| Availability: | |

|---|---|

CNC Router

SMARTECH

CNC Router

2500x1300x200mm

380V

write

1.The machine from auto loading,optimize rough shape cutting ,vertical punching to auto unloading without stopping. Working process without interruption,achieve the max efficiency output.

2.The control interface of the machine design humanization,quite easy operation.the operator can operate it just with few hours training. The machine motion agility high speed and high efficiency. It can help you achieve off-take potential leap.

3.Stable performance,it adopts some import parts,such as high-power air cooling spindle,Japan Servo drive system,Planetary Reducer,France Schneider electrical components and so on.

4.The table is double-deck vacuum suck table,it can tightly suck different area materials.

No. Configurations OPTION

Equipment SA Series Disc Automatic tools changer

Machine Body Thickening of lathe bed,high temperature heat treatment,machining center,high precision, long life

Working area 900&*600mm Weight 2800Kg

Speed Idling 60-80m/min Working speed:20m/min

Rail Y axis 3.0 X,Z Axis 2.5

Rack screw rack

Main parts Yaskawa Servo servo motor and drivers DELTA SERVO

Inverter 11KW/380V Inverter from Taiwan

Syntec Conttroler imported from Taiwan MACH3/OSAI

Standard huge control box

9KW Air cooling ATC Spindle Italy ISO30ER32 Double Spindles

8 pieces tools holder

HIWIN Rail for 3 axis Helical tooth rack

Original TBI Ball screw

Electricity parts: Original Schneider

Table Double thickening mesa, suction bigger and more uniform

Automatic tool sensor,Automatic lubricating system

Ancillary attachment Dust collector double bags、Brush、Dust pipes、Dust holder

Vacuum pump

ISO30 ER32 Collet 12.7 8 pieces

Collet 6 2 pieces;Collet 4 2 pieces;Spanners 2 sets

Voltage 380V 3 phase 220V-240V

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A:Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways?

A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your

workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China, about 2hours train from Beijing and Shanghai.

-Q Can I arrange sample for cutting test?

A:Yes, always welcome.

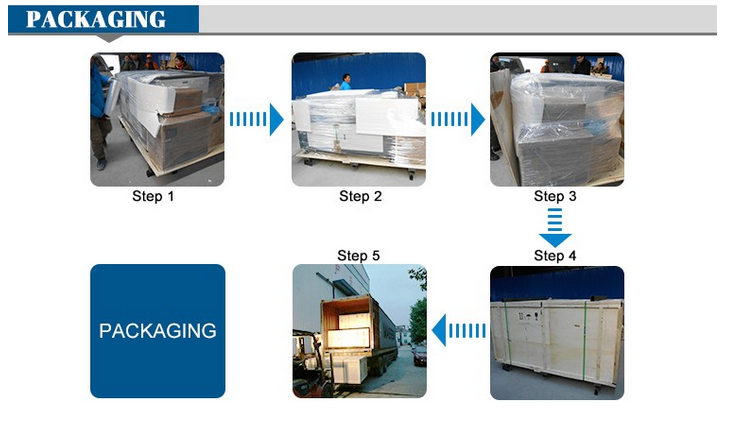

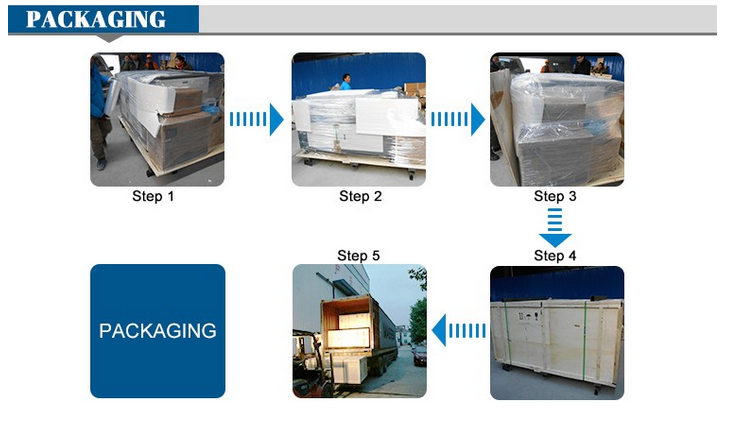

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality

control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95% customers can learn by themselves.

1.The machine from auto loading,optimize rough shape cutting ,vertical punching to auto unloading without stopping. Working process without interruption,achieve the max efficiency output.

2.The control interface of the machine design humanization,quite easy operation.the operator can operate it just with few hours training. The machine motion agility high speed and high efficiency. It can help you achieve off-take potential leap.

3.Stable performance,it adopts some import parts,such as high-power air cooling spindle,Japan Servo drive system,Planetary Reducer,France Schneider electrical components and so on.

4.The table is double-deck vacuum suck table,it can tightly suck different area materials.

No. Configurations OPTION

Equipment SA Series Disc Automatic tools changer

Machine Body Thickening of lathe bed,high temperature heat treatment,machining center,high precision, long life

Working area 900&*600mm Weight 2800Kg

Speed Idling 60-80m/min Working speed:20m/min

Rail Y axis 3.0 X,Z Axis 2.5

Rack screw rack

Main parts Yaskawa Servo servo motor and drivers DELTA SERVO

Inverter 11KW/380V Inverter from Taiwan

Syntec Conttroler imported from Taiwan MACH3/OSAI

Standard huge control box

9KW Air cooling ATC Spindle Italy ISO30ER32 Double Spindles

8 pieces tools holder

HIWIN Rail for 3 axis Helical tooth rack

Original TBI Ball screw

Electricity parts: Original Schneider

Table Double thickening mesa, suction bigger and more uniform

Automatic tool sensor,Automatic lubricating system

Ancillary attachment Dust collector double bags、Brush、Dust pipes、Dust holder

Vacuum pump

ISO30 ER32 Collet 12.7 8 pieces

Collet 6 2 pieces;Collet 4 2 pieces;Spanners 2 sets

Voltage 380V 3 phase 220V-240V

-Q What is the payment terms?

A:Western Union,Cash,T/T

-Q How long is the delivery date?(After getting the deposit)

A:Delivery time is 5-7 working days for standard machine models,please confirm with us before payment.

-Q How about the shipping ways?

A:By sea or by air

-Q Is on site training is available ?

A: Yes, we could provide training in our factory or at your

workshop after machine arrival.

-Q Where is your factory located? How can I visit there?

A:Jinan City, Shandong Province, China, about 2hours train from Beijing and Shanghai.

-Q Can I arrange sample for cutting test?

A:Yes, always welcome.

-Q How about your laser machine package?

A: Standard export wood package with free fumigation

-Q How about the quality guarantee period?

A:5 Years for whole machine

-Q How can you guarantee the production quality ?

A:We have 15years experience of QC team; strictly quality

control system in our production process.

-Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user’s manual along with the machine. 95% customers can learn by themselves.