Views: 60006 Author: Site Editor Publish Time: 2023-07-13 Origin: Site

一、1000W Fiber Laser Cutting Machine for Sheet Metal Stainless Steel

Feature

1.The machine warranty is 5 years, once the machine parts was bad, we will send you a new one free

2.We support one year change a new one machine free

3.Before shipping, we test the machine over 24 hours, be sure you can use it directly once you received it

4.Machine with computer, friendly operate system

5. German LROSA-TW linear guide and Rack fiber laser cutting machine transmission system, high cutting efficiency

6.Low Cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption

7. We have technician team in CA, USA, MS, USA. free door to door training and 24 hours online serive

二、1500W Precision Fiber Laser Cutting Machine Metal

Machine is suitable for ultra precision cutting, such as carbon steel, stainless steel, galvanized sheet, aluminum alloy, titanium alloy, gold, silver, aluminum, brass, copper and tight sheet metal fittings, etc

Features

Ultra-high precision linear motor module

Compact structure & low power loss

High position accuracy and re-positioning accuracy

Higher speed and acceleration

Excellent follow-up performance

Safe, reliable, long service life

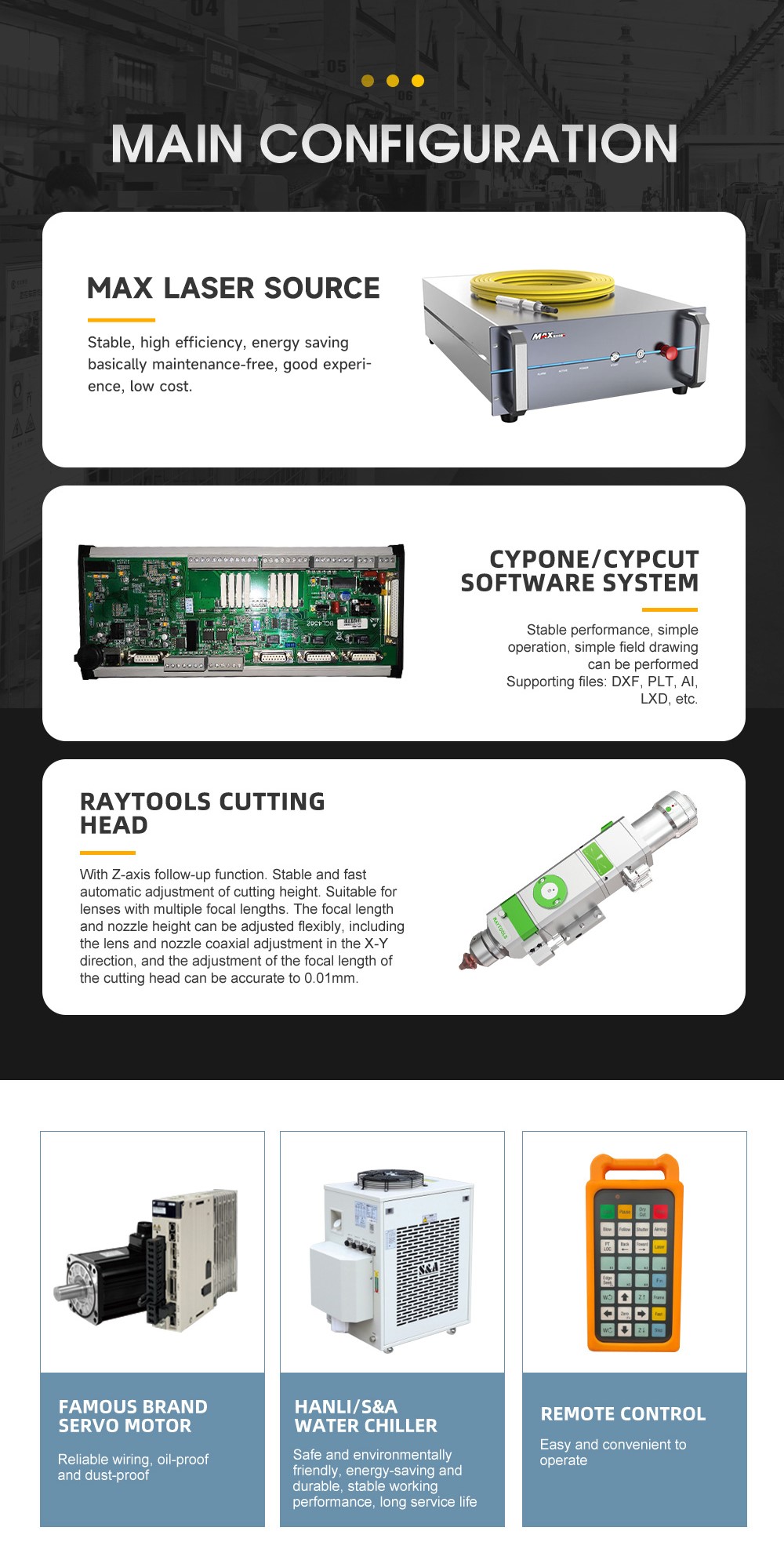

Main configuration

When selecting a fiber laser cutting machine, one of the most important considerations is the power of the laser. The two most common power options are 1000W and 1500W lasers, and the choice between them depends on your specific cutting requirements. Below, we compare the features and applications of these two models to help you make an informed decision.

The 1000W Fiber Laser Cutting Machine is an excellent choice for businesses that focus on cutting thin to medium-thick materials with high precision and speed. The 1000W power output makes it ideal for cutting carbon steel, stainless steel, aluminum, and other non-ferrous metals up to moderate thickness.

Precision and Speed:

The 1000W fiber laser cutting machine delivers high-precision cuts at impressive speeds. It is particularly effective for fine detailing and cutting thin materials (up to 6-8mm for steel and 2-3mm for stainless steel) with a clean edge and minimal thermal distortion.

Versatility:

This machine is suitable for a wide range of materials, including stainless steel, carbon steel, aluminum, and brass. It can handle laser engraving, marking, and cutting tasks efficiently.

Energy Efficiency:

The 1000W laser consumes less power compared to higher wattage machines, making it a cost-effective solution for businesses with smaller-scale operations or for those cutting thinner materials.

Low Maintenance:

Fiber laser machines require minimal maintenance. The 1000W version is equipped with advanced optical fibers, ensuring that the laser source is durable and requires less frequent servicing.

Small to medium-sized businesses with moderate cutting needs.

Thin materials, especially sheet metal up to 6mm in thickness.

Metal fabrication, signage, and automotive parts.

Advertising signs and metal signs.

Precision cutting of thin steel and aluminum.

Customized parts for small to medium-sized production runs.

The 1500W Fiber Laser Cutting Machine is designed for businesses that require high-power cutting for thicker materials and faster production speeds. This machine is more suitable for cutting thick metals and high-volume production, making it the ideal choice for industries that deal with heavy-duty materials.

Increased Cutting Thickness:

The 1500W fiber laser can easily cut through thicker materials, including carbon steel (up to 12-15mm), stainless steel (up to 8mm), and aluminum (up to 5-6mm), making it perfect for heavy-duty cutting applications.

Higher Speed:

The 1500W laser offers faster cutting speeds, allowing businesses to increase throughput and reduce production times. This model is ideal for industries that require high-volume cutting and need to meet tight deadlines.

Superior Efficiency and Quality:

The increased power translates into faster piercing and cutting speeds. Despite cutting thicker materials, the 1500W laser still produces clean, high-quality cuts with minimal burr formation and small heat-affected zones.

Reduced Operating Costs for Larger Production:

For businesses with high production volumes or requirements for cutting thicker sheets of metal, the 1500W model can provide better cost efficiency over time due to faster cutting and fewer process delays.