| Availability: | |

|---|---|

SMART-6060B

SMARTECH

1430*1400*2230mm

Technical data

Precision Cutting Product Details | |||

project | Brand | brand location | Specification |

laser source | jpt /Raycus /MAX | shenzhen /wuhan | 1500/2000/3000W |

system | raytool | shanghai | XC3000S |

laser head | raytool | BM110 | |

Pneumatic device | SMC | Japan | ITV10150-312L |

motor | lead shine | shenzhen | ACMOH-0604 |

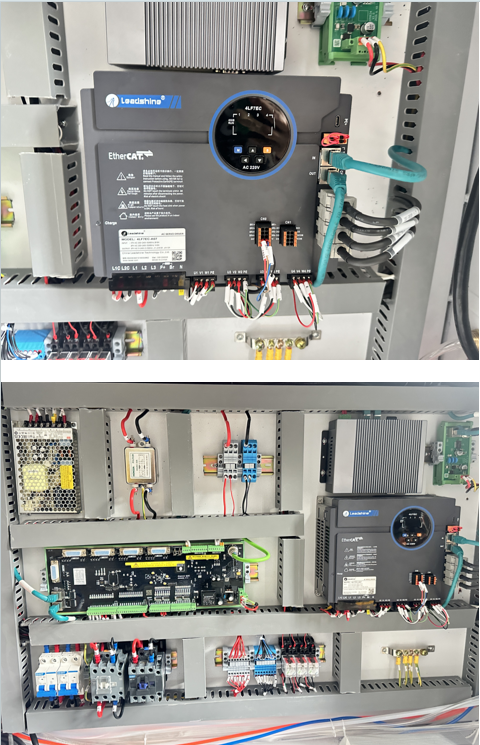

servo system | lead shine | 4LF7EC-A07 | |

module | SKR | koran | X650Y650Z100 |

water chiller | s&a hanli | guangzhou /wuhan | 1500/2000/3000W |

High pressure valve | SMC | Japan | VX232RAXHH |

Electrical components | yijia | zhejiang | Industrial grade |

Machine parts

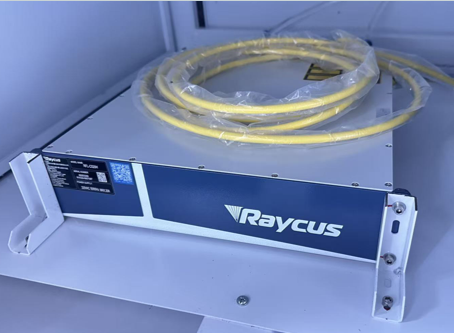

Optical Section-Laser Generator

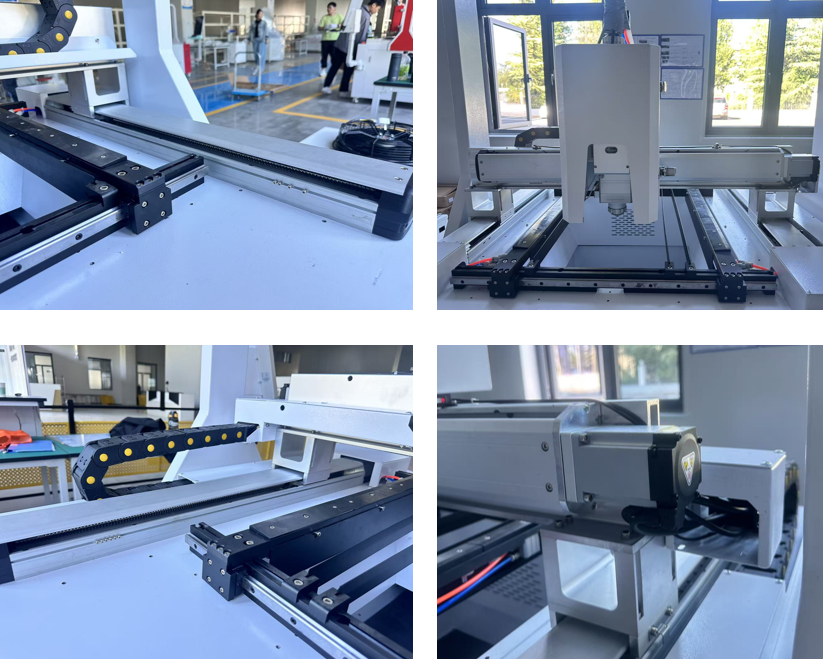

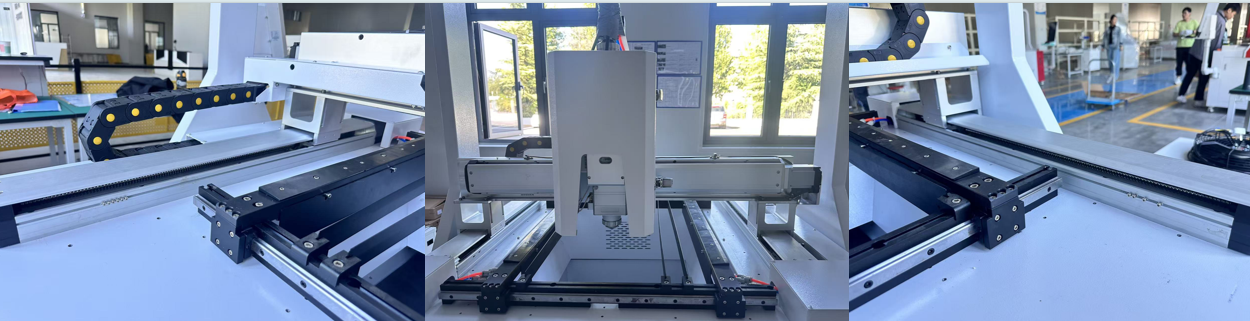

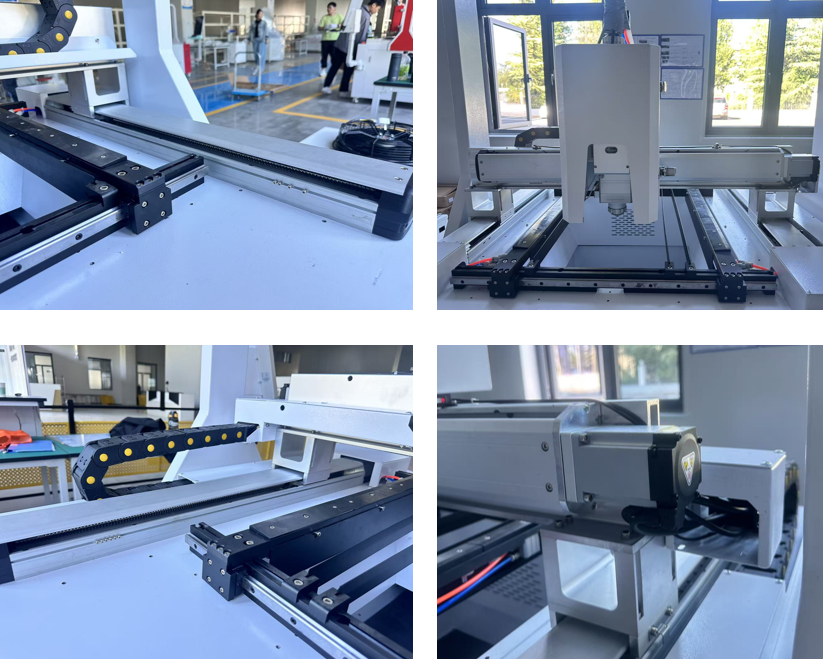

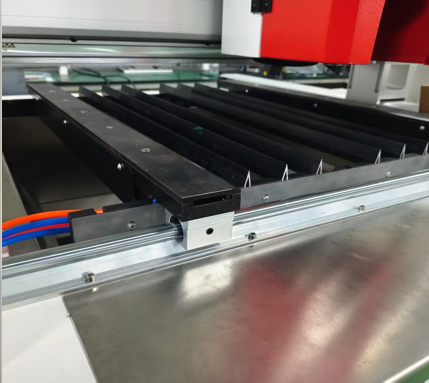

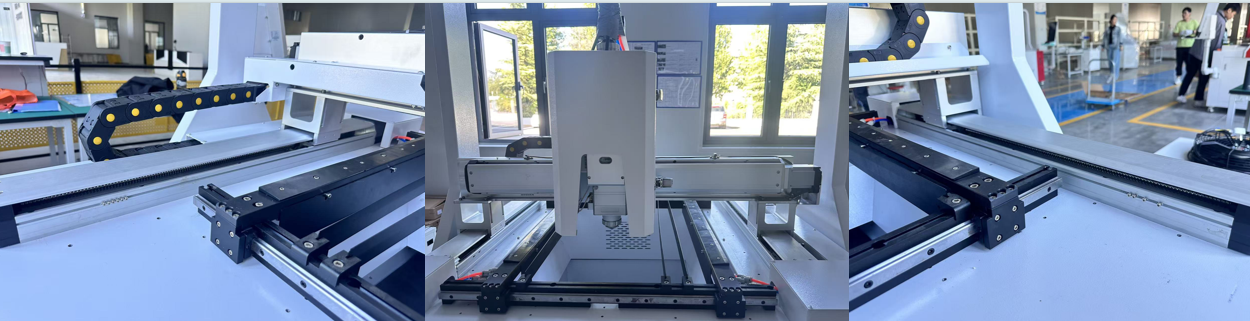

Transmission system

Achieving high-precision linear motion and ensuring transmission stability directly determine the dimensional accuracy and processing efficiency of laser cutting. High transmission efficiency reduces motor energy consumption while allowing for faster and smoother axis movement, thus improving cutting efficiency. The laser is less prone to deformation due to external forces or vibrations during the cutting process and maintains stable precision even after long-term, high-frequency operation.

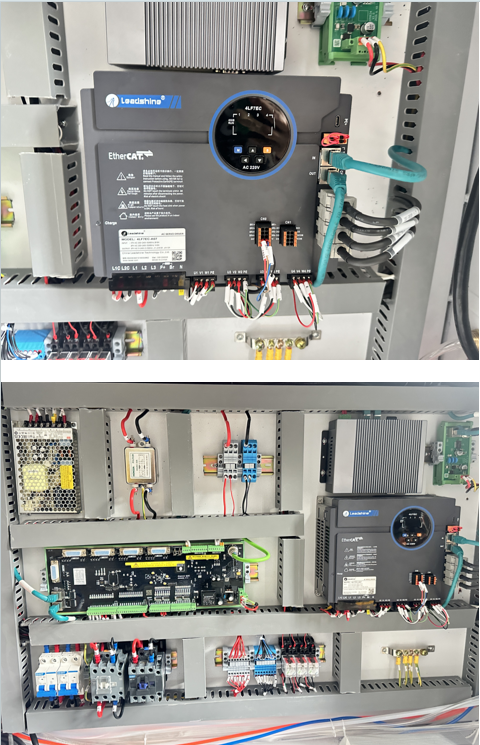

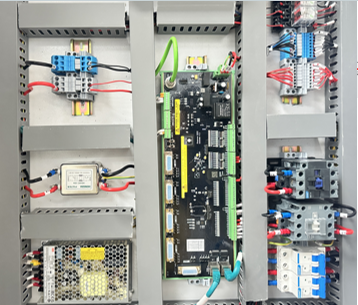

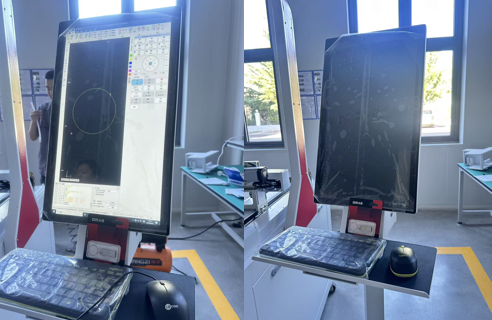

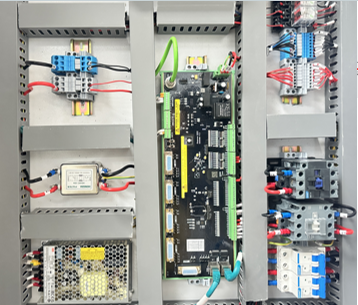

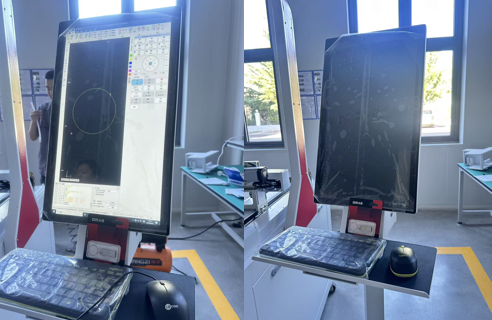

control system

The control system boasts high-precision control capabilities, employing precise control algorithms and high-performance servo motors, achieving positioning accuracy down to the micrometer level. Key parameters such as laser power and cutting speed are monitored in real-time by sensors and transmitted to the control system via a high-speed communication interface. After processing and analysis, the system automatically adjusts processing parameters to achieve closed-loop control, ensuring processing quality.

Electrical components

The voltage signal is converted into torque and speed to drive the controlled object, ensuring the cutting accuracy, positioning speed and repeatability of the laser cutting machine.

Smart handle

Features include smart connectivity, one-handed operation, and a comfortable grip; it can be magnetically attached to any sheet metal surface. It boasts a wireless design, long battery life, and a logically laid-out function button layout.

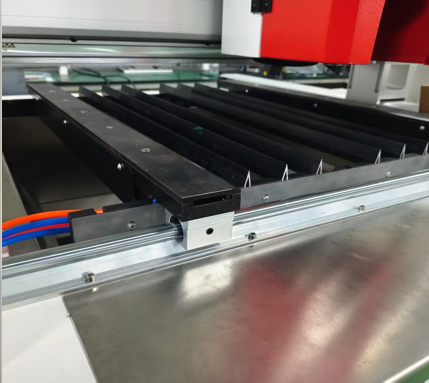

pneumatic clamps

A crucial component for fixing the workpiece to be cut, ensuring cutting accuracy and efficiency.

oil-water separator

Oil-water separators can efficiently remove oil mist, moisture, and dust particles from compressed air, stabilize air output, ensure cutting quality, and reduce equipment failure rate.

module

The XYZ axis modules work together to achieve three-dimensional spatial movement of the laser cutting head. They operate stably, are precisely positioned, and have low noise. They can be used to achieve precise movement and positioning of the laser cutting head, thereby improving cutting efficiency and quality.

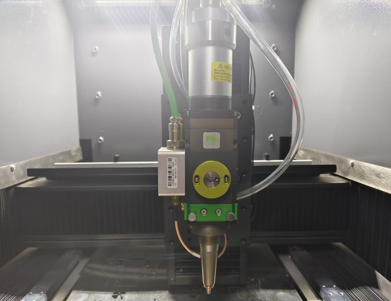

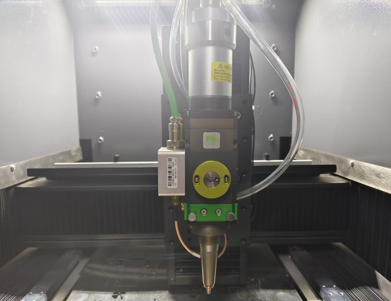

cutting head

Features:

1.High Precision & Stability

2.Wide Power Compatibility

3.Intelligent Control System

emergency stop

Emergency power outage; fault lockout; full machine linkage.

Exhaust vent

To prevent dust from the smoke from adhering to precision components such as the laser head lens, thus extending the lifespan of electrical components and ensuring cutting accuracy.

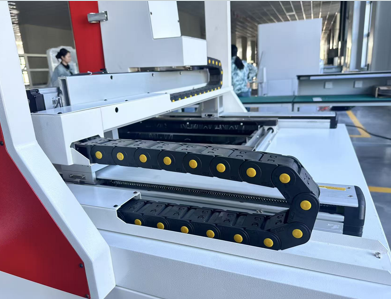

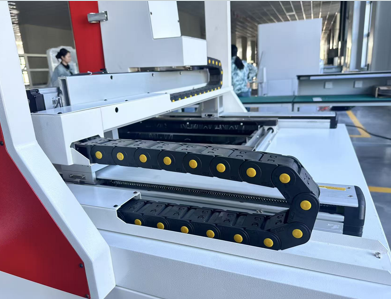

tank chain

This device protects the internal cables, oil pipes, air pipes, and other pipelines of a laser cutting machine, providing traction and protection for these pipelines during equipment operation.

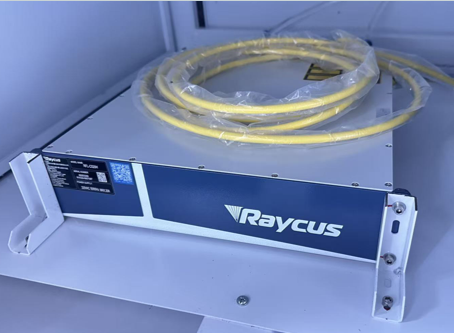

RAYCUS lasers come standard with an 800W output, boasting high photoelectric conversion efficiency and low energy consumption. Their superior beam quality delivers more precise cutting and welding results. Precise matching of optimal parameter combinations meets diverse processing needs. Adaptable to various materials, they offer efficient solutions to processing challenges in different metals.

Real-time monitoring: Allows operators to stay informed about equipment operation.

• Cutting control: Supports professional laser cutting control software.

• Fault diagnosis: Helps operators quickly locate and resolve problems.

Working samples

About us

Related Production Line Machines You Might Be Interested In:

Technical data

Precision Cutting Product Details | |||

project | Brand | brand location | Specification |

laser source | jpt /Raycus /MAX | shenzhen /wuhan | 1500/2000/3000W |

system | raytool | shanghai | XC3000S |

laser head | raytool | BM110 | |

Pneumatic device | SMC | Japan | ITV10150-312L |

motor | lead shine | shenzhen | ACMOH-0604 |

servo system | lead shine | 4LF7EC-A07 | |

module | SKR | koran | X650Y650Z100 |

water chiller | s&a hanli | guangzhou /wuhan | 1500/2000/3000W |

High pressure valve | SMC | Japan | VX232RAXHH |

Electrical components | yijia | zhejiang | Industrial grade |

Machine parts

Optical Section-Laser Generator

Transmission system

Achieving high-precision linear motion and ensuring transmission stability directly determine the dimensional accuracy and processing efficiency of laser cutting. High transmission efficiency reduces motor energy consumption while allowing for faster and smoother axis movement, thus improving cutting efficiency. The laser is less prone to deformation due to external forces or vibrations during the cutting process and maintains stable precision even after long-term, high-frequency operation.

control system

The control system boasts high-precision control capabilities, employing precise control algorithms and high-performance servo motors, achieving positioning accuracy down to the micrometer level. Key parameters such as laser power and cutting speed are monitored in real-time by sensors and transmitted to the control system via a high-speed communication interface. After processing and analysis, the system automatically adjusts processing parameters to achieve closed-loop control, ensuring processing quality.

Electrical components

The voltage signal is converted into torque and speed to drive the controlled object, ensuring the cutting accuracy, positioning speed and repeatability of the laser cutting machine.

Smart handle

Features include smart connectivity, one-handed operation, and a comfortable grip; it can be magnetically attached to any sheet metal surface. It boasts a wireless design, long battery life, and a logically laid-out function button layout.

pneumatic clamps

A crucial component for fixing the workpiece to be cut, ensuring cutting accuracy and efficiency.

oil-water separator

Oil-water separators can efficiently remove oil mist, moisture, and dust particles from compressed air, stabilize air output, ensure cutting quality, and reduce equipment failure rate.

module

The XYZ axis modules work together to achieve three-dimensional spatial movement of the laser cutting head. They operate stably, are precisely positioned, and have low noise. They can be used to achieve precise movement and positioning of the laser cutting head, thereby improving cutting efficiency and quality.

cutting head

Features:

1.High Precision & Stability

2.Wide Power Compatibility

3.Intelligent Control System

emergency stop

Emergency power outage; fault lockout; full machine linkage.

Exhaust vent

To prevent dust from the smoke from adhering to precision components such as the laser head lens, thus extending the lifespan of electrical components and ensuring cutting accuracy.

tank chain

This device protects the internal cables, oil pipes, air pipes, and other pipelines of a laser cutting machine, providing traction and protection for these pipelines during equipment operation.

RAYCUS lasers come standard with an 800W output, boasting high photoelectric conversion efficiency and low energy consumption. Their superior beam quality delivers more precise cutting and welding results. Precise matching of optimal parameter combinations meets diverse processing needs. Adaptable to various materials, they offer efficient solutions to processing challenges in different metals.

Real-time monitoring: Allows operators to stay informed about equipment operation.

• Cutting control: Supports professional laser cutting control software.

• Fault diagnosis: Helps operators quickly locate and resolve problems.

Working samples

About us

Related Production Line Machines You Might Be Interested In: