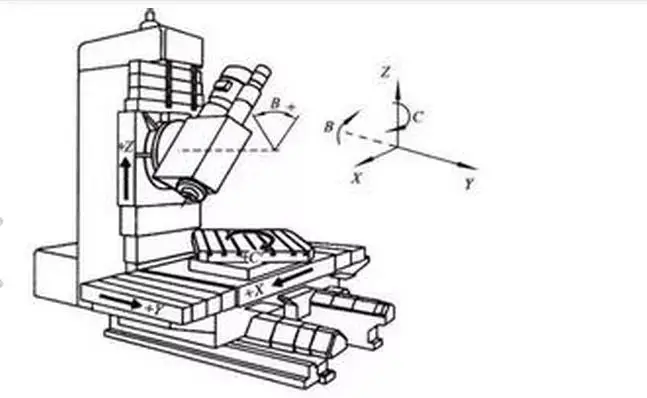

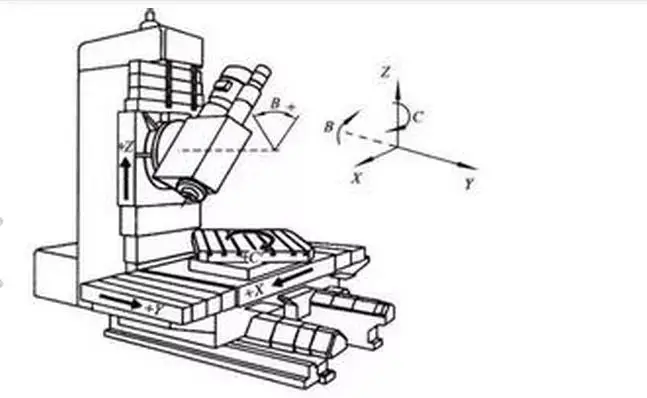

Specification Standard specisications SW1325-5 AXIIS Work Area 1220×2440×950mm Spindle power 6KW Air cooling spindle Max travel speed 80m/min Positioning Accuracy 0.01/2000mm Drive motor YASKAWA servo motors and drivers Max working speed 50m/min Working Voltage AC380V/3PH/50HZ Command Language G code Spindle speed 5000-24000rpm Interface USB Running Environment Temperature: 0-45 degree Relative Humidity: 30%-75% Tools 3.175 / 6 / 12.7 / 16 / 20 Control 5 Axis SYNTEC control system Key word cnc router 5 axis