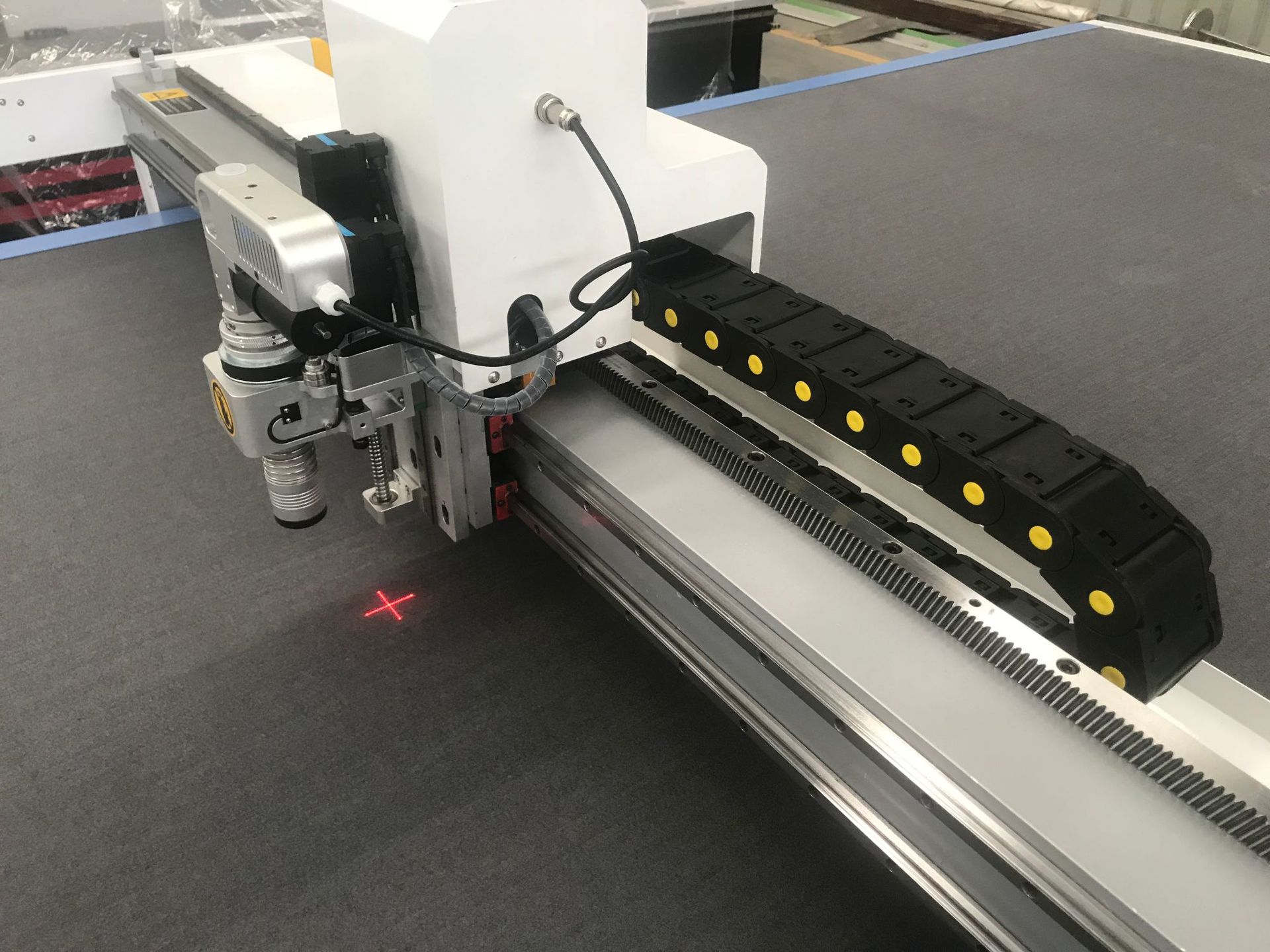

1. Imported Taiwan square linear guide and Japanese servo motor ensure high accuracy, fast cutting speed and stable working performance;

2. Whole machine is welded with thick square seamless steel structure and treated with high temperature, ensures high accuracy, no deformation and super long service life;

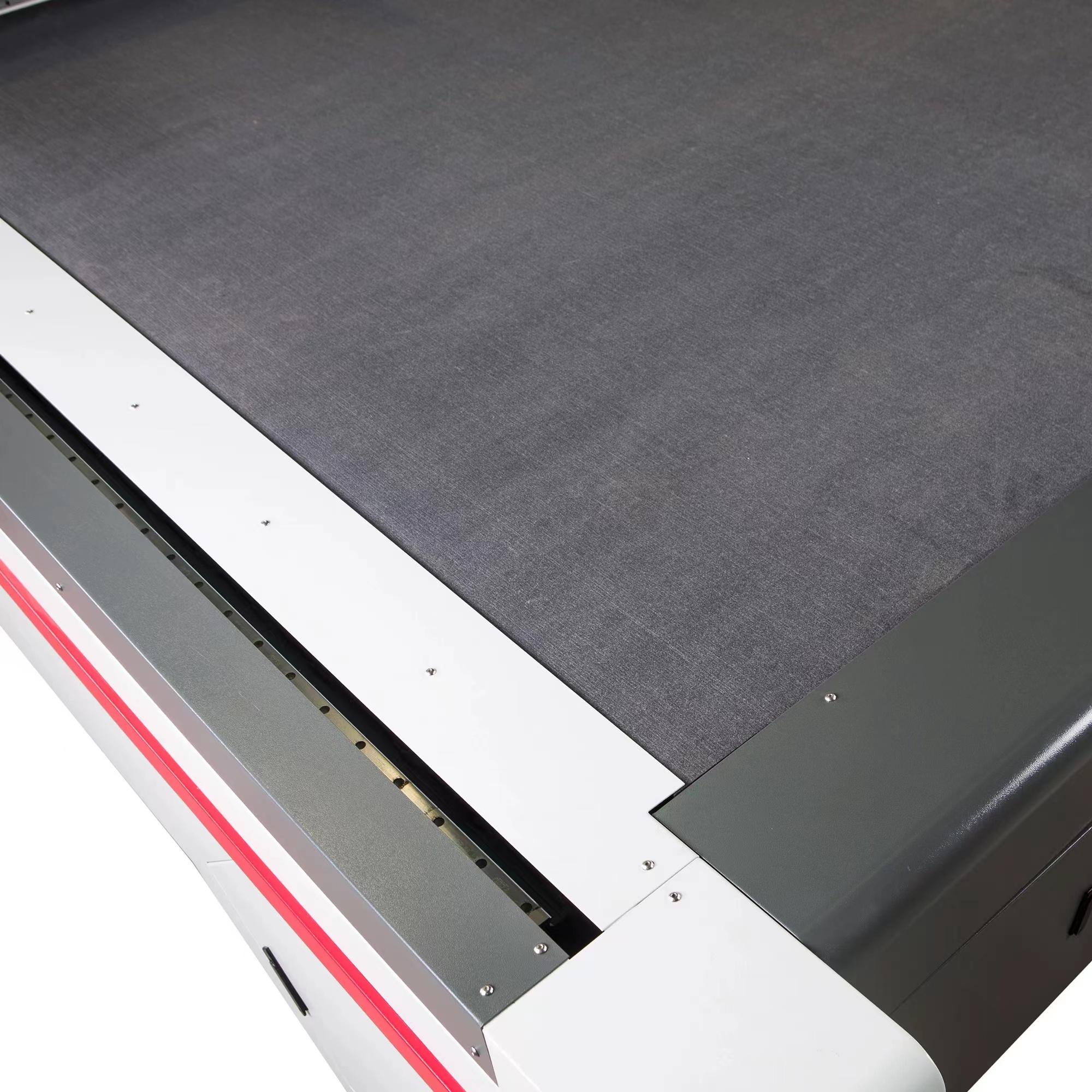

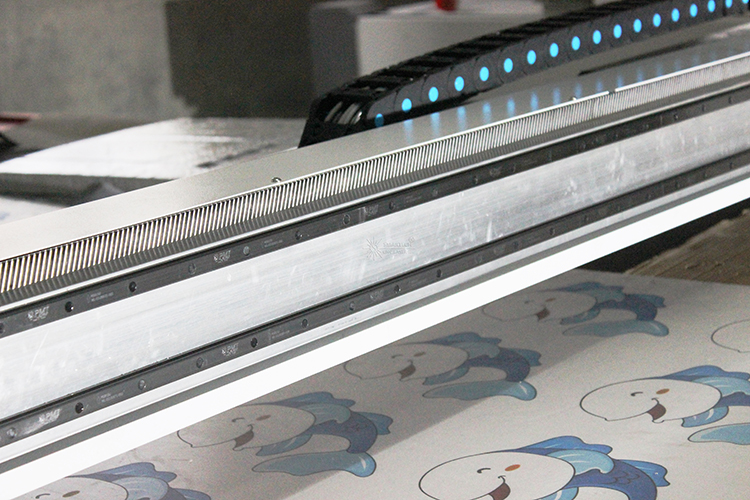

3. The whole piece aluminum platform is honeycomb structure, not easy to deform, sound-absorbing, etc.

4. SMARTECH digital cutting machine was designed easy to install, set-up and operate;

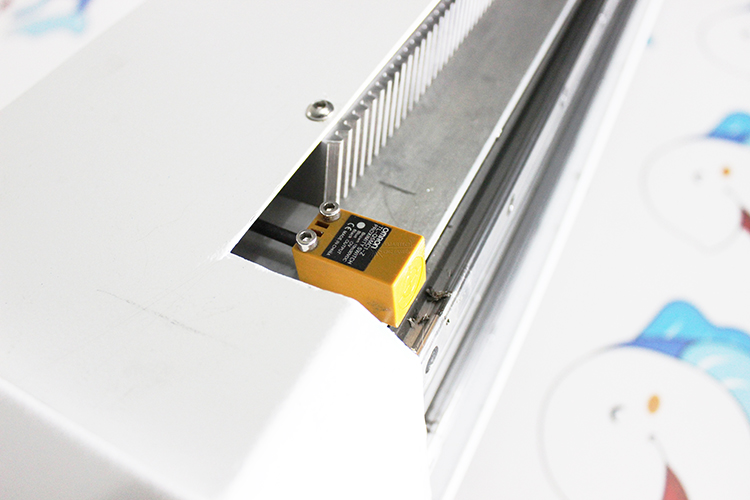

5. Being equipped with infrared sensor and emergency stop devices, guarantees safety;

6. Cutting by knife not laser, no air pollution, no burnt edge, cutting speed is 5-8 times faster than laser cutting machine;

Automatic CNC Oscillating Knife Cutting Fabric Leather PVC Cutter Machines for sale

1. Imported Taiwan square linear guide and Japanese servo motor ensure high accuracy, fast cutting speed and stable working performance;

2. Whole machine is welded with thick square seamless steel structure and treated with high temperature, ensures high accuracy, no deformation and super long service life;

3. The whole piece aluminum platform is honeycomb structure, not easy to deform, sound-absorbing, etc.

4. SMARTECH digital cutting machine was designed easy to install, set-up and operate;

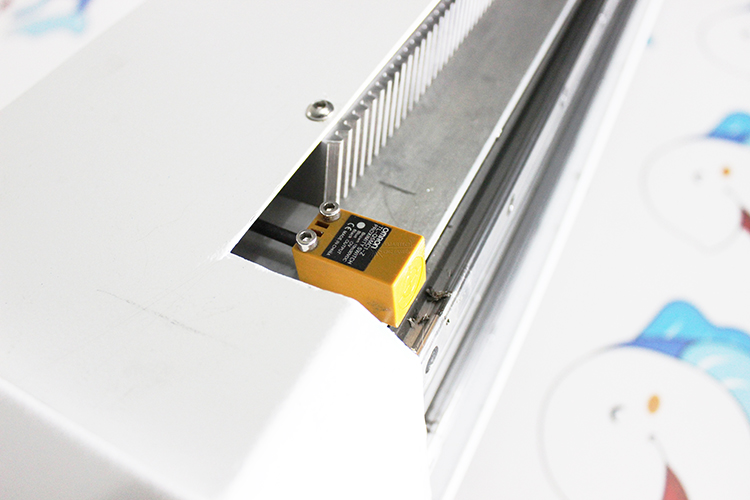

5. Being equipped with infrared sensor and emergency stop devices, guarantees safety;

6. Cutting by knife not laser, no air pollution, no burnt edge, cutting speed is 5-8 times faster than laser cutting machine;

Quotation for CNC knife cutting machine

Model SO-1625 (1600mm*2500mm)

Optional part Auto feeding system

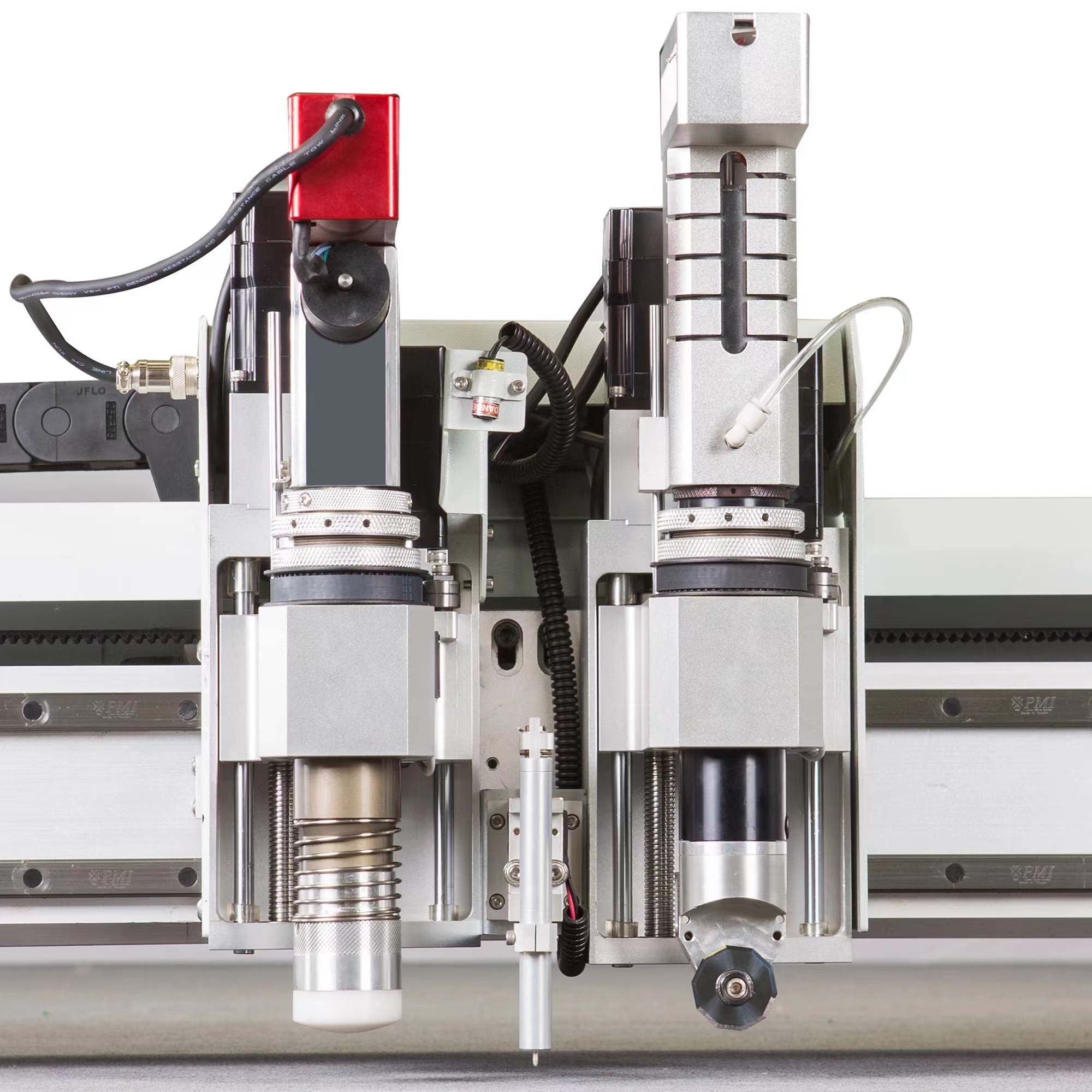

Knife tools include Oscillating knife;V-cut;Increasing tool;CCD camera;Auto feeding system

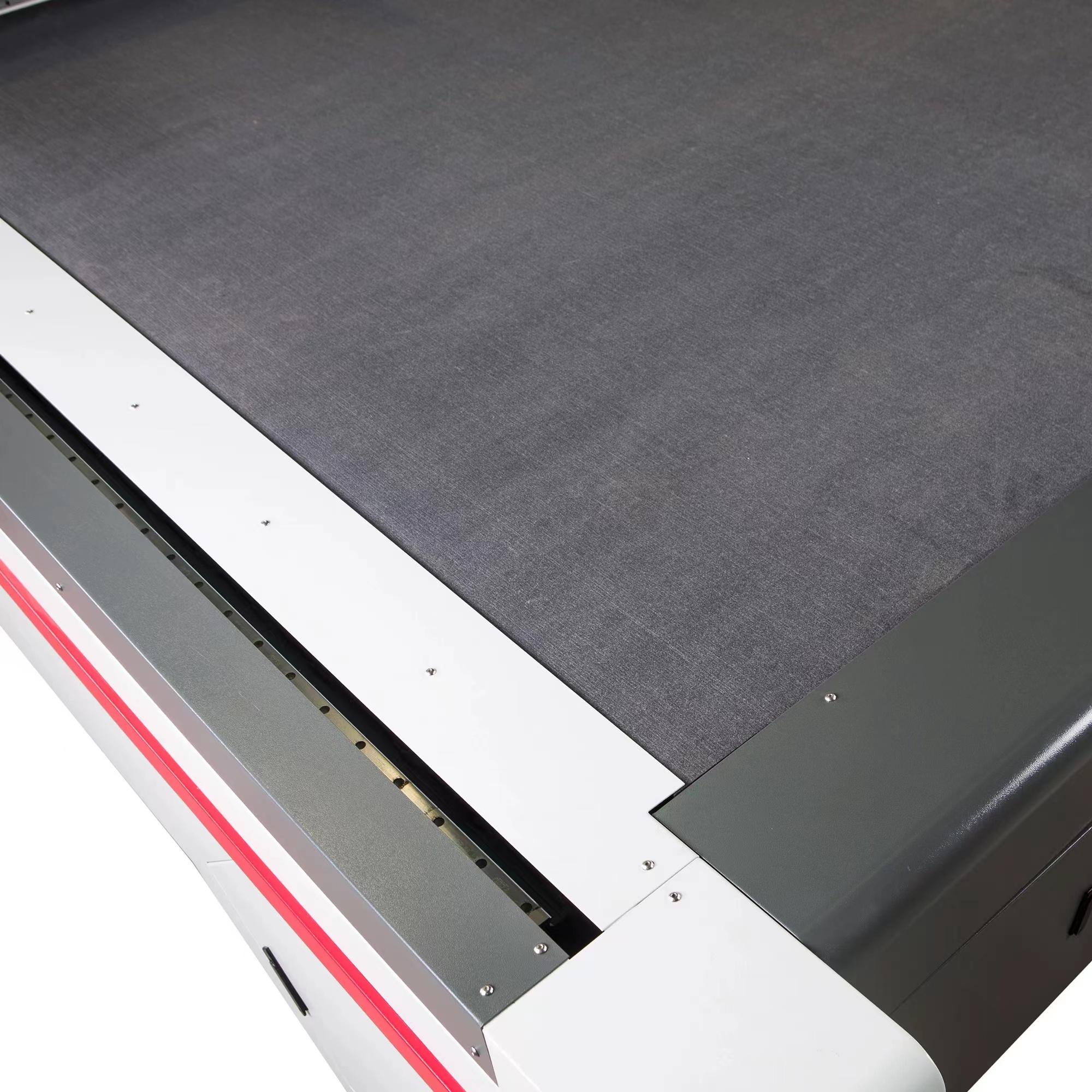

Working table Fixed working table

Working area 1300*2500mm

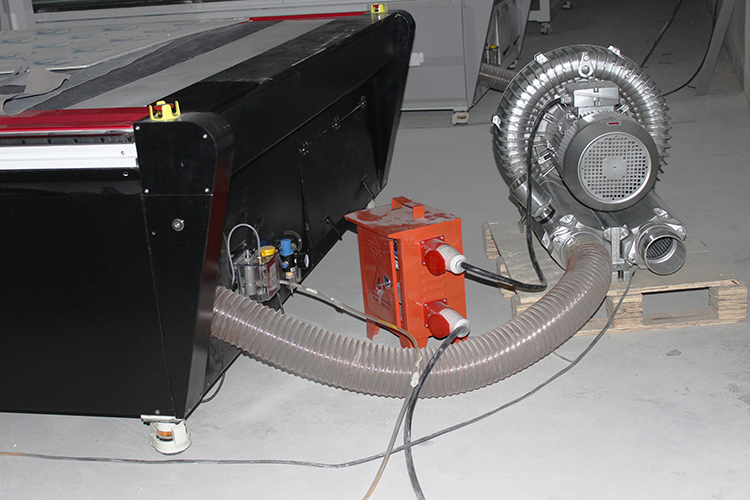

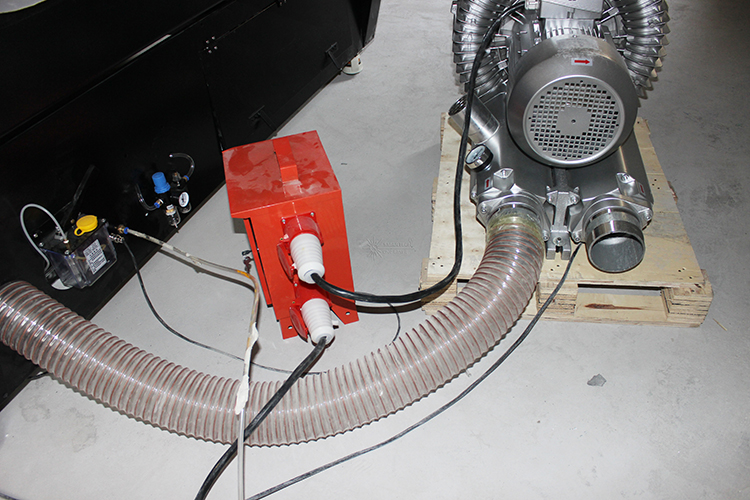

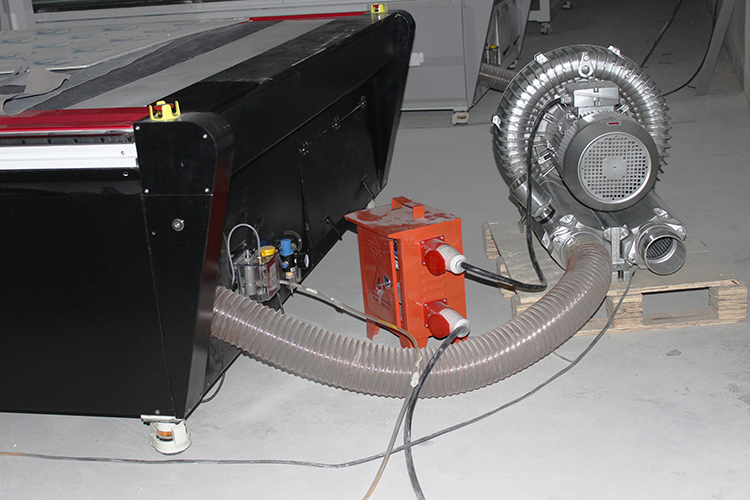

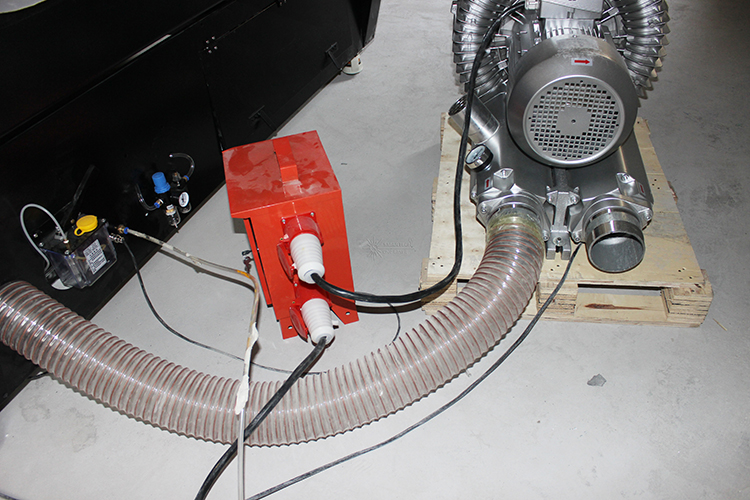

Material fixed way Vacuum suction system

Control system LED Touching screen

Cutting speed 0-1,500mm/s(according to different cutting materials)

Cutting thickness ≤25mm

Cutting accuracy ≤0.1mm

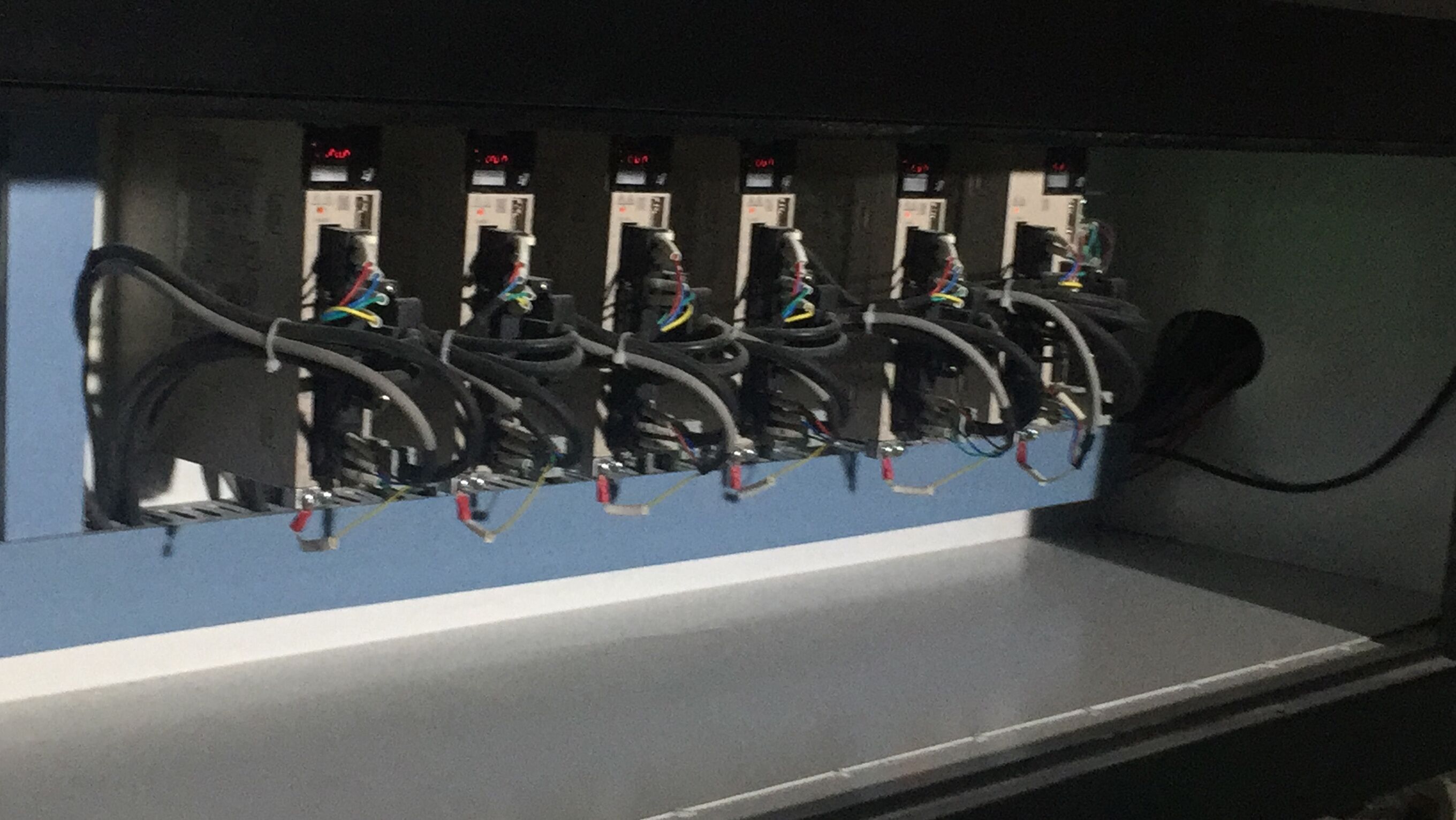

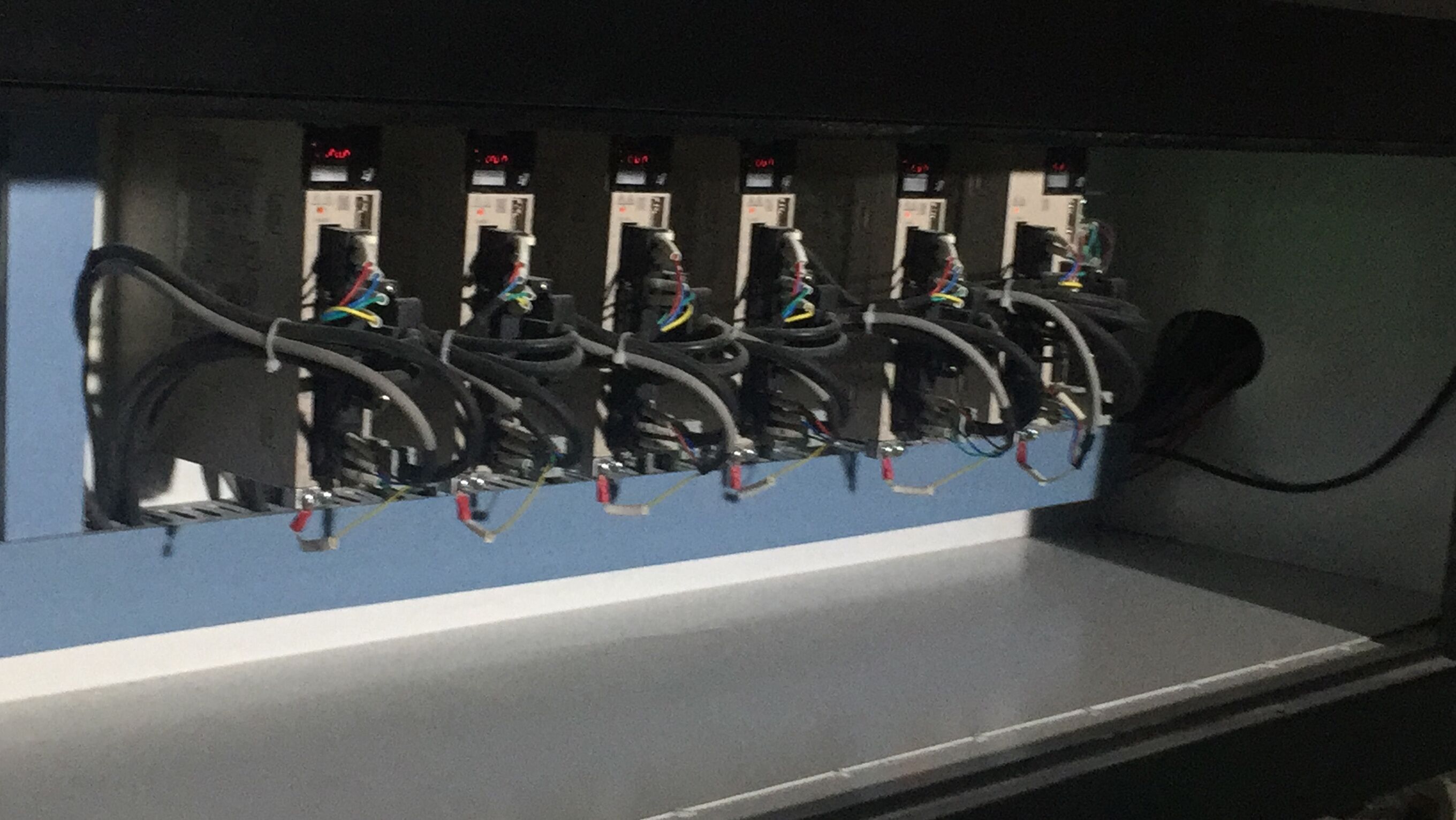

Drive system Yaskawa servo motor and driver

Transmission system PMI linear square rail and Megaoyne belt

Instruction system HP-GL compatible format

Vacuum pump power 9.0KW

Graphic format supported PLT, DXF, AI, etc.

Compatible CORELDRAW, PHOTOSHOP, AUTOCAD, TAJIMA, etc.

Safety device Infrared sensors and emergency stop devices double protection.

Connection Network port

Working voltage AC 220V±10%, 50Hz/60Hz

Package Wooden case

Machine size 3250*2150*1350MM/3050×2100×1350mm(SO1625/SO1325)

Packing Size 3600*2280*1600/3200×2180×1600mm (SO1625/SO1325)

Net weight 1500/1300KGS (SO1625/SO1325)

Gross weight 1700/1500KGS(SO1625/SO1325)

FAQ

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A:Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways?

A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China,about 2hours train from Beijing and Shanghai. -Q Can I arrange sample for cutting test? A:Yes, always welcome.

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95% customers can learn by themselves.

CNC Oscillating Knife Machine For Leather/bags/garment/fabric/pvc/carpet/cloth/kt board

Applicable materials

Leather, cardboard, paper honeycomb, corrugated cardboard, glass fiber, carbon fiber, sticker, film, KT-board, foam board, acrylic board, rubber, cloth, fabric, gasket material, garment cloth, footwear materials, bags materials, non-woven fabrics, carpets materials, car mat materials, sponge, PU, EVA, XPE, PVC, PP,PE, PTFE, ETFE and composites.

Advantages

SMARTECH CNC oscillating knife leather cutting machine is designed for production with small quantities and can save Features: Automatic CNC Oscillating Knife Cutting Fabric Leather PVC Cutter Machines for sale

1. Imported Taiwan square linear guide and Japanese servo motor ensure high accuracy, fast cutting speed and stable working performance;

2. Whole machine is welded with thick square seamless steel structure and treated with high temperature, ensures high accuracy, no deformation and super long service life;

3. The whole piece aluminum platform is honeycomb structure, not easy to deform, sound-absorbing, etc.

4. SMARTECH digital cutting machine was designed easy to install, set-up and operate;

5. Being equipped with infrared sensor and emergency stop devices, guarantees safety;

6. Cutting by knife not laser, no air pollution, no burnt edge, cutting speed is 5-8 times faster than laser cutting machine;

Automatic CNC Oscillating Knife Cutting Fabric Leather PVC Cutter Machines for sale

1. Imported Taiwan square linear guide and Japanese servo motor ensure high accuracy, fast cutting speed and stable working performance;

2. Whole machine is welded with thick square seamless steel structure and treated with high temperature, ensures high accuracy, no deformation and super long service life;

3. The whole piece aluminum platform is honeycomb structure, not easy to deform, sound-absorbing, etc.

4. SMARTECH digital cutting machine was designed easy to install, set-up and operate;

5. Being equipped with infrared sensor and emergency stop devices, guarantees safety;

6. Cutting by knife not laser, no air pollution, no burnt edge, cutting speed is 5-8 times faster than laser cutting machine;

Quotation for CNC knife cutting machine

Model SO-1625 (1600mm*2500mm)

Optional part Auto feeding system

Knife tools include Oscillating knife;V-cut;Increasing tool;CCD camera;Auto feeding system

Working table Fixed working table

Working area 1300*2500mm

Material fixed way Vacuum suction system

Control system LED Touching screen

Cutting speed 0-1,500mm/s(according to different cutting materials)

Cutting thickness ≤25mm

Cutting accuracy ≤0.1mm

Drive system Yaskawa servo motor and driver

Transmission system PMI linear square rail and Megaoyne belt

Instruction system HP-GL compatible format

Vacuum pump power 9.0KW

Graphic format supported PLT, DXF, AI, etc.

Compatible CORELDRAW, PHOTOSHOP, AUTOCAD, TAJIMA, etc.

Safety device Infrared sensors and emergency stop devices double protection.

Connection Network port

Working voltage AC 220V±10%, 50Hz/60Hz

Package Wooden case

Machine size 3250*2150*1350MM/3050×2100×1350mm(SO1625/SO1325)

Packing Size 3600*2280*1600/3200×2180×1600mm (SO1625/SO1325)

Net weight 1500/1300KGS (SO1625/SO1325)

Gross weight 1700/1500KGS(SO1625/SO1325)

FAQ

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A:Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways?

A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China,about 2hours train from Beijing and Shanghai. -Q Can I arrange sample for cutting test? A:Yes, always welcome.

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95% customers can learn by themselves.