| Availability: | |

|---|---|

SSC1325/1530/2030

SMARTECH

9KW

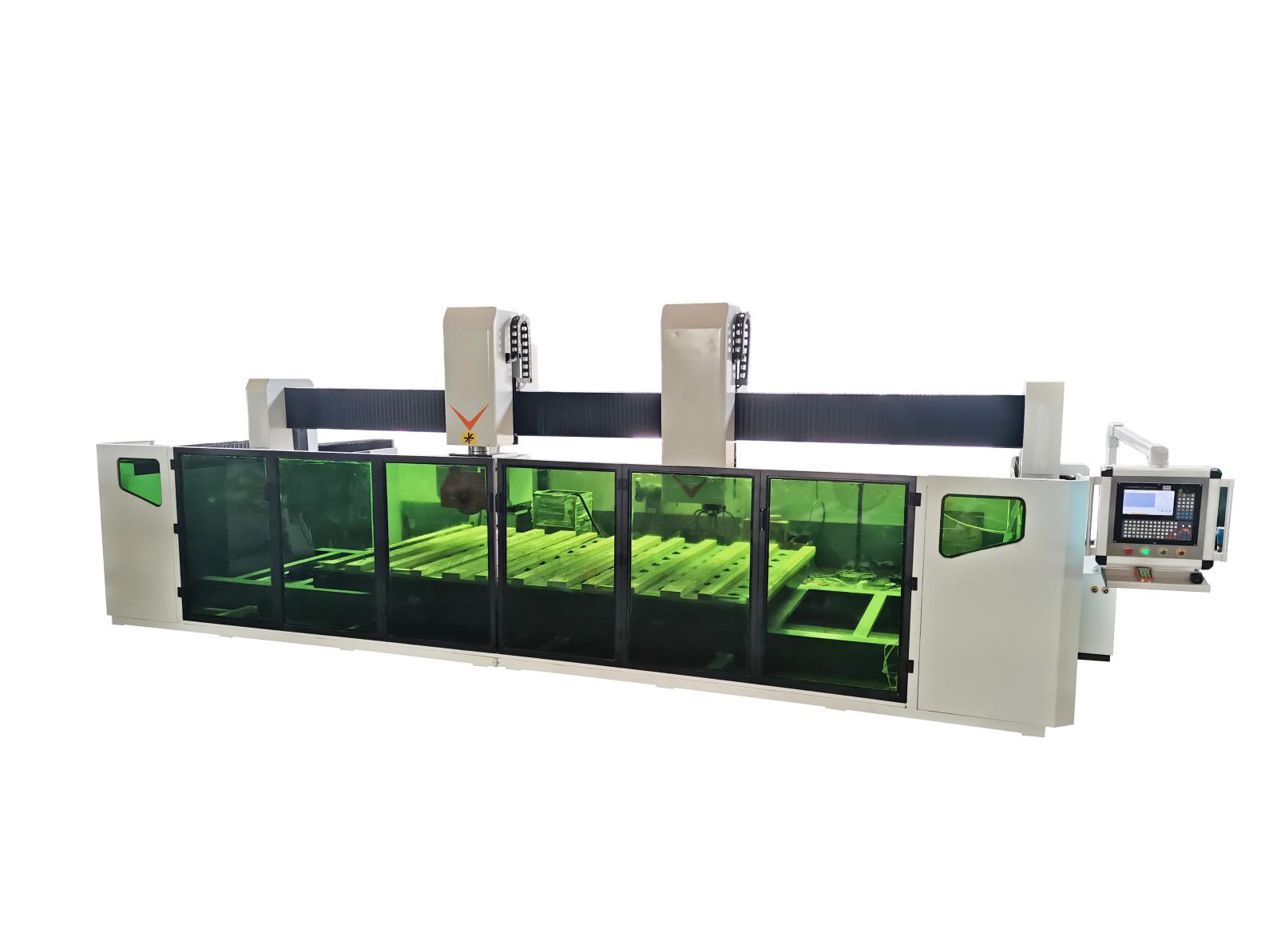

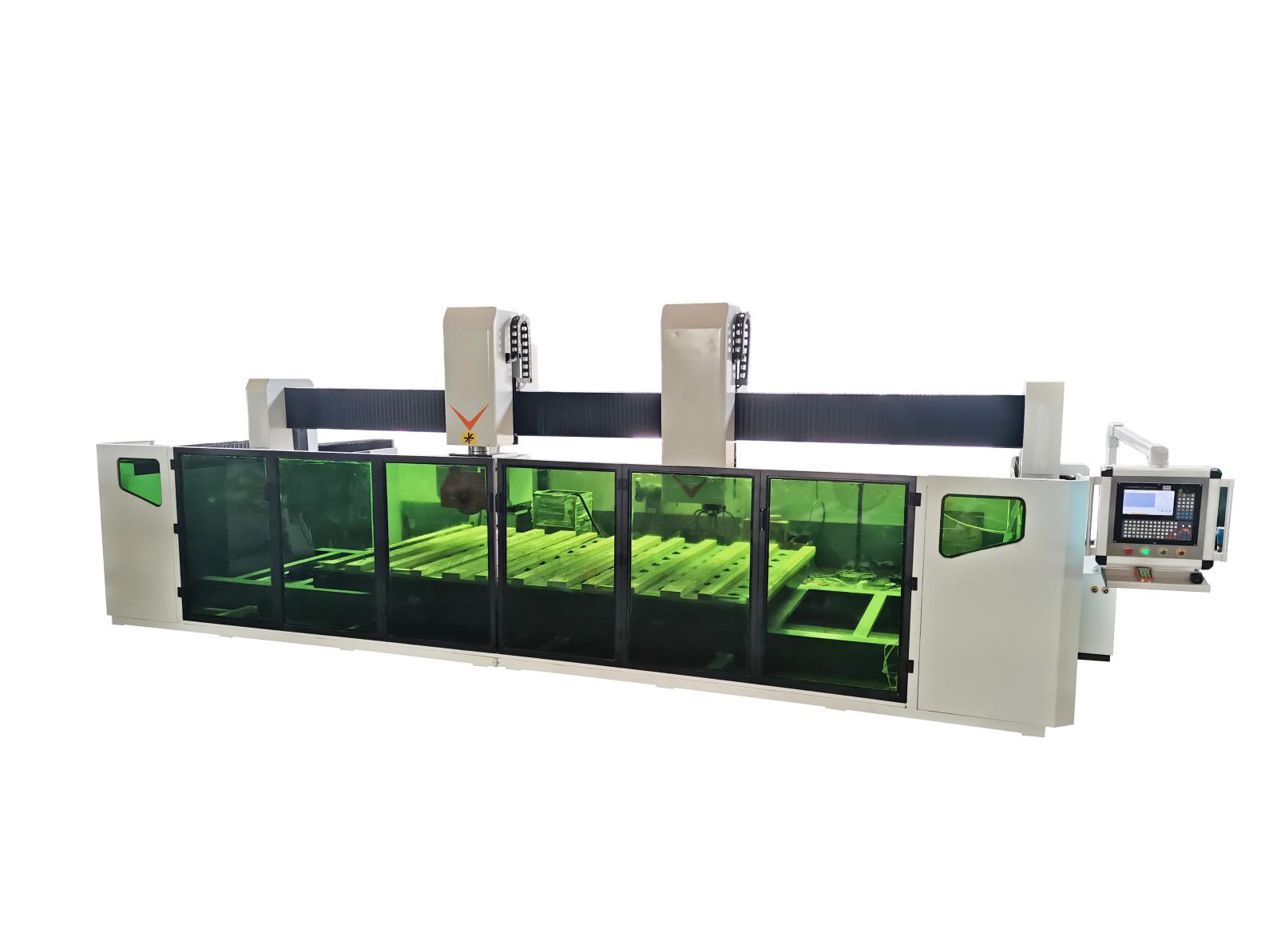

Bridge Saw Cutting & Polishing Machine for countertops#CE standard #Working area:3200*2000mm*400mm #Saw head power: 13KW #Polishing motor:7.5KW(BT40) #Turnover table:0-85o fluid closewise #Motor:Taiwan Servo AC motor & driver #Control system:Customized #Rails:Taiwan HIWIN 30 #Tapping machine power:7.5KW (ER32) Blade diameter:350mm (inner hole diameter:50mm) #Holder:sucking disc #Strong Seamless Steel frame #3 Years’ warranty,Lifetime after sale service #On-site technicians are available.

Application:

2.Machinable Materials: quartz stone, marble, artificial stone, granite, artificial stone, slab,rock platnd other materialADVANTAGE:one device has the function of two devices.on the left is saw blade cutting (cross cutting,vertical cutting,miter cutting in any direction ,circle fan,diamond,horse belly...)The double spindle on the right side can be used for polishing,grinding basin holes cutting,edge mofelling etc)it covers small area and has complete functions. The supporting measuring instrumercan be used for dust-free installation.

Features:1.The machine head can swing at any angle and can cut the plate at any angle and shape: horizontal cutting, longitudinal cutting, arc cutting, elliptical cutting, and round cutting. The machine can also be used for bump edging. 2.In addition to the cutting shape, it can also cut the large plate with 45° chamfering, opening the basin hole, stove hole, and diagonal cutting 3.The platform can be turned by 85°, which is convenient for loading and unloading. 4.No complicated operations, just input data on the control system 5.Equipped with a grinding wheel device, which can polish the table hole and cutting 6.Fully automatic five-axis infrared bridge cutting machine, multi-language conversion, table top processing can be done by one machine, X-Y-Z-A-B five-axis linkage, a wider range of applications, can realize cutting, chamfering, edging, grooving, drilling, circular arc Other special-shaped processing, simple operation and strong practicability.

1.The machine head can swing at any angle and can cut the plate at any angle and shape: horizontal cutting, longitudinal cutting, arc cutting, elliptical cutting, and round cutting. The machine can also be used for bump edging. 2.In addition to the cutting shape, it can also cut the large plate with 45° chamfering, opening the basin hole, stove hole, and diagonal cutting 3.The platform can be turned by 85°, which is convenient for loading and unloading. 4.No complicated operations, just input data on the control system 5.Equipped with a grinding wheel device, which can polish the table hole and cutting6.Fully automatic five-axis infrared bridge cutting machine, multi-language conversion, table top processing can be done by one machine, X-Y-Z-A-B five-axis linkage, a wider range of applications, can realize cutting, chamfering, edging, grooving, drilling, circular arc Other special-shaped processing, simple operation and strong practicability.

Specification

Machine Head

Machine parts

Machine Working Samples

![]()

Bridge Saw Cutting & Polishing Machine for countertops#CE standard #Working area:3200*2000mm*400mm #Saw head power: 13KW #Polishing motor:7.5KW(BT40) #Turnover table:0-85o fluid closewise #Motor:Taiwan Servo AC motor & driver #Control system:Customized #Rails:Taiwan HIWIN 30 #Tapping machine power:7.5KW (ER32) Blade diameter:350mm (inner hole diameter:50mm) #Holder:sucking disc #Strong Seamless Steel frame #3 Years’ warranty,Lifetime after sale service #On-site technicians are available.

Application:

2.Machinable Materials: quartz stone, marble, artificial stone, granite, artificial stone, slab,rock platnd other materialADVANTAGE:one device has the function of two devices.on the left is saw blade cutting (cross cutting,vertical cutting,miter cutting in any direction ,circle fan,diamond,horse belly...)The double spindle on the right side can be used for polishing,grinding basin holes cutting,edge mofelling etc)it covers small area and has complete functions. The supporting measuring instrumercan be used for dust-free installation.

Features:1.The machine head can swing at any angle and can cut the plate at any angle and shape: horizontal cutting, longitudinal cutting, arc cutting, elliptical cutting, and round cutting. The machine can also be used for bump edging. 2.In addition to the cutting shape, it can also cut the large plate with 45° chamfering, opening the basin hole, stove hole, and diagonal cutting 3.The platform can be turned by 85°, which is convenient for loading and unloading. 4.No complicated operations, just input data on the control system 5.Equipped with a grinding wheel device, which can polish the table hole and cutting 6.Fully automatic five-axis infrared bridge cutting machine, multi-language conversion, table top processing can be done by one machine, X-Y-Z-A-B five-axis linkage, a wider range of applications, can realize cutting, chamfering, edging, grooving, drilling, circular arc Other special-shaped processing, simple operation and strong practicability.

1.The machine head can swing at any angle and can cut the plate at any angle and shape: horizontal cutting, longitudinal cutting, arc cutting, elliptical cutting, and round cutting. The machine can also be used for bump edging. 2.In addition to the cutting shape, it can also cut the large plate with 45° chamfering, opening the basin hole, stove hole, and diagonal cutting 3.The platform can be turned by 85°, which is convenient for loading and unloading. 4.No complicated operations, just input data on the control system 5.Equipped with a grinding wheel device, which can polish the table hole and cutting6.Fully automatic five-axis infrared bridge cutting machine, multi-language conversion, table top processing can be done by one machine, X-Y-Z-A-B five-axis linkage, a wider range of applications, can realize cutting, chamfering, edging, grooving, drilling, circular arc Other special-shaped processing, simple operation and strong practicability.

Specification

Machine Head

Machine parts

Machine Working Samples

![]()