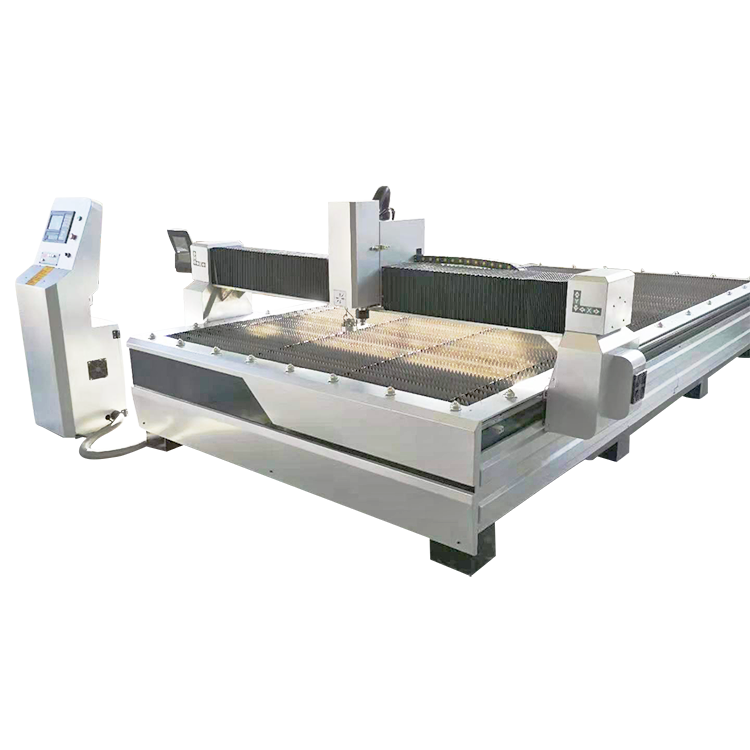

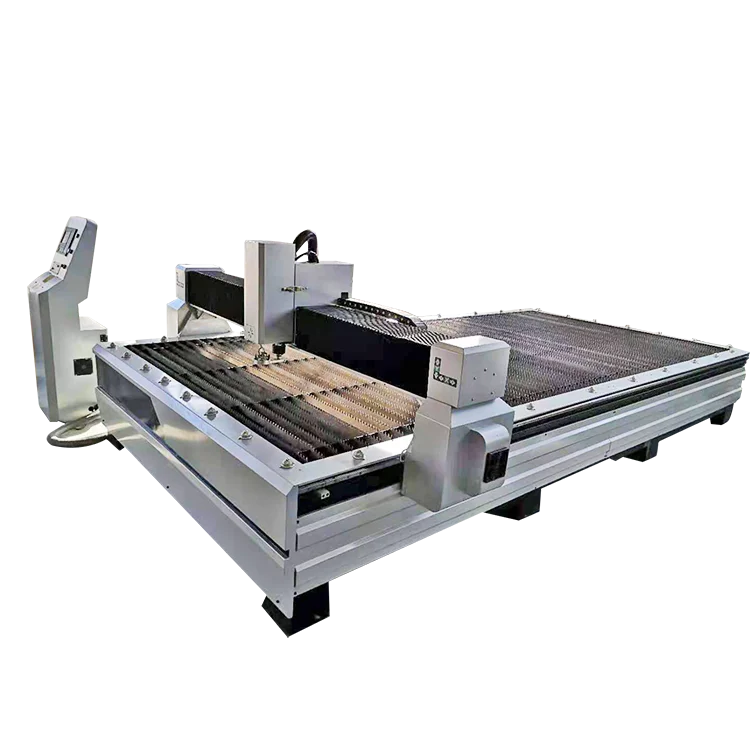

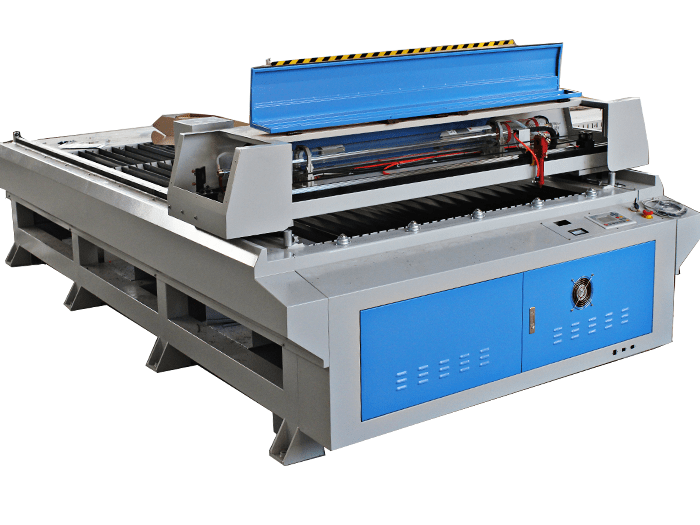

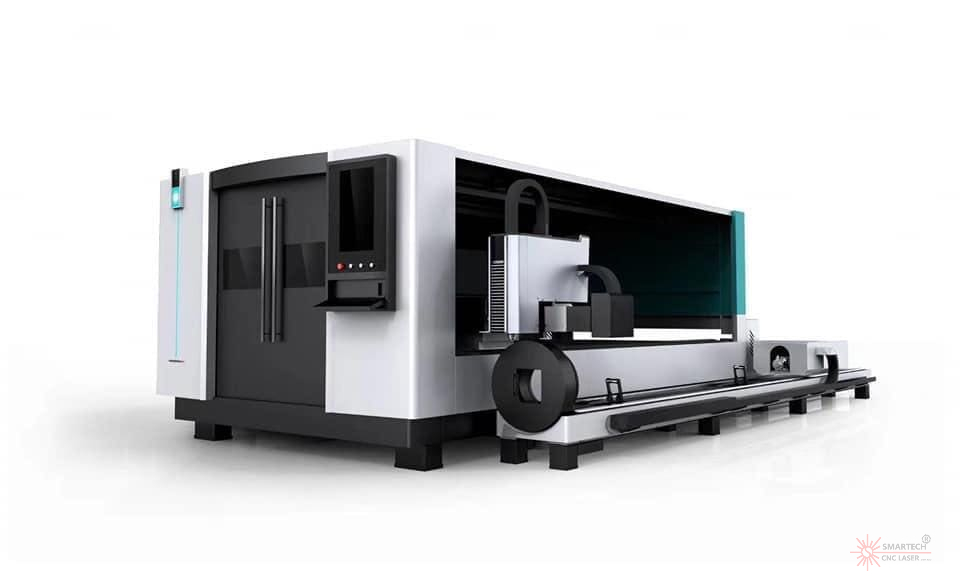

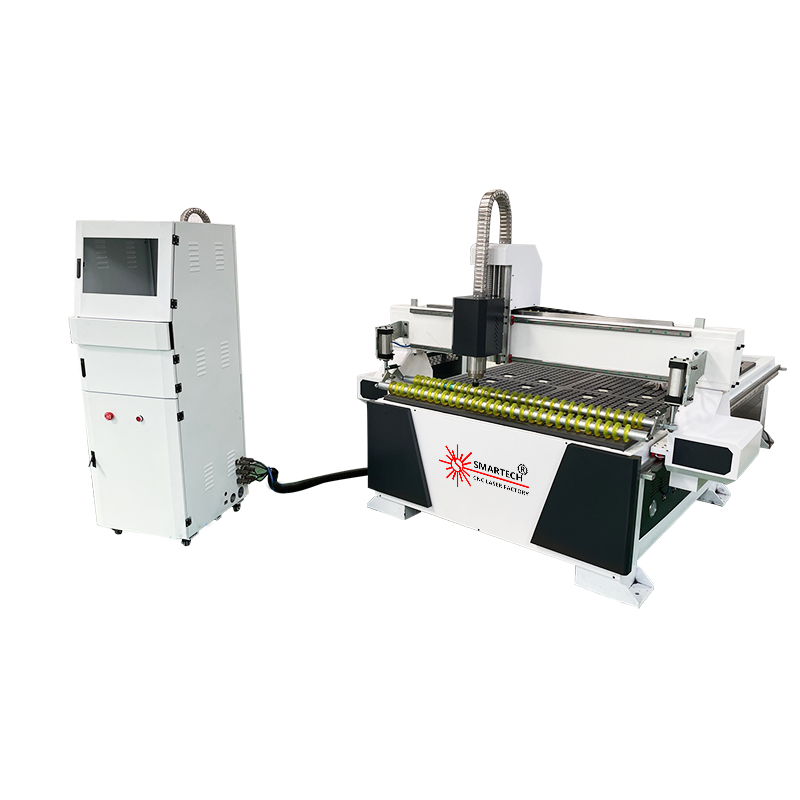

1. Heavy duty machine structure

2. 1500*3000mm working area

3. USA Hypertherm plasma power supply

4. Starfire control system

5. High sensitive auto Arc pressure control

6. High precision Square linear guide raill

7. High precision rack and pinion transmission

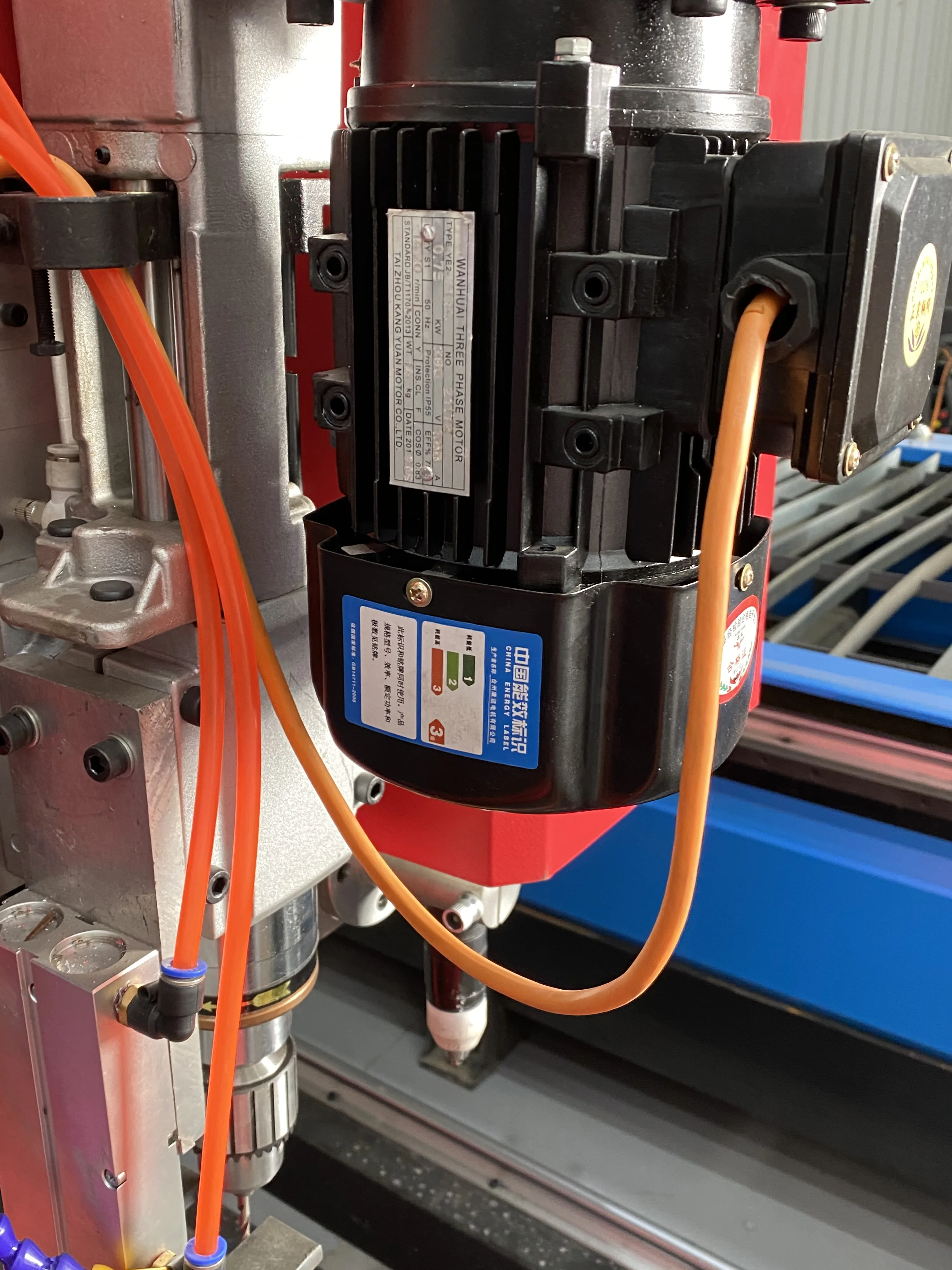

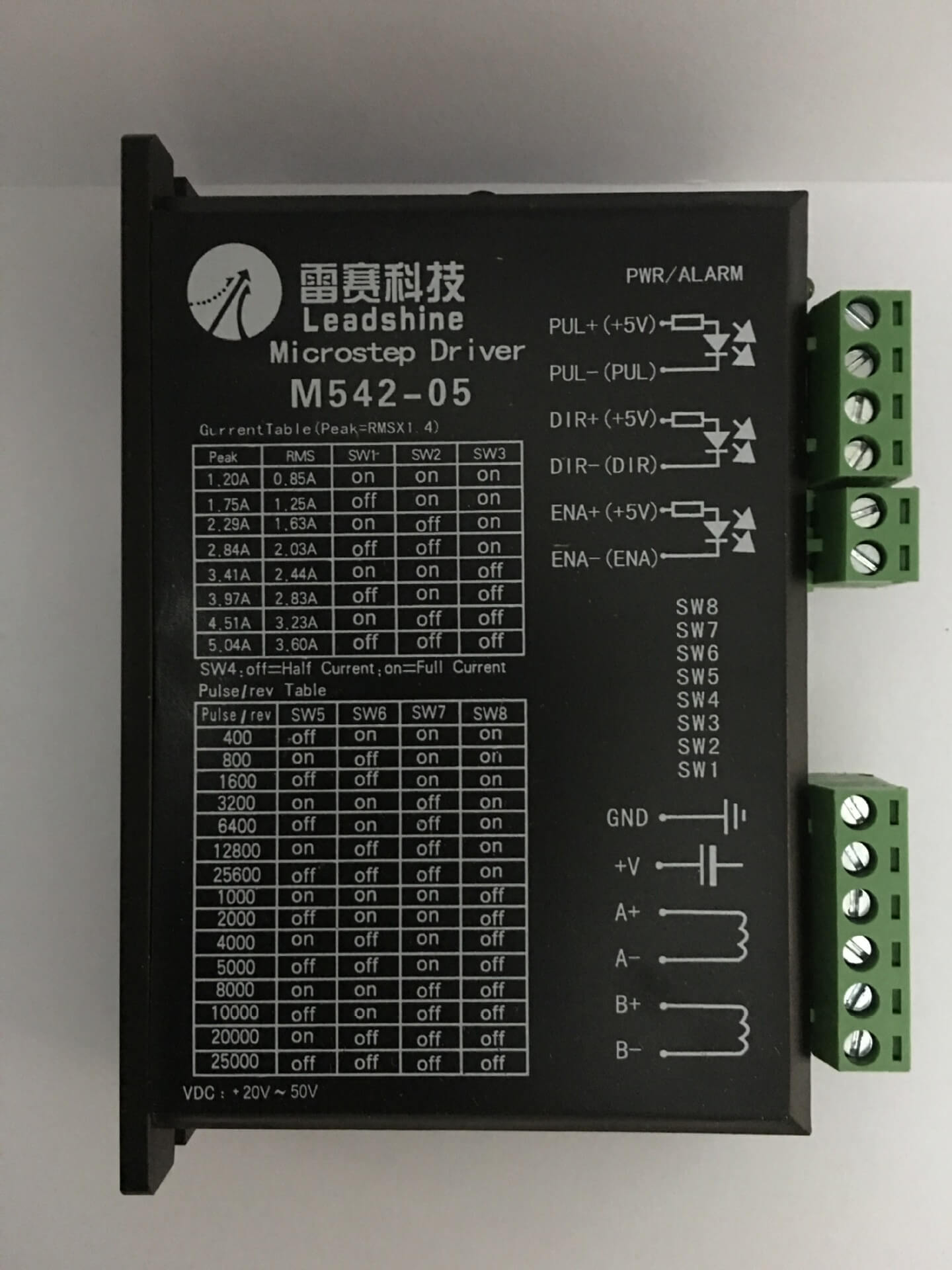

8. High precision stepper motor,Leadshine drivers

9. Tool box with some consumable parts

10. 8G U disk memory, 2G processing file inside

2. 1500*3000mm working area

3. USA Hypertherm plasma power supply

4. Starfire control system

5. High sensitive auto Arc pressure control

6. High precision Square linear guide raill

7. High precision rack and pinion transmission

8. High precision stepper motor,Leadshine drivers

9. Tool box with some consumable parts

10. 8G U disk memory, 2G processing file inside