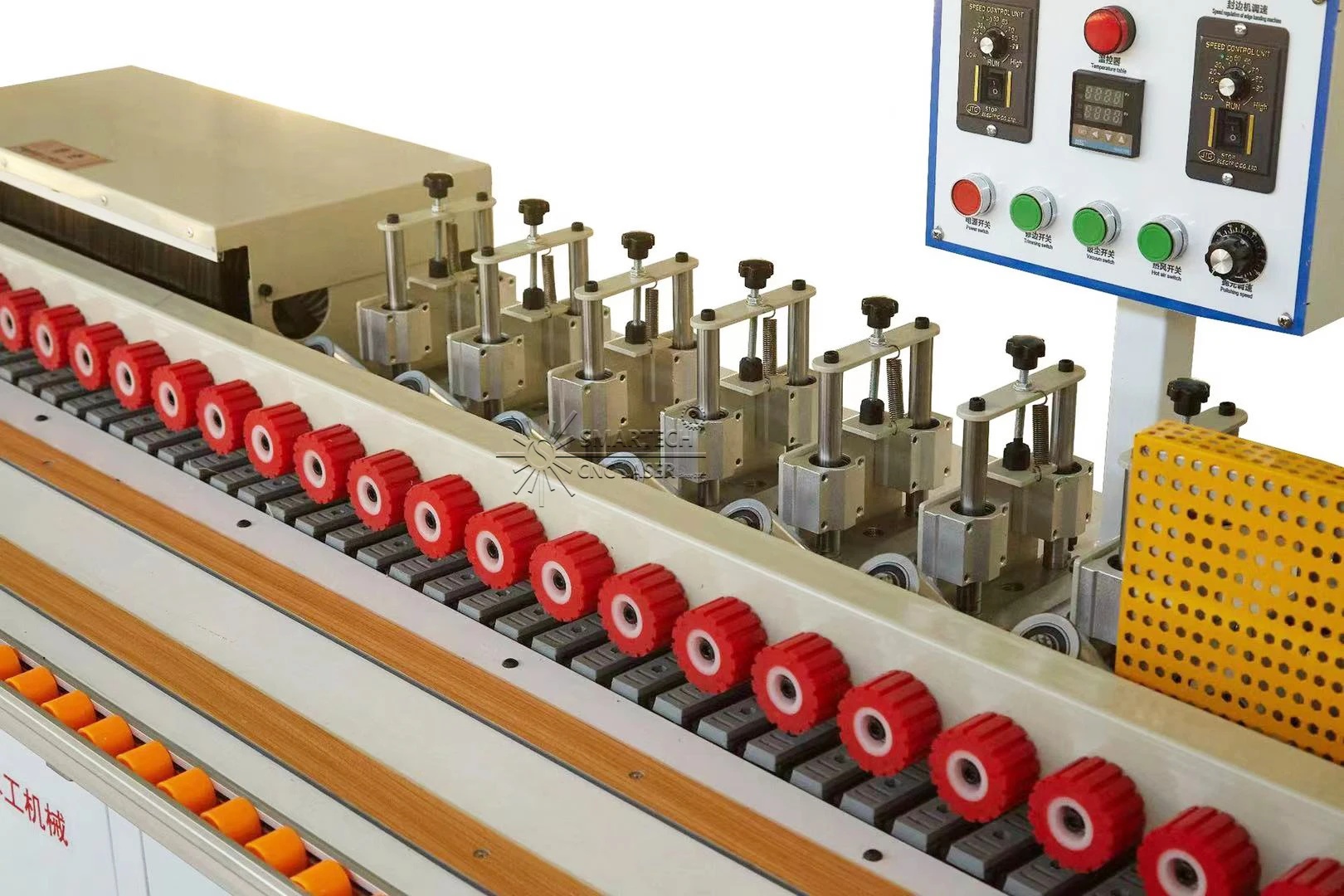

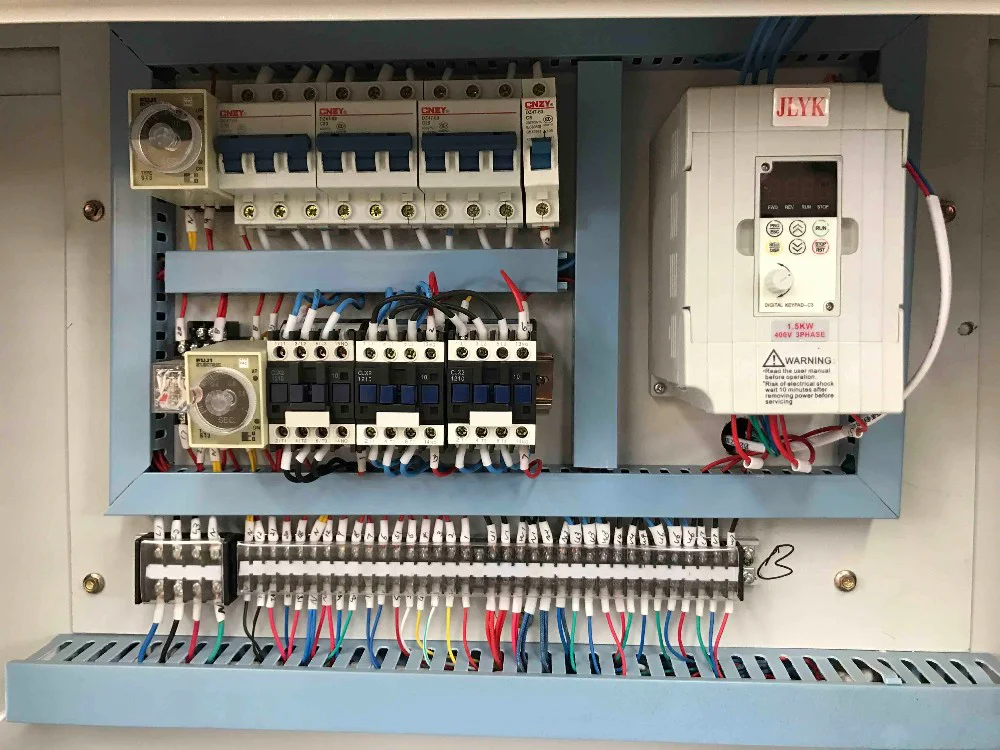

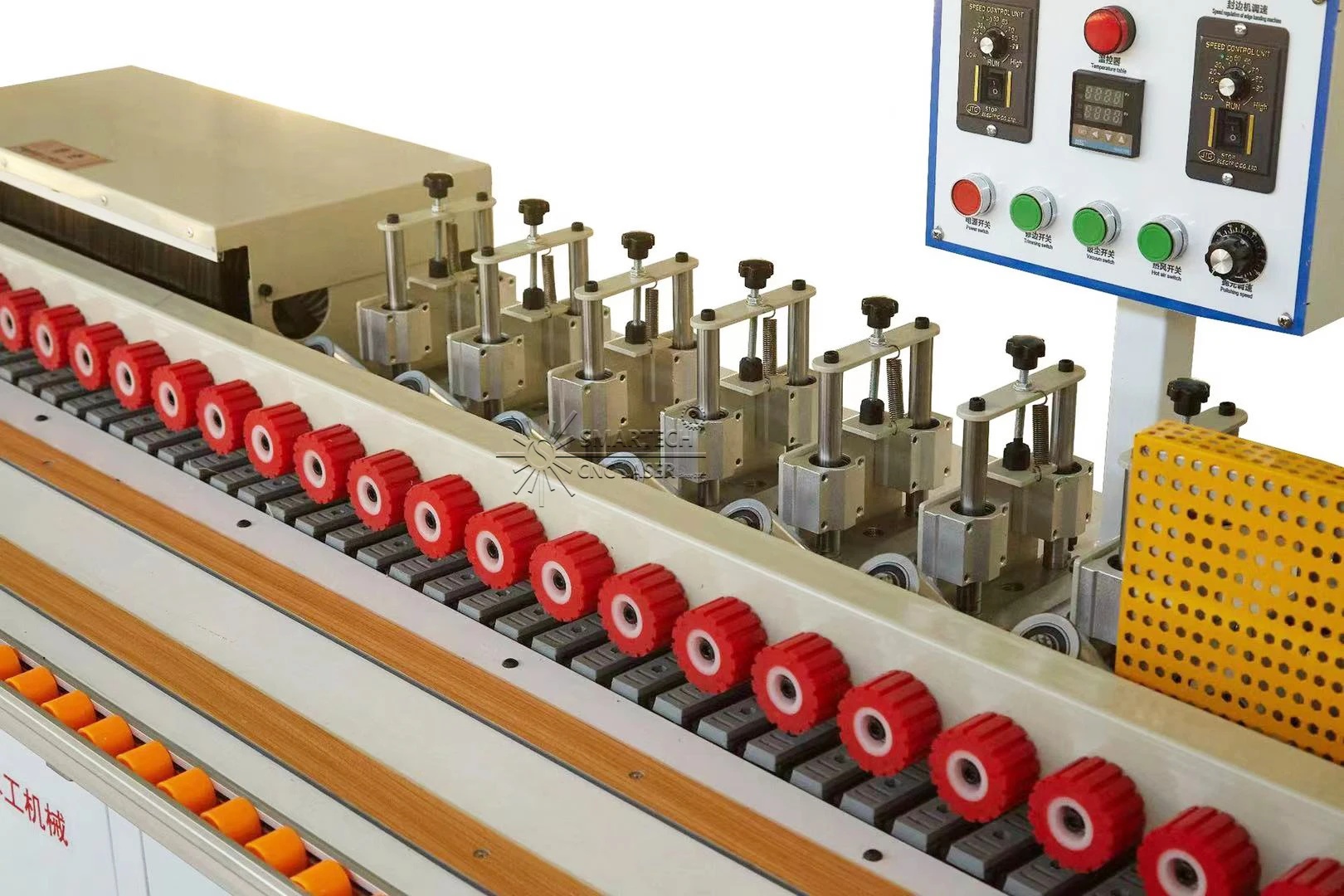

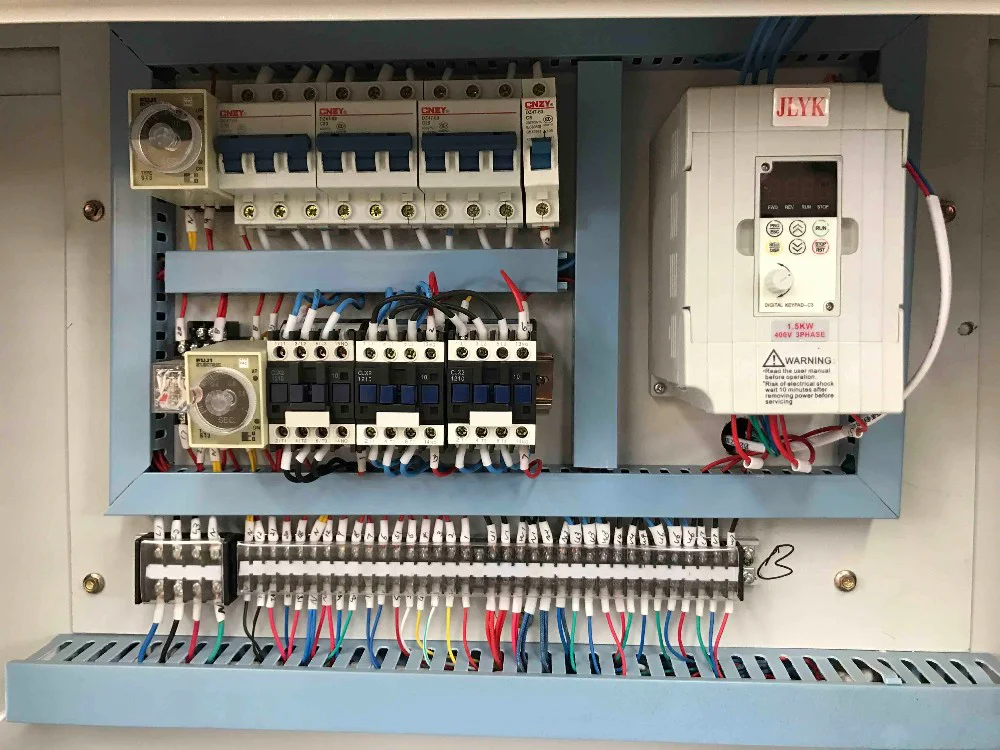

Feed Speed 8-18m/min Rolling edge-enveloping belt thickness 0.4-3mm Rolling edge-enveloping belt height 12-45mm Work piece thickness 10-60mm Panel width≥ 80mm Panel length≥ 120mm Delivery speed of workpiece 11.79m/min Air pressure 0.6-0.8Mpa Motor 3.75KW Heater 0.12kw Workpiece thickness 0.75kw Rubber axle motor 0.37kw Toral power capacity 5.4kw Machine tool dimension 3300mm*800mm*1500mm Weight 1100kg Voltage 380v or as your request Model SE60E SE360A SE360B SE360C SE360YC SE360D SE360F Motor power 4KW 7.4KW 9.4KW 8.5KW 11KW 19KW 15KW Panel width ≥60mm ≥60mm ≥60mm ≥60mm ≥60mm ≥60mm ≥60mm Panel thickness 10~60mm 10~60mm 10~60mm 10~60mm 10~60mm 10~60mm 10~60mm Edge band thickness 0.4~3.0mm 0.4~3.0mm 0.4~3.0mm 0.4~3.0mm 0.4~3.0mm 0.4~3.0mm 0.4~3.0mm Edge band width 12~65mm 12~65mm 12~65mm 12~65mm 12~65mm 12~65mm 12~65mm Feed speed 0~13m/min 0~13m/min 0~13m/min 0~13m/min 0~13m/min 0~13m/min 0~13m/min Working pressure 0.7Mpa 0.7Mpa 0.7Mpa 0.7Mpa 0.7Mpa 0.7Mpa 0.7Mpa

Size (CM) (LWH) 274x85x148 370x93x160 450x93x160 418x93x160 500x93x160 590x93x160 610x93x160

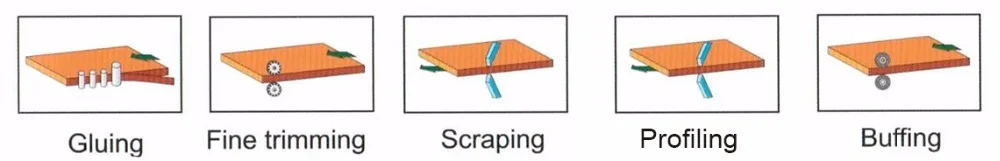

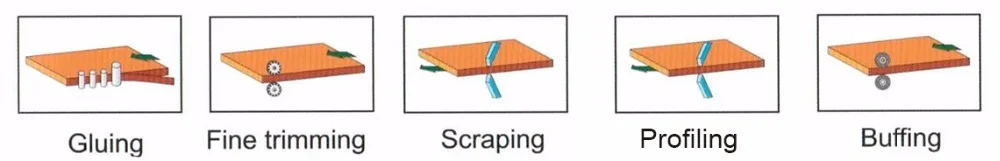

x160E60E gluing,trimming,scrapping and buffing,also with manual end cutting SE360A gluing,end cutting,fine trimming,scrapping and buffing SE360B gluing,end cutting,rough trimming,fine trimming,scrapping and buffing SE360C gluing,end cutting,fine trimming,scrapping,vertical grooving,horizontal grooving and buffing SE360YC pre-milling,gluing,end cutting,rough trimming,fine trimming,scrapping and buffing SE360F pre-milling,gluing,end cutting,fine trimming,corner rounding,scrapping, and buffing SE360D gluing,end cutting,rough trimming,fine trimming,corner rounding,scrapping and buffing