| Availability: | |

|---|---|

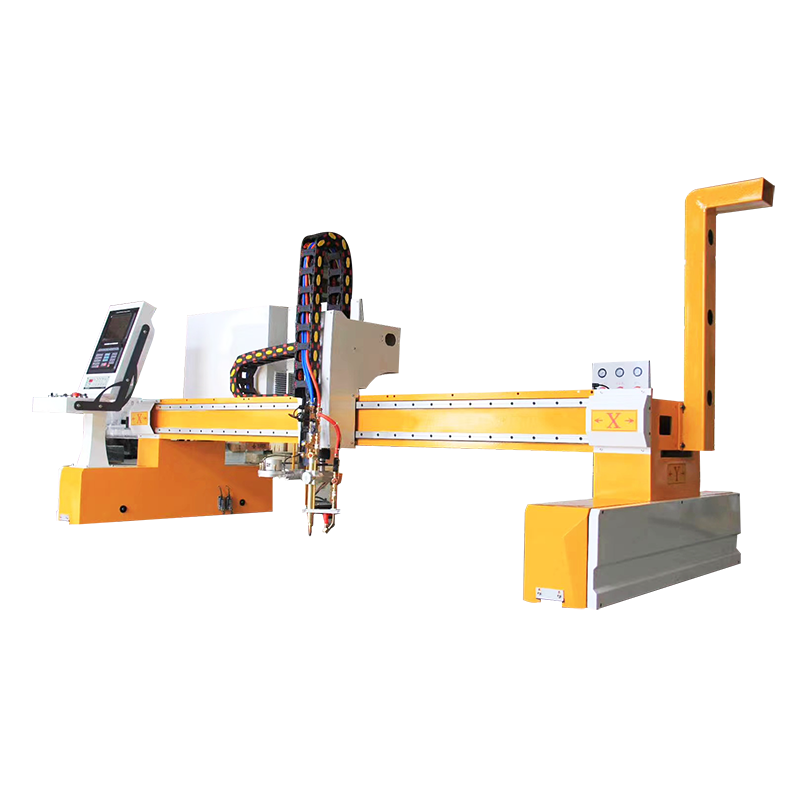

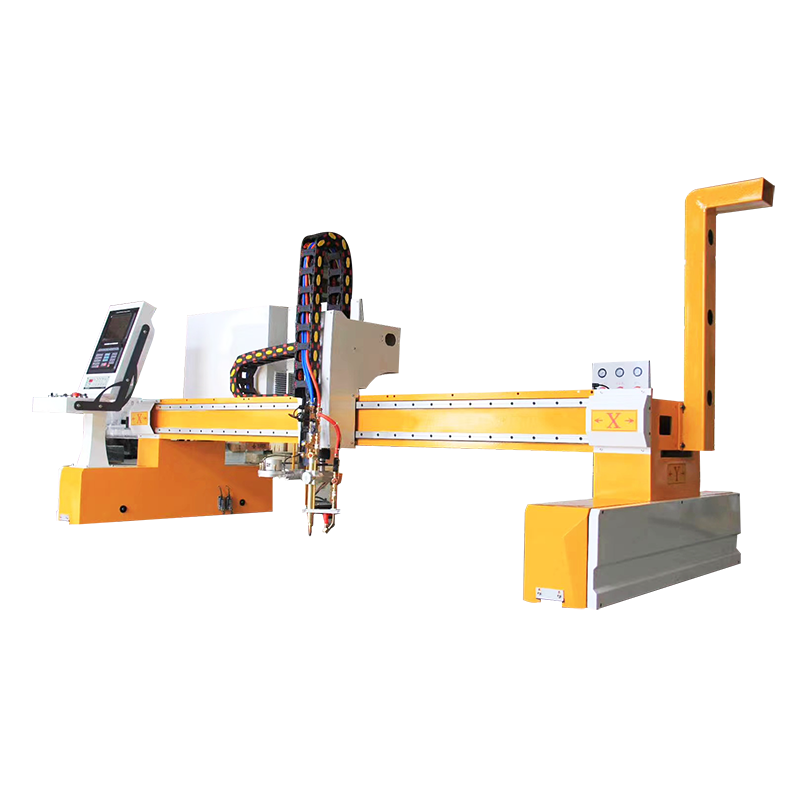

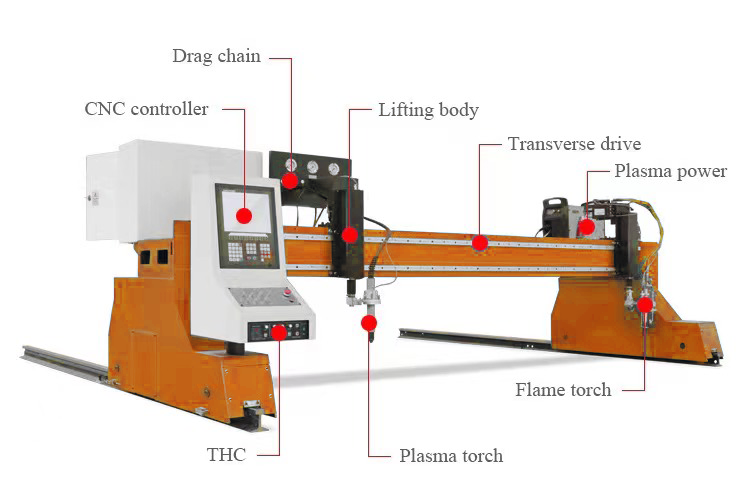

SP-1530 Plasma + Flame cutter

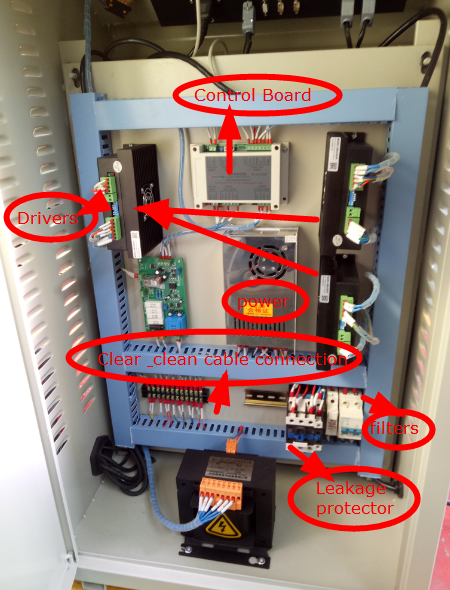

SMARTECH

Stepper Motor

1300x2500/1500x3000mm

380V

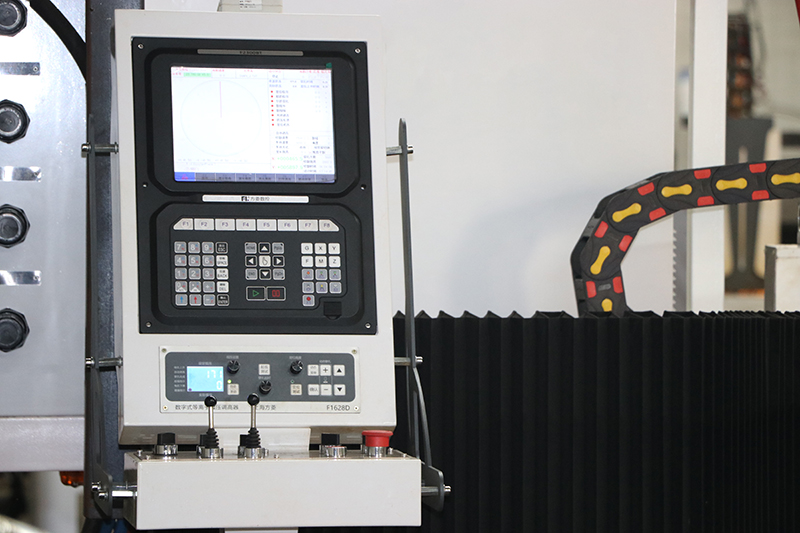

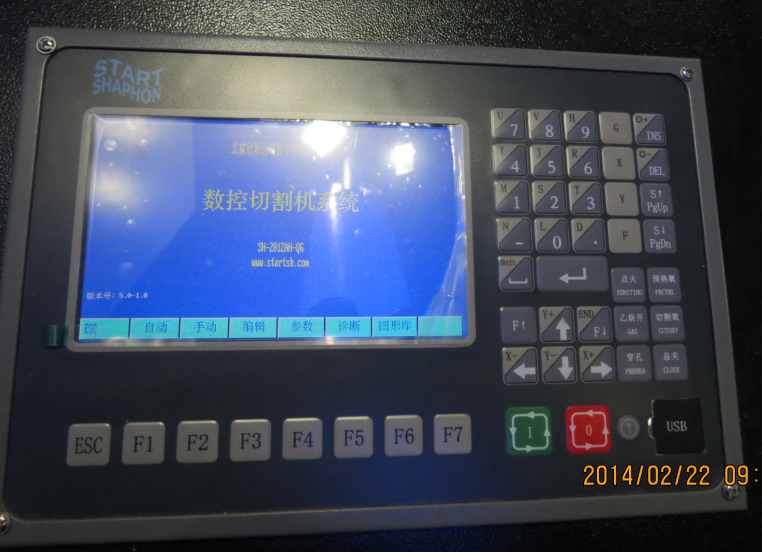

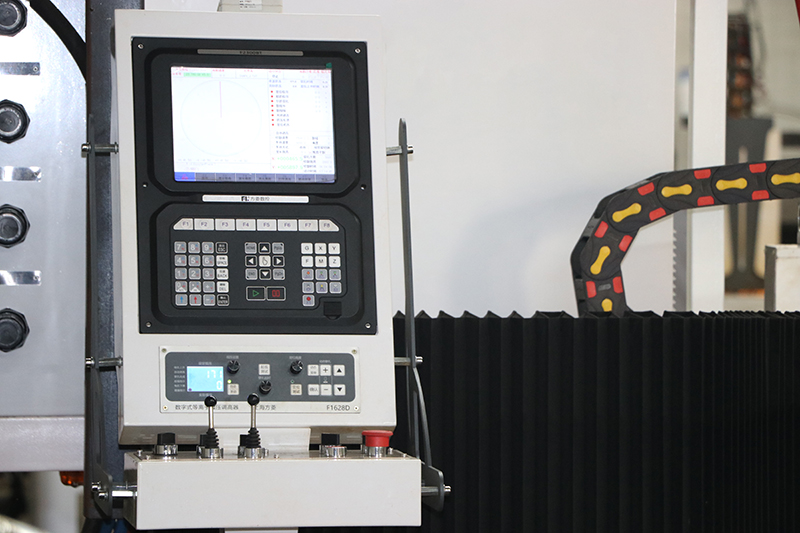

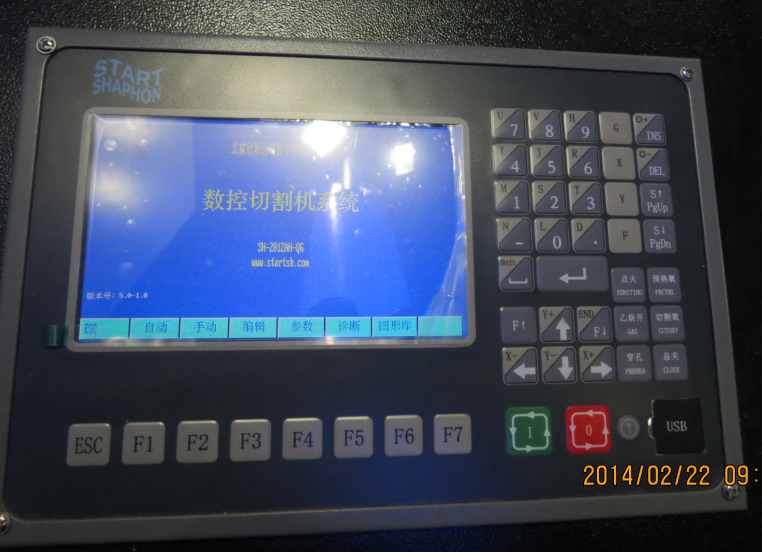

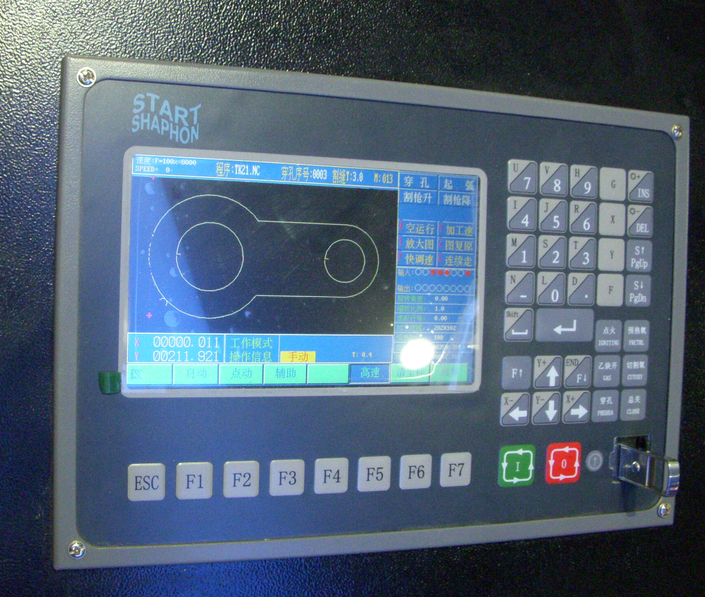

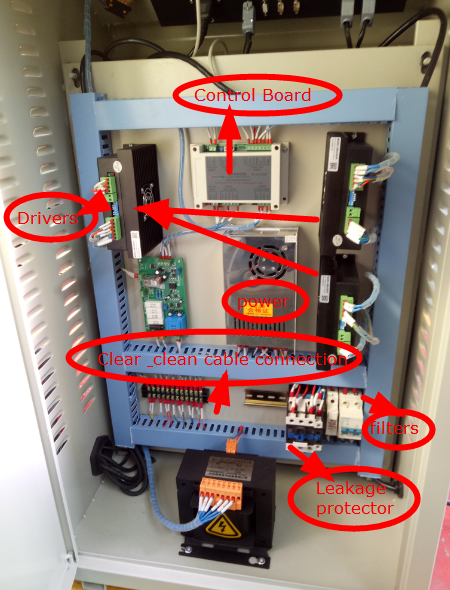

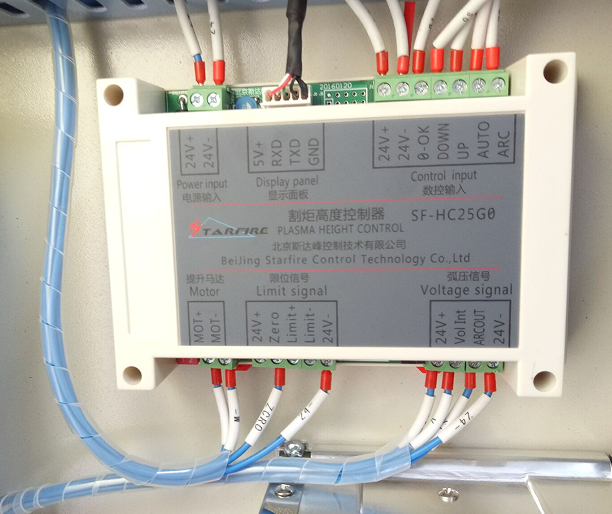

1. Display: 5-inch LCD monitor

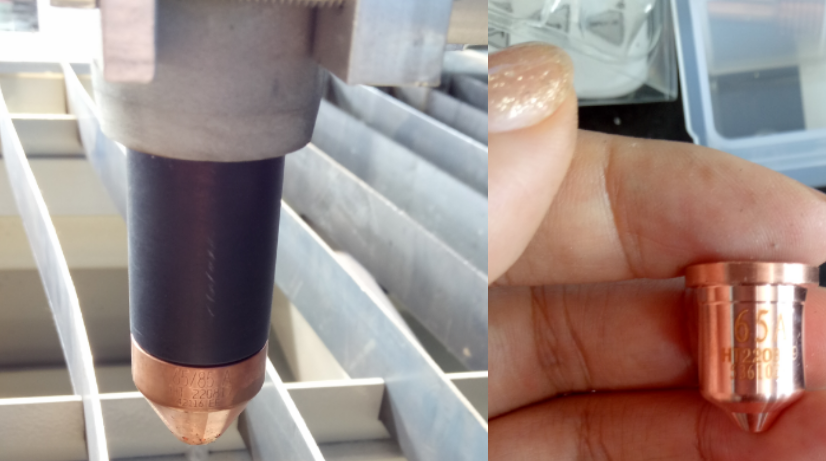

2, external interface: USB

3, buttons and chassis: completely shielded steel structure, anti-electromagnetic radiation, anti-static.

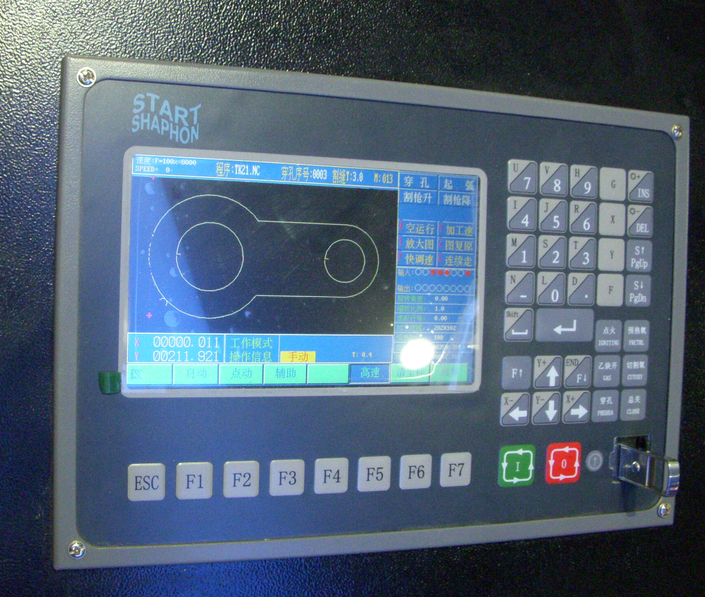

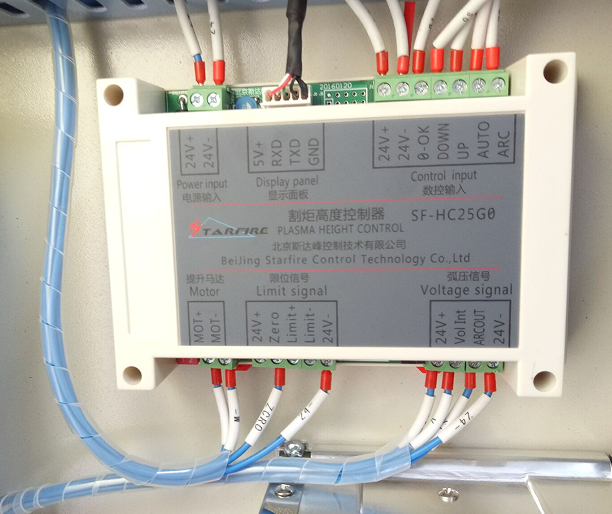

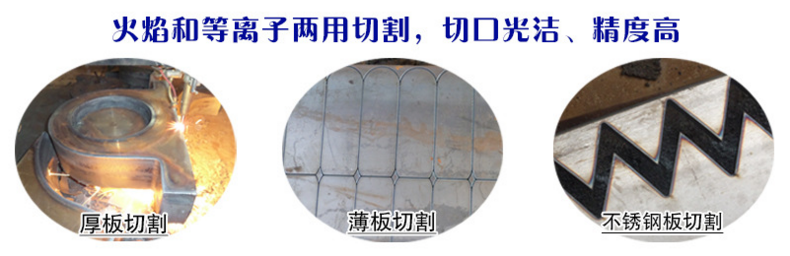

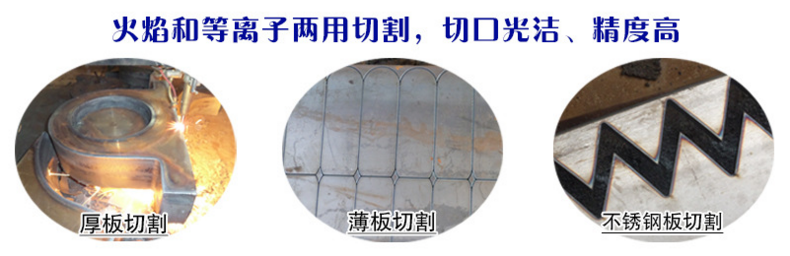

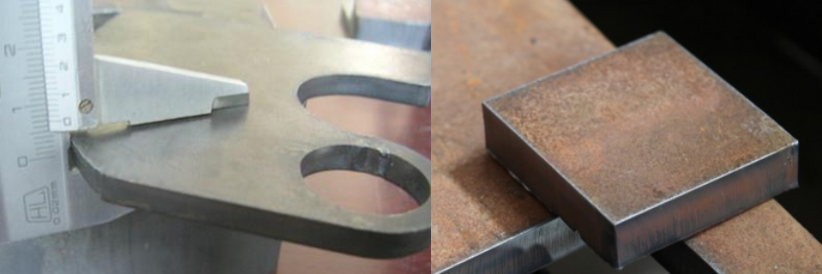

4.Chinese and English prompts on the operation interface. There are various working status indications on the graphic display panel. The digital control and drive adopt modular integrated design. The operation and maintenance are simple and convenient.

5.Automatic Compensation,positioning,break point renewal ,restore Automatically.

6.With a high automation, easy to use, high precision and high reliability.

7.The advantages of easy operation and maintenance are extensively applicable to the cutting of metal sheets in various mechanical manufacturing industries.

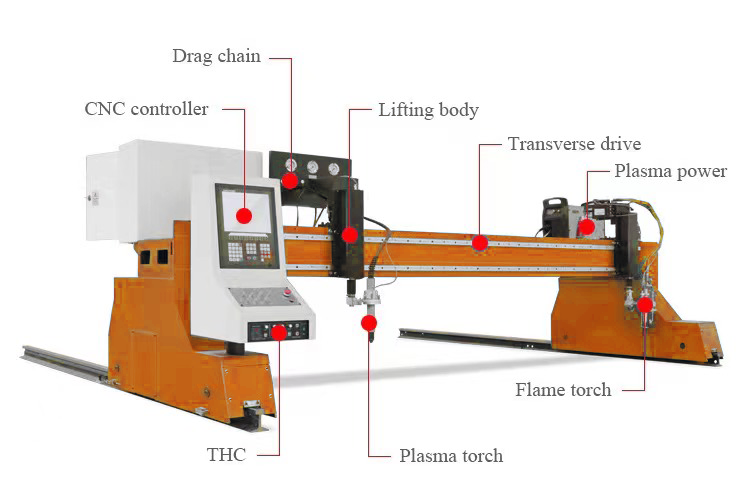

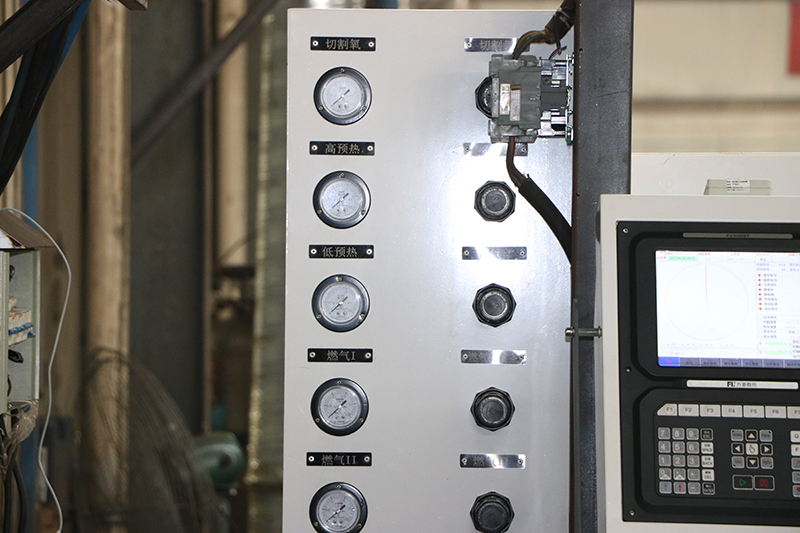

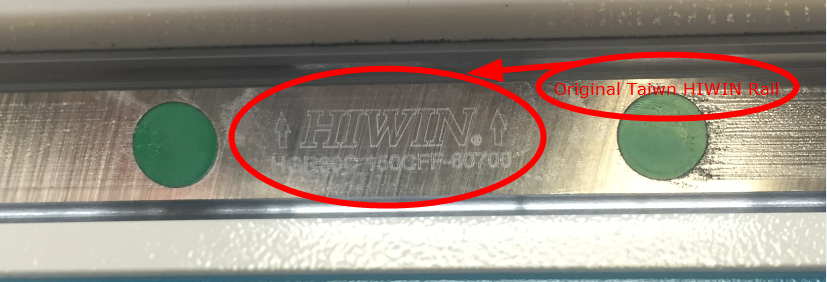

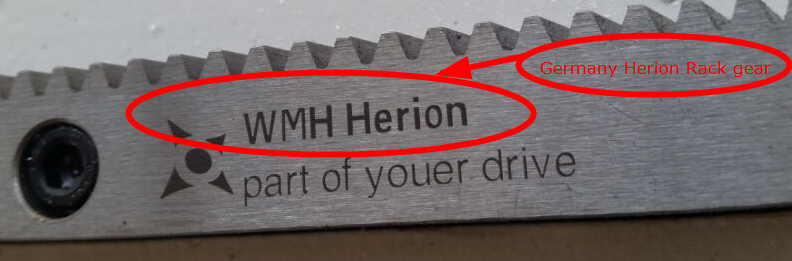

8. It adopts bilateral drive, double-axis linear guide rails, standard transverse guide 4m, vertical rail length 8m, single flame or single plasma cutting mode, automatic ignition;

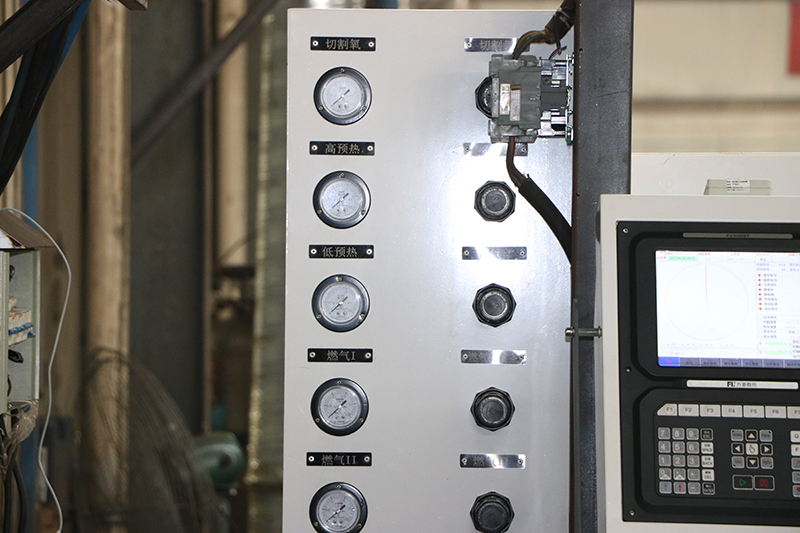

9. Addition to flame and plasma cutting methods. Cross-cutting matching devices can also be configured.

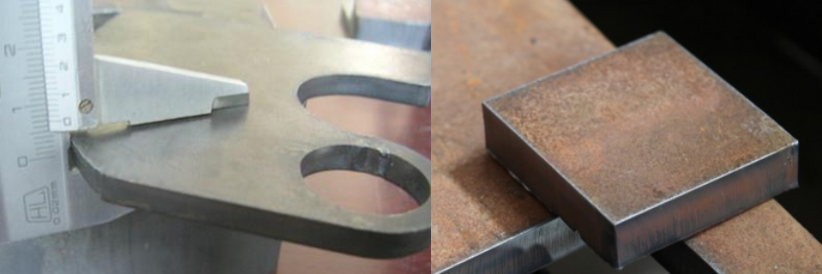

10.Cutting faster, more accurate control, the cutting surface is more smooth, no glitches, no black; cutting holes in high quality.

Main Features

1. Beam with light structural design, the structure has good rigidity, light weight, exercise inertia and low cost.

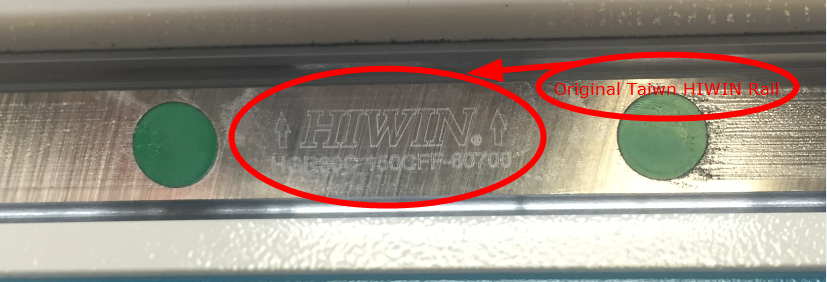

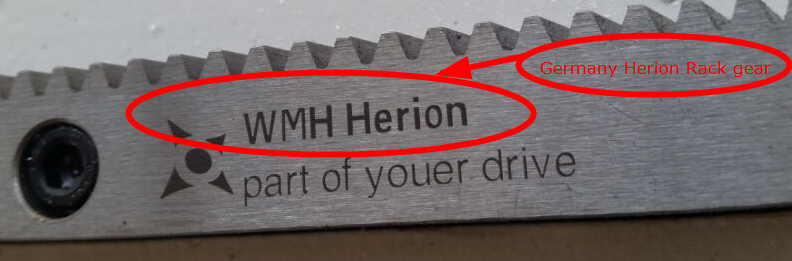

2. Gantry-type structure, Y-axis synchronous dual-motor drive and XYZ axis with circular rail (optional formula-type linear guide), steady transmission, and high accuracy.

3. For advertising solid light, groove metal panel and bottom plate of the word for cutting, cutting accuracy good indicator. If equipped with the U.S. Treasure plasma power can achieve lower laser cutting machine.

4. And other advertising devices(vacuum forming machines, gear cutting machine) to form ad word processing pipeline, completely solve the traditional way of manual processing. Improve efficiency several times.

5. Cutting speed, high accuracy and low cost.

6. CNC system configuration high, automatic arc, stable performance, the success rate of 99% arc.

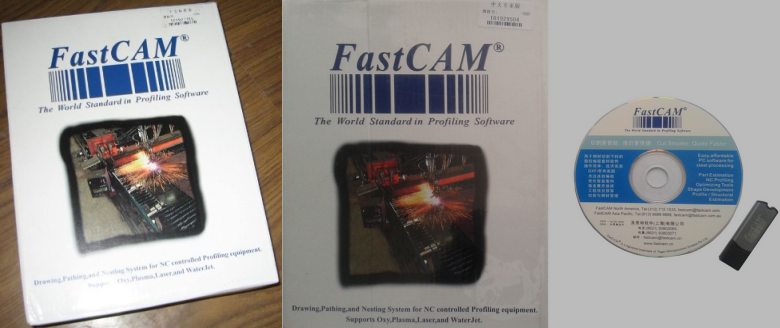

7. Support Wentai, Beihang Haier, ARTCAM, Type3 software such as the standard G code path generated file can also be read by software conversion software such ad AUTOCAD generated DXF formats. U disk exchange control system processing files, easy to operate.

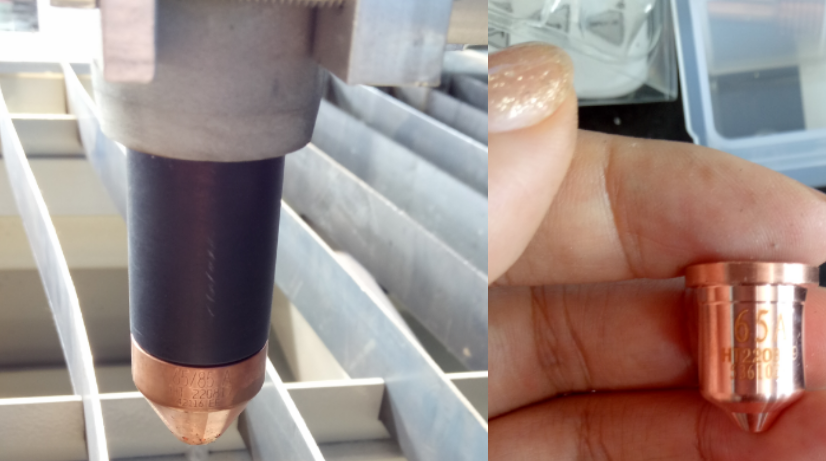

8. Plasma torch power supply and supporting all famous brands, a number of national patents by the manufacturers.

Optional air compressor 0.8MPa

machine recommendation

FAQ

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A:Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways?

A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your

workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China,about 2hours train from Beijing and Shanghai.

-Q Can I arrange sample for cutting test?

A:Yes, always welcome.

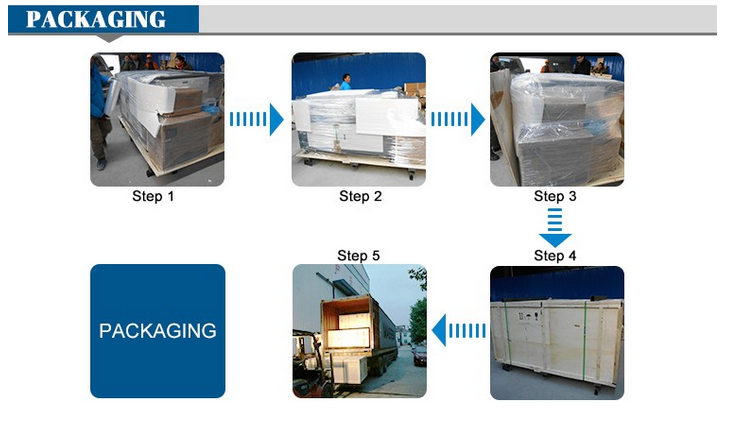

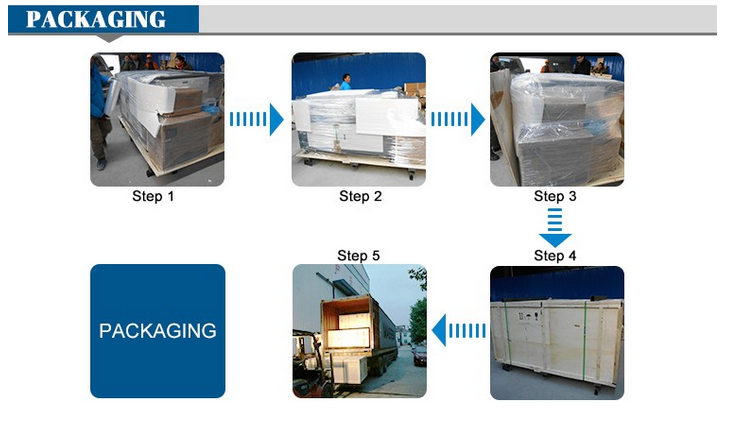

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

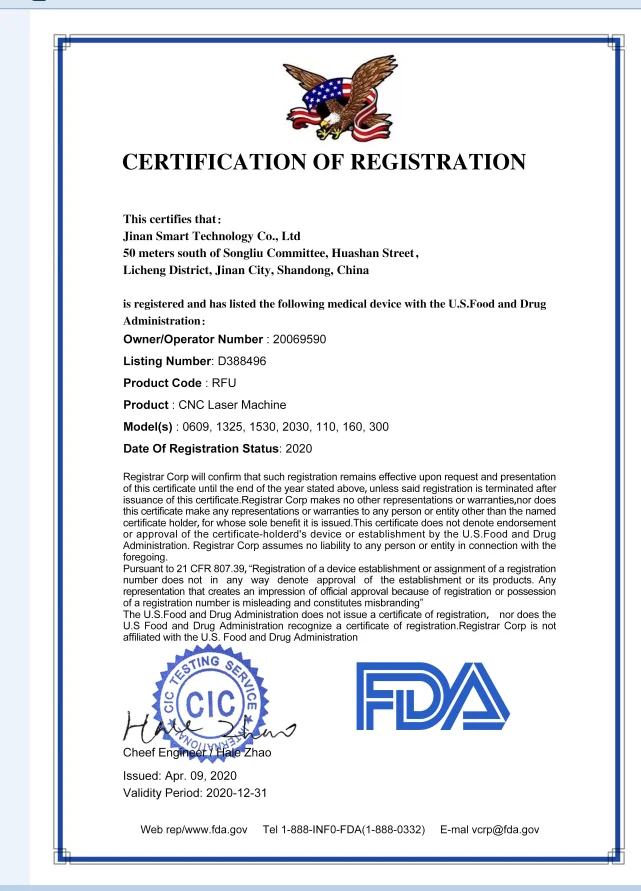

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality

control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95% customers can learn by themselves.

Payment terms

1.30% deposit for production, 70% by T/T after machine production is finished;

Service

@.After sale:

All machine is properly adjusted before dispatch.You will be able to use the machines immediately. If you have any questions during using and maintaining,our engineers who could speak very good english would answer you online or by calls. If you still have troubles on operation or problems,Engineers are also available to give training overseas. Could be remote control if needed. 24 months warranty for the whole machine. Within 24 months under normal use and maintenance, if something is wrong with machine, you will get spare part for free.;You will also get technical support and service all the lifetime.

Quality Guarantee

2 years from delivery date.if your machine has any unintentional damages,we would provide parts for free.

We Could Produce machines according to your specific demands ! We could also provide a OEM manufacturing!

1. Display: 5-inch LCD monitor

2, external interface: USB

3, buttons and chassis: completely shielded steel structure, anti-electromagnetic radiation, anti-static.

4.Chinese and English prompts on the operation interface. There are various working status indications on the graphic display panel. The digital control and drive adopt modular integrated design. The operation and maintenance are simple and convenient.

5.Automatic Compensation,positioning,break point renewal ,restore Automatically.

6.With a high automation, easy to use, high precision and high reliability.

7.The advantages of easy operation and maintenance are extensively applicable to the cutting of metal sheets in various mechanical manufacturing industries.

8. It adopts bilateral drive, double-axis linear guide rails, standard transverse guide 4m, vertical rail length 8m, single flame or single plasma cutting mode, automatic ignition;

9. Addition to flame and plasma cutting methods. Cross-cutting matching devices can also be configured.

10.Cutting faster, more accurate control, the cutting surface is more smooth, no glitches, no black; cutting holes in high quality.

Main Features

1. Beam with light structural design, the structure has good rigidity, light weight, exercise inertia and low cost.

2. Gantry-type structure, Y-axis synchronous dual-motor drive and XYZ axis with circular rail (optional formula-type linear guide), steady transmission, and high accuracy.

3. For advertising solid light, groove metal panel and bottom plate of the word for cutting, cutting accuracy good indicator. If equipped with the U.S. Treasure plasma power can achieve lower laser cutting machine.

4. And other advertising devices(vacuum forming machines, gear cutting machine) to form ad word processing pipeline, completely solve the traditional way of manual processing. Improve efficiency several times.

5. Cutting speed, high accuracy and low cost.

6. CNC system configuration high, automatic arc, stable performance, the success rate of 99% arc.

7. Support Wentai, Beihang Haier, ARTCAM, Type3 software such as the standard G code path generated file can also be read by software conversion software such ad AUTOCAD generated DXF formats. U disk exchange control system processing files, easy to operate.

8. Plasma torch power supply and supporting all famous brands, a number of national patents by the manufacturers.

Optional air compressor 0.8MPa

machine recommendation

FAQ

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A:Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways?

A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your

workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China,about 2hours train from Beijing and Shanghai.

-Q Can I arrange sample for cutting test?

A:Yes, always welcome.

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality

control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95% customers can learn by themselves.

Payment terms

1.30% deposit for production, 70% by T/T after machine production is finished;

Service

@.After sale:

All machine is properly adjusted before dispatch.You will be able to use the machines immediately. If you have any questions during using and maintaining,our engineers who could speak very good english would answer you online or by calls. If you still have troubles on operation or problems,Engineers are also available to give training overseas. Could be remote control if needed. 24 months warranty for the whole machine. Within 24 months under normal use and maintenance, if something is wrong with machine, you will get spare part for free.;You will also get technical support and service all the lifetime.

Quality Guarantee

2 years from delivery date.if your machine has any unintentional damages,we would provide parts for free.

We Could Produce machines according to your specific demands ! We could also provide a OEM manufacturing!